The progress seen in India, like in the case of solar PV deployment with public-private partnerships and policy support, will be required for hydrogen as well, according to a recent report published by the Department of Science and Technology.

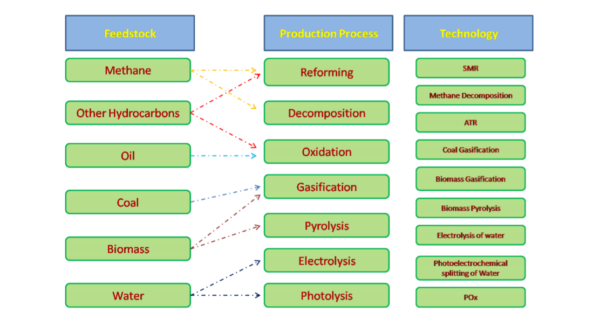

The India Status Report on Hydrogen and Fuel Cells states hydrogen—as a non-polluting, efficient and clean energy carrier—can reduce India’s dependence on oil and gas imports. It is abundant and could be produced from a wide variety of locally available primary or secondary energy sources using an appropriate production route.

Further, hydrogen can be used for small- to large-scale and short- to long-term storage to meet seasonal or daily supply-demand imbalance with renewables deployment.

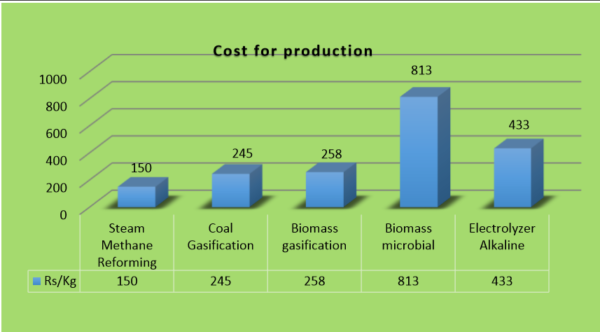

The report notes that clean hydrogen technologies are available in India. However, the nation needs to address challenges to scaling up, cost reduction, increased adoption, and sustainable growth of hydrogen-based technologies.

At present, hydrogen is at an early stage of penetration in the energy sector.

The report suggests introducing hydrogen into the existing, proven set of applications with a more diverse set of energy sources of its production and then moving on to green hydrogen or introducing it to the new set of applications. The transition pathways that use existing infrastructure and skills—for example, blended natural gas with hydrogen—will be economically feasible and easier to adapt.

“In the short term, hydrogen can be introduced in various sectors with technologies deployed irrespective of whether it is blue, green or grey hydrogen. In the inter-intermediate term, the blending of gas with hydrogen could be a possible method to reduce emissions. Simultaneously, making hydrogen a part of a large-scale distribution network, increased green hydrogen usage should be introduced. In the long term, the entire hydrogen value chain should be completely emission free”—recommends the report.

Meanwhile, the government needs to create a long-term policy framework that could build up confidence in private investment, create market demand with policy interventions, develop standards and regulations which should not hurdle the growth, and provide enhanced R&D support.

Current production and use

The report states that hydrogen is produced in India mostly as a byproduct of either the refinery processes or chlor-alkali plants. Some limited hydrogen is also produced through electrolysis for commercial use.

However, most of it is internally used for various processes, and very little quantity is available for utilization for other applications.

There were around 40 Chlor-alkali units in 2013-14, producing 66,000 tonnes of byproduct hydrogen, out of which 6600 tonnes was not utilized.

The report notes that hydrogen will see a significant rise in demand in the end-user industry. With stringent environmental regulations, its demand will increase in both the transport and power generation sectors.

Research in mission mode

Many funding agencies in India, both government and private, support R&D projects on different aspects of the hydrogen economy, including hydrogen production, storage and utilization for stationary, power generation, and transport applications (using either IC engines or fuel cell technologies).

The Hydrogen and Fuel Cell program by the DST aims to develop transformational technologies that reduce hydrogen production cost, distribution and storage, diversify the feedstock available for economic hydrogen production, and enhance the power grid’s flexibility, and reduce emissions through novel uses of low-cost hydrogen.

Thus far, the program has supported 30 research projects.

Greener methods of hydrogen production—electrolysis via chemical or photo-electrochemical routes—are also being explored in India. The research is being carried out from materials to system level.

Here, DST activities are mainly focused on more efficient reforming processes and development of newer membranes, and improving the efficiency of water-splitting reaction. Development of cost-efficient and earth-abundant catalyst for photo-electrochemical water splitting, newer materials, catalysts and electrodes to accelerate the reaction and Sorption-enhanced reforming for improved hydrogen production from biogas is underway.

Considerable success has been achieved in technology development. For instance, in alkaline water electrolysis, the technology from Bhabha Atomic Research Centre (BARC), Mumbai, is available for commercialization.

At BARC, extensive research is also underway for other hydrogen production technologies like hybrid-sulphur process, Cu-Cl process, and proton-exchange-membrane (PEM) based water electrolysis.

The Central Electro Chemical Research Institute under the Council of Scientific and Industrial Research (CSIR-CECRI), Karaikudi has explored the design of electrodes and electrolytes for hydrogen generation using seawater, with reduced Titania as a catalyst.

ONGC Energy Centre (OEC) is investigating thermochemical water splitting for large-scale hydrogen generation.

A multi-institutional research project supported by the Technology Systems Development Program of DST, New Delhi, aims to develop scalable solar hydrogen generation systems using multiple technologies. The project participants include the Indian Institute of Technology (IIT) Kanpur, IIT Madras, Dayalbagh Educational Institute Agra, IIT Jodhpur, CECRI, Karaikudi, and BARC Mumbai.

In terms of end-use applications, the Ministry of Non-Conventional Energy Sources has supported many demonstration projects through Indian Oil Corporation and Society of Indian Automobile Manufacturers.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

It is gettimg increasingly clear that the polluting fossil industry will simply NOT GO AWAY… without a fight and keep sending millions to their pre-mature Death and make many many more suffer too.

If Hydrogen can be produced from Clean, Green, Sustainable and Abundant Solar Energy to AV/PV to Elecyrolysers…. why does the world need Trojan Horse Solutions …. these “Trojan Horses” hide behind a deveptove “skin” of environmental friendliness. In fact they are just surrepetious Trojan Horses…. as I said the self-righteous Polluters of the last 200 years having caused the pre-mature death of hundreds of Millions and Billions of Years of Suffering…. will just not accept that THE PEOPLE have had enough and look for a future based only on Solar Energy…. I say… let Fossil/Nuclear RIP…. every Day of Delay causes … unneeded 25,000 deaths daily as millions suffer…

THIS IS WHAT IT IS ALL ABOUT…. BUT THESE POLLUTERS JUST 🙈🙉🙊🙈🙉🙊