Scientists at the University of Bath’s center for sustainable chemical technologies are planning to use perovskite-based solar cells for the production of hydrogen.

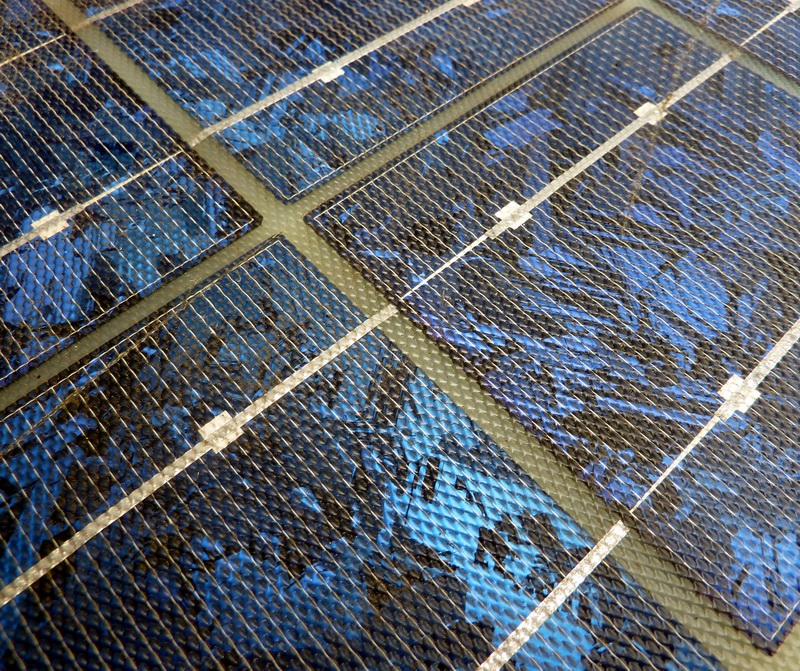

In the Graphite-protected CsPbBr3 perovskite photoanodes functionalised with water oxidation catalyst for oxygen evolution in water report, published in Nature Communications, the research team claims to have developed a waterproof cell that functions underwater by splitting water into hydrogen and oxygen using electrolysis. The U.K. university’s researchers are now trying to address the issue of perovskite instability underwater by applying a graphite coating to the material layer.

“The coated cells worked underwater for 30 hours – ten hours longer than the previous record,” the scientists wrote, adding the glue sandwiching the coat to the cells began to fail after 30 hours. They believe stronger glue could help the cell stabilize for longer. “We achieve a record stability of 30h in aqueous electrolyte under constant simulated solar illumination, with currents above 2 mA cm−2(milliamperes per cm−2) at 1.23 VRHE,” they added.

Instead of costly indium, much cheaper and more sustainable commercially available graphite has been used to coat perovskite cells intended for electrolysis.

The researchers are also attempting to raise the voltage generated by perovskite cells to the level required to perform electrolysis without additional sources of power. “To solve this challenge, the team is adding catalysts to reduce the energy requirement needed to drive the reaction,” the report stated.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.