From pv magazine International

Balancing the cost of a cleaning cycle against the revenue lost from dust and dirt soiling a PV panel is often a difficult equation for PV plant operators, one that’s as unpredictable as the weather. Getting it wrong either way can lead to a significant loss of revenue, so there is plenty of interest in the topic and the development of models to predict the effects of soiling and calculate an optimal schedule for module cleaning.

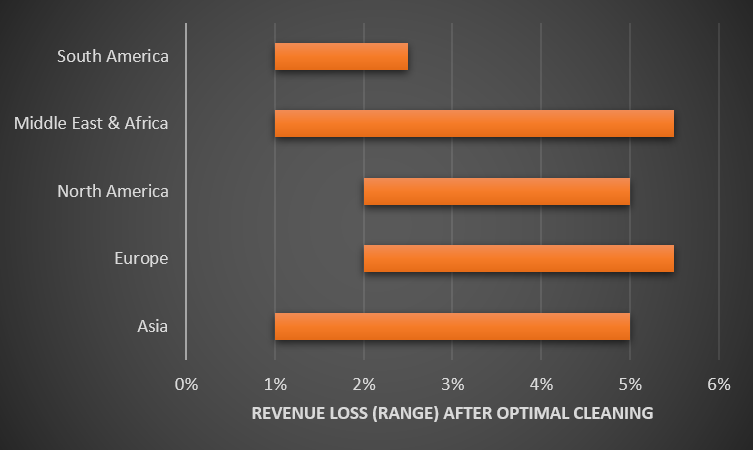

While the soiling profile can vary greatly even between two sites in the same region, there is value in looking at regional data. Scientists led by East West University in Bangladesh analyzed soiling trends in different regions, aiming to provide a global overview of the effects of soiling in different parts of the world, and to develop a model to calculate the best cleaning cycle to optimize project revenue.

The model is described in the paper Global analysis of optimal cleaning cycle and profit of soiling affected solar panels, published in Applied Energy. In their analysis the scientists assumed a project size (yield under 1-sun) of 100 MW, a cost per cleaning operation of US$2670, which it notes is at the lower end of cost estimates for cleaning, and an electricity tariff for the project of US$0.069/kWh – though they note that cleaning costs can be much higher in certain regions, which will affect optimal cycle calculation.

The group was able to show that based on studies of two solar plants located in Saudi Arabia and Chile, calculations from their model fell within 0.1% of the actual numbers, demonstrating the model’s validity to PV project investors.

The study also concluded that there is little value in seasonal variations to cleaning schedules, with only negligible increases in revenue resulting from such optimization. For regions prone to sandstorms, the modeling becomes much more complicated, and the researchers warn that investors should carefully consider the viability of projects in such regions.

And a global level, the model finds the worst soiling conditions in Asia and the Middle East, where even with optimal cleaning schedules implemented – usually every 5-6 days – soiling losses still amount to around 2.5%. In Europe and North America, a cleaning schedule every 10-12 days is enough to limit soiling losses to below 1.5%.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.