From pv magazine 03/2021

In light of the current hype surrounding the global hydrogen economy, the words of French writer Jules Verne, written in 1875, verge on prophecy. “I believe that water will one day be employed as fuel, that hydrogen and oxygen which constitute it, used singly or together, will furnish an inexhaustible source of heat and light, of an intensity of which coal is not capable.”

Today, thanks largely to the precipitous decline in the cost of wind and solar energy, green hydrogen is finally approaching commercial reality. But it is the practicality of transporting this inexhaustible fuel that we must face in our time. And how regions rich in renewables will transport green hydrogen to energy-hungry markets like Europe and Asia is yet to become clear.

In some cases, the most economically obvious solution seems the repurposing of existing gas pipelines, but for others, the great distances demand a different solution, such as hydrogen shipped in the form of green ammonia. But questions remain as to whether hydrogen can be effectively transported in existing pipelines, and whether green ammonia is all that it’s cracked up to be.

Global pipelines

In 2017, British-Dutch oil giant Shell published the HyARC Hydrogen Study. It found there is at present 4,500 km of hydrogen pipelines globally – a good start, but insufficient to see a wholescale adoption of the new fuel. Existing gas pipelines can be repurposed, according to Dolf Gielen, the director of innovation and technology at the International Renewable Energy Agency (IRENA). He notes that hydrogen has already been used in such pipelines, in some cases for decades.

This is not to say that all existing steel pipelines can transport 100% green hydrogen. Indeed, with only a few exceptions, hydrogen in existing gas pipelines exists in a minority relationship to natural gas. However, as a 12 km section of the Gasunie pipeline from Dow Benelux to Yara in the Netherlands proves, an existing main gas transport pipeline can be modified for 100% hydrogen transport. That pipeline has been transporting more than 4 kilotons of hydrogen to a chemical plant since 2018.

Existing infrastructure does need some modifications if it is going to carry 100% hydrogen. “For instance,” says IRENA’s Gielen, “anything that is plastic needs adjustment, so the flanges need replacement, and you need to work on the compressors, you need more compression power because the molecule is smaller and requires more compression effort.”

According to the European Hydrogen Backbone Report, 75% of the pipelines in Europe are already able to carry varying quantities of hydrogen. Those pipelines unsuited to hydrogen tend to be at the end of their regulatory life, so in general it may be said that almost all modern, well-built and serviced pipelines, provided they are not already operating at peak, have hydrogen-carrying capability.

Potential threats

Nevertheless, there remains persistent mention of the possibility of hydrogen embrittling pipelines. However, Barbara Jinks, a manager of IRENA’s Green Gas Delivery and Use program, notes that the danger of embrittlement posed by hydrogen is only to exacerbate the problem of a pipeline already in a state of disrepair. If the pipeline has a crack in it, then hydrogen in large quantities can cause a chemical reaction that works to embrittle steel. Although, Jinks notes that if pipelines “are designed and constructed to international codes and standards then that minimizes the risks of cracks in the first place.”

There has also been talk, indeed from no meaner source than Nobel laureate and the 12th U.S. secretary of energy, Steven Chu, of a potential polymer modification which can be added to existing pipelines to make them hydrogen safe. However, Jinks says that despite a lot of talk since it was proposed by a French team in 2020, “there is no scientific basis for it and they withdrew it as an option.” Such a solution might be applicable to pipelines not suitable for hydrogen at all, but since such a large percentage of existing infrastructure, at least in Europe, is usable, such an application is “absolutely unnecessary for modern-built pipelines … because they can take hydrogen.”

In the U.S. context, perhaps Chu recognizes wider application for the polymer solution. But as Gielen was quick to note, “the discussion in the U.S. is very different from the European discussion … there could be benefit in some more international dialogue on this.”

