From pv magazine 04/2020

Whether ongoing progress with p-type PERC, a shift to n-type TOPCon, or a switch to heterojunction (HJT), high-efficiency PV cell production requires one thing: clean wafer surfaces and the minimizing of cross contamination in wet chemistry processes. This, at least, is the experience of Gerry Knoch, the PV industry veteran leading Germany-based exateq GmbH. And while larger wafer sizes may be the most talked about issue within cell production in 2020 thus far, he sees mixed payoffs in ever increasing sizes.

“I am not sure that all equipment can handle these larger wafers,” says Knoch, addressing this latest most-hyped industry trend. “With M6 (166mm2), only some older equipment can’t handle it. With M12 (210mm2) I’m confident that nothing can handle it.”

A battle of sorts is playing out at present in the PV cell production landscape – with wafer size representing the front line. Mono giant Longi is advocating for the M6 cell format, which it argues will result in lower LCOE. “166mm is the best size, because it delivers the lowest cost right now,” Longi founder and president Li Zhenguo told pv magazine earlier this year (pv magazine 03/2020). “To change the production line to 166mm you just have to adjust the line slightly. So, I think it will result in lower costs.”

On the other side of the size argument stands Zhonghuan Semiconductor, which was the first to reveal the 210mm, or M12, format in mid 2019. It has since been joined by cell makers Tongwei and Aiko Solar, which have revealed planned M12 production capacities of 10 GW and 5 GW, respectively.

Throughput losses

It may be somewhat of a fools’ errand to predict at this stage which wafer format will prevail in the long term, and there are reasons to believe there is as much competitive positioning as there is true technological development behind the drive to differing sizes. For exateq’s Knoch, he sees losses in wet bench throughput as canceling out any gains delivered by markedly larger wafer sizes.

“Larger wafers will certainly make a big difference in how you run the [wet bench] tool, but it is not necessarily more megawatts of throughout,” says Knoch. Larger wafers can stick together after processing, resulting in reduced yield, he explains. To counter this, cell carriers with a larger gap, or pitch, between each individual wafer can be used, but here again tool throughput goes down.

“Larger wafers always cause a little pain, but in the end people manage. 166mm okay, but 210 M12 is a totally different kettle of fish. The tanks must be tremendously bigger, much larger volumes of the chemicals … it is all doable, but I don’t know whether there are benefits in production.”

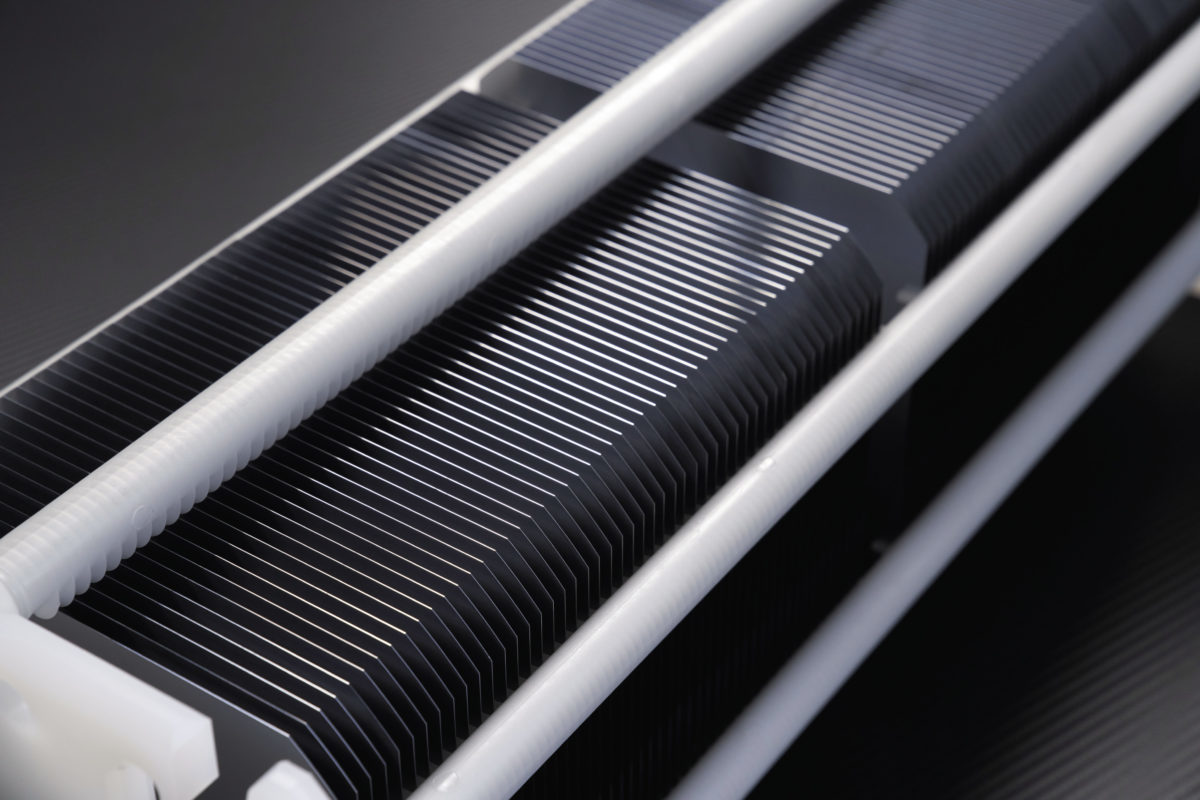

Knoch says an additional challenge with the larger sizes is process quality due to carry-over of chemicals from one bath to the next. A hold-down device, or retaining bar, is required over the top of the cell carrier to prevent wafers from floating out of the carriers, borne by gases created in various chemical baths. Such a retaining bar can have crevices on it, where it attaches to the carrier, that may not fully drain, resulting in cross contamination between the baths, called carry-over. This may influence the various process steps and particularly the drying.

With the former smaller cell sizes there was a way around the retaining bar which no longer works for the new larger cells. In short, the larger the wafers, the higher the floating force that can mean the whole carrier floats, requiring new measures to keep the carrier submerged.

Cross contamination

“Any cross contamination is a big issue,” says Knoch, noting that this is particularly the case in high-efficiency processes that are sensitive to the cell surface. Drag out can also be referred to as carry over, and unless it can be minimized it can impact on process quality. “Recently I heard from two sources they have issues with their carriers in the high efficiency range.”

To address the potential for cross contamination from chemical drag out and to provide finely tuned wet chemical solutions, exateq has taken over the carrier business from acp Systems. The carrier company, perhaps more widely known under its former name of ACI Ecotec, has been a supplier of carrier systems for solar cell wet chemical processing for close to two decades.

Having signed the deal to take over the acp Systems’ carrier business in late 2019, exateq now has the control over the carrier suppliers’ portfolio, including its patents, and will handle any ongoing business. Importantly, it can also develop carrier solutions hand-in-hand with its wet benches, and according to precise customer requests.

“Having your own carrier production can be quite helpful as you can control quality and work on solutions for new trends, says Knoch. “That is all in our hands now and can match that with our wet bench.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.