From pv magazine 08/2020

Lithium-ion batteries have already transformed modern technology, and in powering electric vehicles, balancing renewables led grids and much more, their importance is only set to increase. But the technology is not without drawbacks.

Top of the list is safety. Though generally safe enough for everyone to carry one around in their pocket, several high-profile cases where batteries have caused fires demonstrate that the technology still carries an inherent risk. Second is performance, as new applications demand ever more energy, less weight, and lower cost. And squeezing more out of the current approach is becoming increasingly difficult. Solid-state batteries represent one approach that could remove the safety concerns entirely, and open a lot of doors to further improvements in performance.

Lithium-ion batteries typically comprise a graphite anode, a nickel-manganese-cobalt cathode, and an electrolyte of lithium salt dissolved in an organic solvent. The electrolyte is cause for much concern. “Liquid electrolytes are very flammable and tend to be the main initiators of thermal runaway. This is the main safety hazard in lithium-ion,” says Josh Buettner-Garrett, chief technology officer at Solid Power, a U.S.-based developer of solid-state technology. “Lithium-ion batteries today are very safe, but that comes from an oversized and overdesigned pack, which adds cost.”

Switching the liquid for a solid material offers an instant benefit in eliminating a hazardous material. This, combined with the fact that there is no liquid or gel substance to manage, allows product developers to reduce the amount of packaging and other energy-redundant materials, improving the energy-to-weight ratio.

Step change

The real advantage, though, is in enabling new materials. There is a whole host of electrode materials that are not stable in a liquid electrolyte, but warrant a second look in an all-solid-state battery, and this will be a whole new chapter of research into lithium-ion batteries. In the nearer term, though, a solid-state battery enables the use of a lithium metal anode, which has around 10 times the specific capacity of the graphite anodes used in conventional lithium batteries.

Lithium metal is generally considered too unstable to function with a liquid electrolyte. The way ions collect at the anode leads to the formation of dendrites – branch-like structures that grow from the anode’s surface. These cause rapid degradation of the battery, and can lead to short circuits and fires if left unchecked.

With a solid electrolyte, the risk of dendrites is greatly reduced because the way lithium-ions move through a solid electrolyte is fundamentally different, and the Li-metal – electrolyte interface is more stable than with a liquid electrolyte. “It’s really about controlling the actual lithium electroplating and stripping behavior at the chemical level, says Buettner-Garrett. “What’s important is getting the lithium to deposit in a uniform way, as opposed to producing in small pockets that are then hotspots for the formation of dendrites.”

This uniform deposition brings the further benefit of reduced, or even eliminated, performance loss. Conventional lithium-ion batteries can lose as much as 2% of their capacity per year, amounting to 20% over a product’s 10-year warranty lifetime. Developers of solid-state technology claim these batteries can maintain 100% of their initial capacity, and that eventually devices will be engineered with a much longer lifetime.

Key challenges

The first step to realizing these advantages is a stable, solid electrolyte. Logically, it might seem the challenge here comes down to simple physics – that it is more difficult for ions to move through a solid than through a liquid. And while this assumption guided much earlier research into SSBs, the reality is somewhat more complicated. “In some cases, solid electrolytes have been developed that are actually more conductive than the liquids,” explains Buettner Garrett. “The challenge really comes at the interfaces. Once an ion leaves one solid particle and enters another, between particles within a given layer, and going from layer to layer, those are typically your bottlenecks.”

The materials on which research tends to focus are broadly divided into three classes: polymers, oxides, and sulfides. However, new material concepts – including halides, ceramics and the glass battery patented by the Nobel Prize-winning inventor of the original Li-ion battery, John Goodenough – are also gaining ground in the research community.

The focus for most of the large battery players, including Samsung and LG Chem, is on sulfide electrolytes. “Sulfides are scalable, you can process them at room temperature, and you can bring them to commercial form factors,” says Darren Tan, a scientist in University of California, San Diego (UCSD)’s Department of Nanoengineering. “Oxides are more brittle and require much higher sintering temperatures, while polymers have long struggled with conductivity at room temperature.”

