The US administration imposed a tariff on steel and aluminium imports last year to get companies to buy more American metal. In some ways, the duty has the US solar business doing the exact opposite as US companies have started buying completed racks from abroad in order to avoid the tariffs on raw material, according to Bloomberg.

For instance, PanelClaw, a Massachusetts-based supplier of steel racks that hold solar panels in place, has boosted sourcing of completed racks from India in order to skirt some of the duties that apply to raw metals only, Bloomberg reported.

While PanelClaw still acquires racks made domestically with American steel, the company can partly ‘avoid the tariff’ by importing the rest, CEO Constantino Nicolaou was quoted as saying in the report.

California-based Nuance Energy, another solar-racking company, has also boosted overseas sourcing, including from China, Malaysia and Mexico, since the steel tariffs were imposed. Increasing overseas sourcing further is ‘on the table’ if tariffs rise, CEO Brian Boguess told Bloomberg.

The unintended fallout

Steel prices for US buyers rose about 14% last year after Trump, contending that foreign metal threatened US national security, slapped tariffs on all steel imports. Tariffs raise the price of imports to make them on par with domestic goods, Bloomberg reported.

Unlike other commodities, steel is priced regionally. So American steel costs about 44% more than Chinese steel and about 31% more than European steel, meaning US metal is the most expensive in the world right now for consumers. The key reason was tariffs, it said while adding that the obscure trade law applied only to raw steel, leaving value-added products of the metal, such as solar parts, shielded from the tax.

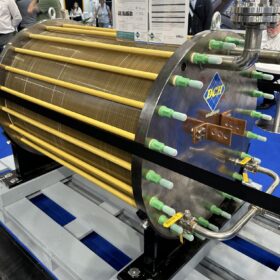

Among solar companies, the pain of the tariffs has been especially acute for racking companies that source the equipment needed to affix solar panels to the ground or atop roofs.

Steel is prominent in racking, so companies that can build such systems with less of it could be favored if the tariff endures.

US solar farm developers are also feeling the pinch. The tariffs can add one or two cents per watt to project costs, which could mean up to $1.5 million more to develop a 75MW project, developer Cypress Creek Renewables was quoted as saying by Bloomberg.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.