A team of scientists at SERIS has announced the development of a new process for the texturing of diamond wire cut multi-crystalline silicon wafers.

The wet chemical technique etches the wafer surface with nano-scale features, which increase the chance of light bouncing off the surface multiple times and being absorbed by the wafer material. According to SERIS the technique uses proprietary chemicals and is low-cost, scalable and can be easily integrated into cell production lines.

The advent of diamond wire sawing several years ago brought major cost reductions to PV manufacturing, but thanks to the texturing issue the technology was initially limited to mono-crystalline silicon wafer.

Several solutions to this issue are already commercially available, including ‘black silicon’ techniques of reactive ion etching and metal catalyzed chemical etching, and the DW Pretex Process developed by German company Schmid. Despite this, SERIS is confident that its new process offers further benefits to manufacturers, particularly in comparison to the black silicon processes.

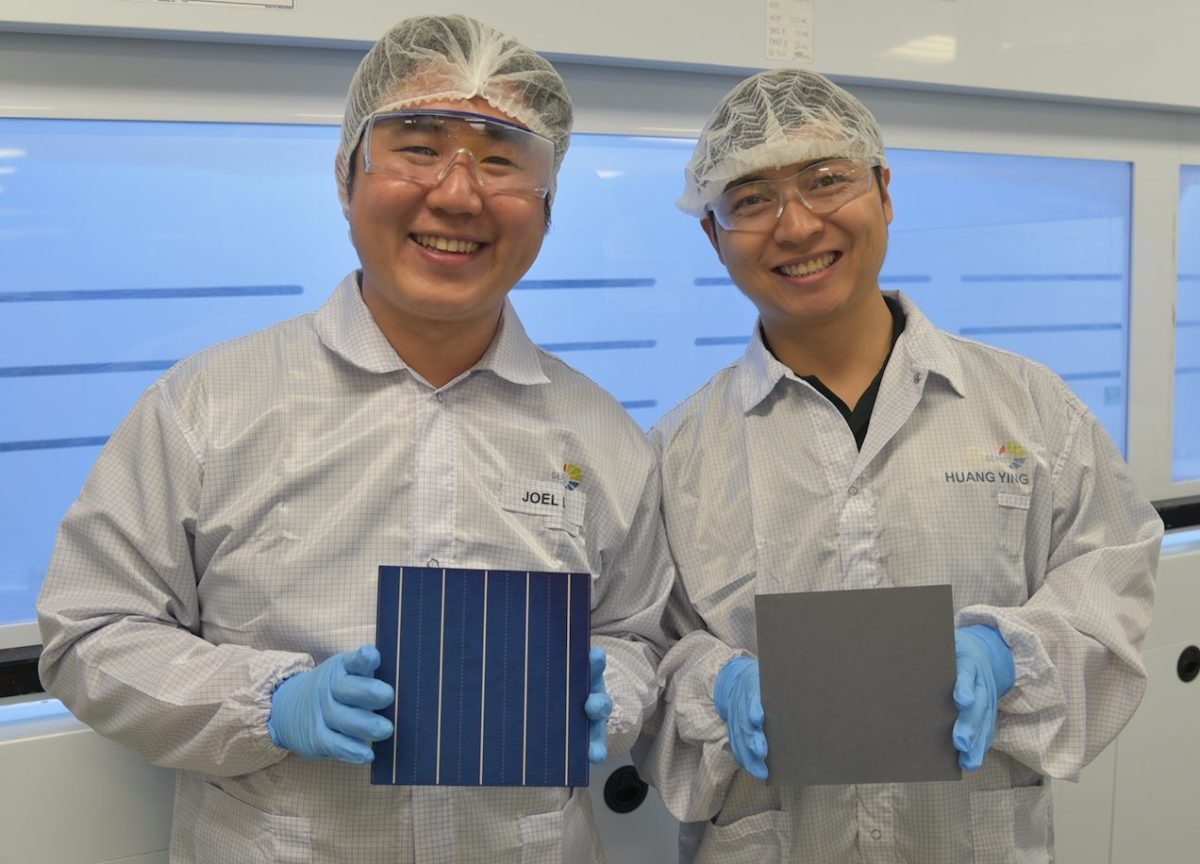

“The two techniques that are commonly used to create a nanoscale texture on DWS mc-Si wafer surfaces are reactive ion etching (RIE) and metal-catalyzed chemical etching (MCCE). The production costs of these two techniques are much higher than those of conventional acid-based texturing, and MCCE involves the use of metallic particles which runs the risk of introducing contaminants to production lines,” says Huang Ying, lead inventor of the DWS wafer texturing technology. “Our technology is simpler, cheaper, metal-free and can achieve cell efficiencies of more than 20%. For these reasons, I strongly believe that our technology can become a mainstream texturing technology used by mc-Si solar cell manufacturers.”

SERIS says that its process has already been recognized by several tier-1 manufacturers, and that it plans to work closely with them to see the process scaled up to large production lines. “As the PV industry experiences a major shift from slurry-cut to DWS mc-Si wafers this year, we believe that this novel technology developed by SERIS will become a mainstream texturing technology for DWS mc-Si wafers,” said SERIS CEO Prof Armin Aberle.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.