Like UCSD, Colorado’s Solid Power is focused on sulfide electrolytes. “We believe sulfides have the most well-rounded set of characteristics,” says Buettner-Garrett. “Most of the OEMs and the carmakers are focused on sulfides at this point. Many are looking at polymers as an initial entry into solid-state, while most of the oxides today are limited to academia.”

Scaling up

Another challenge is developing processes that can bring the technology out of the lab and into production. Here, polymers have an advantage. “There is no solid electrolyte that meets all of the ideal requirements. The advantage with polymers is scalability, we can go to large formats and roll to roll processing,” explains Chisu Kim, a researcher at Canada’s Hydro Québec. “The problem is low conductivity at room temperature.”

Here it should be noted that in one form, solid-state batteries have already been in production since 2011. French company Blue Solutions, a part of the Bolloré Group, operates 500 MWh of production capacity for its lithium metal polymer (LMP) battery, an all-solid-state product based on a polymer electrolyte.

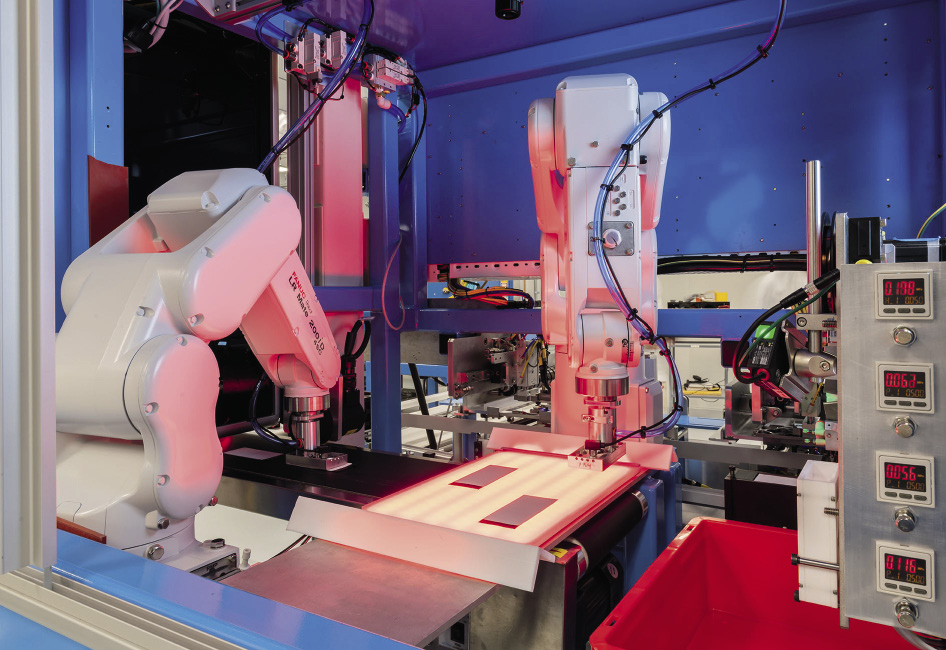

Bolloré Group has a wealth of experience producing thin films, which it puts to good use in battery production. “You have rolls of very thin material that flow up and down and are stacked together,” says Francisco da Silva Passos, business development manager at Blue Solutions, describing the production facilities. “Everything is automated, it produces a sandwich of thin films and that is the battery.”

The LMP battery comprises a lithium metal foil anode, solid polymer electrolyte, and lithiated iron phosphate cathode, supported by an aluminum current collector. Blue Solutions has deployed the battery in vehicles for car-sharing and commercial use, as well as remote solar minigrid projects. According to its developers, it offers many of the advantages solid-state researchers are looking for. “It is physically impossible for our battery to ignite itself. The only way to burn this battery is to put it in a fire and let it burn,” says da Silva Passos. “Secondly, performance is guaranteed at any temperature.”

He goes on to explain that the temperature properties are key, as conventional Li-ion batteries are highly sensitive to temperature, and often shipped in refrigerated, temperature monitored containers. “If there is a problem and the temperature reaches say 30 degrees, this will impact the guarantees,”

It is also temperature, however, that limits use cases for the LMP battery. The electrolyte needs a temperature of around 80 C to be conductive. In practice, this means regular deep cycling is needed to maintain performance. Da Silva Passos explains that, for a bus or commercial vehicle, this is not a problem, as the use case means it is regularly driving all day, discharging most of the battery. But for a private car whose owner is only doing 10 or 20 km a day, LMP is not a good fit. “Our battery is well suited to intensive use,” says da Silva Passos. “With at least several cycles a week you can keep the heat stable without any additional systems.”

