From pv magazine, December edition

For manufacturers, the choice of backsheet is crucial. Being the component that will be protecting the module’s inner workings from moisture and adverse weather conditions in the field for its entire working lifetime, backsheet performance simply must live up to supplier promises. As PV finds its way into new regions with tougher climates, and investors expect ever longer working lifetimes from projects, the question only becomes more relevant.

Currently, the bulk of the backsheet market is represented by fluoropolymer materials in various combinations. These are preferred for their proven hydrolytic stability and excellent resistance to weathering effects in various conditions. Such materials – most commonly polyvinyl fluoride (PVF) and polyvinylidene difluoride (PVDF) are combined via lamination with a core layer of an insulating material such as polyethylene terephthalate (PET).

Market shares

The 2018 International Technology Roadmap for Photovoltaics (ITRPV) report estimates that one such three-layer combination, Tedlar-polyester-Tedlar – based on two PVF outer layers with polyester sandwiched between – accounts for more than 70% of the global backsheet market. However, since this figure was published in a previous article (Backsheets to the future – pv magazine 09/2018, p. 76) several industry experts have raised serious questions about the accuracy of this figure, and stated that it does not represent a realistic picture of the market for backsheet materials.

The German Mechanical Engineering Industry Association (VDMA), which publishes the ITRPV report chose not to comment on its estimates published in ITRPV 2018. Alternate figures from analysts at IHS Markit indicate that fluoropolymer materials in multiple combinations represent the vast majority of the overall market for backsheets.

“Generally, the polymer backsheet is classified in two main groups – fluoropolymers and non-fluoropolymers,” says Karl Melkonyan, Senior Analyst, Solar Technology at IHS Markit. “The share of fluoropolymer backsheet, those which comprise at least one layer of fluoride-based material, is estimated to account for 89% of the total market in 2018.”

As for the split between different fluoropolymer materials, data from IHS Markit show that backsheets consisting of at least one PVF layer represent around 40% of the market in 2018, with around 44% featuring at least one layer of PVDF. Melkonyan also notes that a very small fraction of the fluoropolymer segment is represented by backsheets produced using a coating method, where fluorine is applied as a protective coating to another material – PET, for example.

Materials giant DuPont, which produces PVF Tedlar film for backsheet manufacturers, says that it sees growing demand for backsheets containing PVF and PVDF layers. “Backsheets using Chinese made PVDF are gaining share due to competitive pricing, which is close to non-fluoro film-based backsheets such as PET, especially on a cost-per-watt basis as the drive for increased module efficiency continues. But the quality of Chinese made PVDF films varies a lot,” states Mark Ma, Global Marketing Manager at DuPont Photovoltaic Solutions. “Currently, most Chinese module makers use fluoro film-based backsheets.”

Material concerns

Fluoropolymer backsheets are favored by module manufacturers thanks to proven durability. DuPont also supplies its Tedlar films for a range of different industrial applications, and they show strong performance in accelerated testing.

And historically, the backsheet is often said to be responsible for more module failures in the field than any other component, leaving manufacturers and investors convinced of the need for highly durable materials. “Global field surveys conducted by DuPont have found more failures happening in the field with polyamide (PA) backsheets, PET, and PVDF backsheets, and it will cost module makers considerable amounts of money to replace the modules,” adds Ma. “At the same time, we are seeing downstream customers asking for a 35 or even 40 year lifetime to improve internal rate of return.”

