U.S. cadmium-free quantum dot and nanomaterials manufacturer Quantum Materials Corp has received an initial $500,000 (Rs3.4 crore) license fee from construction and electronics business Amtronics India.

Amtronics will use Quantum’s technology to develop, manufacture and commercialize of quantum dots through joint venture Qamronics India, formed by Amtronics and the state-owned Assam Electronics Development Corp Ltd (AMTRON).

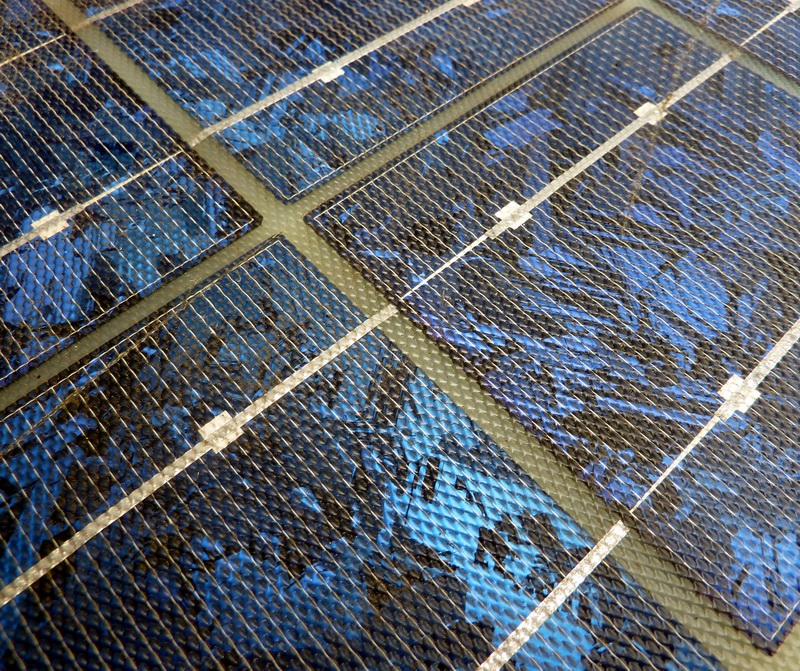

Construction has started on a 120,000 sq ft facility for large-scale, low-cost quantum dot production in Assam. The factory will also develop thin-film quantum dot solar cells, solid-state LED lighting and displays.

As part of the licensing deal, Amtronics will use the QDX trademark and technical data to support its marketing initiatives and Quantum will receive technology development funding, scheduled milestone payments and royalties on the quantum dots and solar cells produced.

The factory was initially conceived as a 12,000 sq ft fab but has been expanded tenfold and construction is expected to be completed by the end of the year.

Delayed by raised ambition

Stephen B. Squires, president and CEO of Quantum Materials Corp said: “The delay in processing of the upfront license fee was largely an unintended consequence of expanding the project scope from the initial $20 million to the now proposed $70 million. With this payment now in place, we are ready to move aggressively forward on this exciting new venture with our license partners Amtronics CC and AMTRON to bring the incredible power of quantum dots and the products they can make better to the India marketplace.

“While this project envisions both display and solid-state lighting products, the initial focus of this venture is for the establishment of domestically produced thin-film, quantum dot-based solar panels.”

“The Indian government has made a priority of putting in place multi-hundred-gigawatt levels of renewable energy sources by the year 2025, of which a large percentage of that power generation is slated to be provided by solar. We believe that thin-film quantum dot solar is the best candidate for filling this mandated initiative, due to its low capex and opex cost when compared to traditional PV/silicon based solar, especially given the fact that India has placed a huge premium on domestically sourced goods as part of [its] Make in India program, to promote domestic industries.

Production equipment order expected

“To that end we have laid out a very comprehensive roadmap to providing this solution with a now completed solar cell design with commercially economic power yield levels, along with fixed component quantum dot chemistry, and [we] plan to commence production of solar cells via a continuous, rapid-feed, flexographic-based printing process as soon as the manufacturing facility in Assam is up and running.

“Now that we have received this initial funding, the next step is providing two large-scale quantum dot reactors to establish quantum dot production at the India facility to support the solar cell print line. We expect to receive a purchase order for this equipment in the next few weeks along with an 80% upfront payment. You can expect a series of announcements regarding this venture over the next six to 12 months, in the form of interim updates.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.