The LMP has only a slender advantage in energy density, partly due to the need for additional insulation materials. Blue Solutions says the battery maintains 100% of its capacity over its lifetime, and currently, it usually supplies batteries with a 10-year warranty, though it believes the batteries can have a much longer lifetime and is gathering data for a possible extension, as well as working on a battery that runs at lower temperature.

Next generation

The real step change will come with the development of a processible solid electrolyte that performs at room temperature. Here the development of suitable materials, as well as the large scale processes themselves, is still a roadblock. This is where industry begins to take over from academic research. “There is a lot of science coming out, and we are leaving it to industry to take the science and work on scalability,” says UCSD’s Darren Tan. “Most of the major hurdles now are engineering rather than solid battery science.”

As an example, Tan notes that with solid-state batteries reported in academic literature, electrolyte films are typically around 1mm thick, but would need to go down to less than 0.05 mm to be industrially scalable. “Scientists are trying to emulate existing Li-ion processes so that the technology can be a drop-in solution,” says Tan. “If you go down a completely new pathway, it’s going to take another 20 to 30 years to build new machinery.”

Tan further notes that lithium metal presents another set of challenges here as a material that’s often difficult to work with. In the laboratory setting, solid-state batteries are often prepared in an inert environment, with no moisture or oxygen. This adds another layer of complexity, and potential cost. Zooming out further reveals yet more challenges at the market and supply chain level, as many of the materials that go into a solid-state battery lack a developed supply chain, and there is currently no demand that would lead to one developing.

Solid Power’s approach is to work with partners up and down the supply chain, ensuring these segments to some degree are able to develop in unison. On the battery/vehicle side the company has partnerships with BMW, Ford, and several other car manufacturers, as well as players in aerospace and consumer electronics. And further up the chain, it is working closely with Tier-1 battery cell makers and with the materials companies that produce the base ‘ingredients’ for its battery components. The result of this, says Buettner-Garrett, is that already the company can already produce prototype solid-state battery cells on equipment that’s in use at existing lithium-ion cell factories.

It is expected that the first solid-state batteries, and the vehicles that run on them, will begin to roll off production lines within the current decade. “Right now, OEMs are targeting anywhere from 2025-30 for true production vehicles, with concept vehicles containing solid-state batteries unveiled over the next couple of years,” says Buettner-Garrett. “And you have other markets – medical, aerospace, which will happen earlier, likely before 2023.”

But while the technology may already be on the brink, other factors mean it could be a long while before solid-state batteries are seen as a true replacement for conventional lithium-ion. “Sure, they can demonstrate prototypes and pilot scale. But to make the jump into-full scale manufacturing is a multi-billion dollar investment,” says Tan. “Deeper market penetration really depends on the economic situation and whether governments are ready to set policies to promote it.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

The fundamental concept of trying to store huge/masdive numbers of extremly light charged particles (electrons/protons) in an electrolyte that probably weighs a trillion times more than the charged particles involved, is flawed.

Why did we choose this…. because someone discovered this “phenomenon” about 200+ years back. (Earlier efforts will have to be ignored as the “world of electricity” was not known or discovered then).

For a true “grounds up” solution…. we have to calculate the number, weight, volume, force etc… of the chatged particles (electrons and protons) we are trying to store….. and then using ALL our understanding of the forces of nature (aka Science) figure out a solution…. Materials, Mechanical, Chemical, Electrochemical, Electrical/Electronic etc….

We all understand this is an “electrical problem” but have jumped on the (Electro)Chemical bandwagon of Batteries. Capacitors were created to “store electrons” but have failed to store large amounts of it with minimal mass too.

What one needs is some sort of a electro or magneto “black hole” that can store and contain these charged particles with minimal weight….

Perhaps a Energy Storage Mass Ratio (Weight of Storage/Weight of Charged Particles) criteria….. say of 100 ….. would be a good starting point….

as said earlier…. we have to re-think this whole “Way of Storing” Charged Particles… from the ground up…