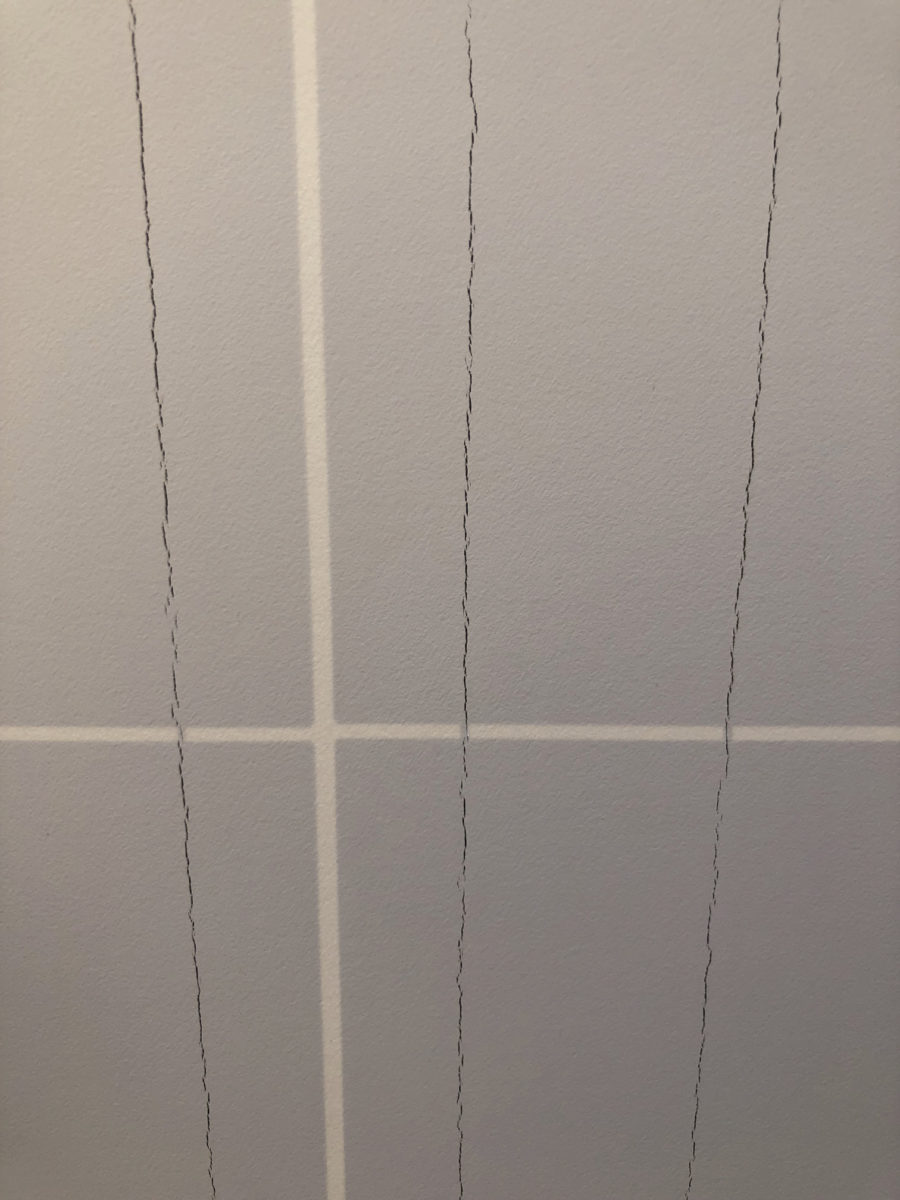

While it seems that established fluoropolymer-based backsheets will continue to represent the largest chunk of the market for the foreseeable future, there is considerable innovation happening with other materials. Polyolefins are viewed as having particularly strong potential, and Dutch materials specialist DSM has developed a co-extrusion process using such materials, to replace lamination – which is widely viewed as problematic due to the potential for multiple layers to become ‘unstuck.’

“We anticipate that cost effective co-extruded backsheets will gain market share over laminated backsheets,” says Imco Goudswaard, a business analyst at DSM Advanced Solar. “In particular co-extruded backsheets made of specifically engineered polymer compounds for the solar industry will become more and more popular, like our Endurance backsheet with a stable polyolefin (PET-free) core and fluorine-free sustainable outer layer.”

DuPont’s Mark Ma states that he sees the downstream market becoming more segmented, with a primarily price sensitive market on one hand, and a more quality driven segment which will insist on buying modules with the highest quality materials on the other. DSM though, says that its Endurance product can compete with PVF in the ‘high-end’ market: “Co-extruded backsheets do have a rather competitive performance versus mainstream and high-end fluoro-based laminated backsheet,” says Goudswaard. “The new generation of low-cost mono-layer backsheets will compete on cost with PET-PET laminated backsheets.”

Figures from IHS Markit forecast a modest loss of share for fluoropolymers, falling to around 77% in 2022, largely due to loss of share for PVF-based backsheet. “It is very difficult for a new material to gain acceptance in the market very fast, because it requires quality and reliability proven by tests, several years of field experience, and various certificates,” states IHS Markit’s Melkonyan. “However, the situation is likely to change gradually in the near future, as new technologies and components with increased performance are starting to gain share.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.