In addition to Gielen, Jinks, and the European Backbone, natural gas companies have been doing their own studies. According to Massimo Derchi, chief industrial assets officer at Italian gas giant Snam, more than 70% of Snam’s pipelines are suitable for hydrogen. “The relatively modest part of the network which is not compliant has on average already exceeded the regulatory life,” he said. “Compression stations shall be partially modified and the feasibility of hydrogen injection into our underground storage sites requires additional studies and tests, but the suitability of the underground pipelines is a key advantage.”

Weighty issue

Next to transport, storing hydrogen is another great challenge. Hydrogen is often referred to as having great energy density, but this density is found in its weight (per kilogram), not in its volume (per cubic meter), and volume is the real concern when it comes to hydrogen storage.

Martin Tengler, lead hydrogen analyst at BloombergNEF, says compressed hydrogen requires 3.8 times the volume of storage space as natural gas (per unit of energy stored). This is part of the problem of transport, too. After all, to transport the same amount of energy as natural gas, you’d need more ships and trucks. Even when liquified, which is already an expensive process, requiring cooling to -253 C, hydrogen requires 2.5 times the volume of LNG – meaning you’d need more than double the number of hydrogen tankers for every LNG equivalent.

Ultimately, transporting hydrogen via pipelines is not a pipe dream, but nor is it a cure-all. Just because it can be transported in existing infrastructure does not mean that it is the best transition fuel for all applications. Gielen reminds us that it is IRENA’s position “that wherever you can directly electrify is better than using renewable energy to create hydrogen and then to transport the hydrogen.” For instance, it makes more sense, and is cheaper and far more efficient, to electrify home appliances used for cooking and heating, rather than refit millions of homes with boilers capable of withstanding variable gases.

Pipelines, then, are the cheapest and best way of transporting hydrogen – at least, transporting it regionally in what are called micro-networks. Like natural gas, transregional networks might also transport hydrogen. However, over a certain distance, pipelines simply lose their feasibility. What then?

Green ammonia

Transporting green hydrogen produced via solar and wind in North Africa to Europe through existing pipelines, or even via new infrastructure, is a no-brainer. But as soon as you start talking about transporting hydrogen from, say, Australia to Japan, nobody with a brain would suggest a pipeline. As Tengler put it, “the difference between pipeline and anything else is massive.” Transportation over such large distances requires a different solution, and one such solution already being shipped around the world is ammonia.

A country keenly looking to ship green hydrogen in the form of ammonia is Saudi Arabia, which has planned a futuristic city on the Red Sea, called Neom City, to be exclusively powered by renewable energy. The plan is to utilize this enormous renewable output to generate hydrogen and convert it into green ammonia for export – 1.2 million tons of it annually. As Gielen sets out, the plan is for destination markets to reconvert the ammonia back into hydrogen.

One impediment to such plans is that the conversion of hydrogen is expensive, and its reconversion even more so. Whether hydrogen will be competitive after reconversion depends on the destination country. But thankfully, the advantage of shipping ammonia is that the country could still use it directly for fertilizer and even for power generation without reconversion, though it should be added that ammonia, unlike hydrogen, is a toxic gas.

“The Japanese want to use green ammonia in coal-fired power plants,” says Tengler. “Eventually they want to do 100% ammonia … for a place like Japan importing hydrogen in the form of ammonia and using it directly could make sense in some instances.” Saudi Arabia has already trialed a shipment of blue ammonia to Japan. Going forward, for resource-rich countries like Saudi Arabia and Australia, shipping green ammonia may be the most feasible way “to sell their hydrogen.” As Cosma Panzacchi, the executive vice president of Snam’s Business Hydrogen Unit, puts it: “Green ammonia can play a very important role for hydrogen transport from countries that have a big potential in terms of production, but they are not connected through a pipeline. The transport via ammonia could integrate the pipeline transport for long distances, similarly to LNG for natural gas.”

Moreover, Gielen points out that when it comes to green ammonia, “it is not only a question of how do you ship ammonia, but ammonia for shipping … That’s the idea, to directly use it in a ship engine.” Whether or not the economics of such a development are feasible, it is technically feasible.

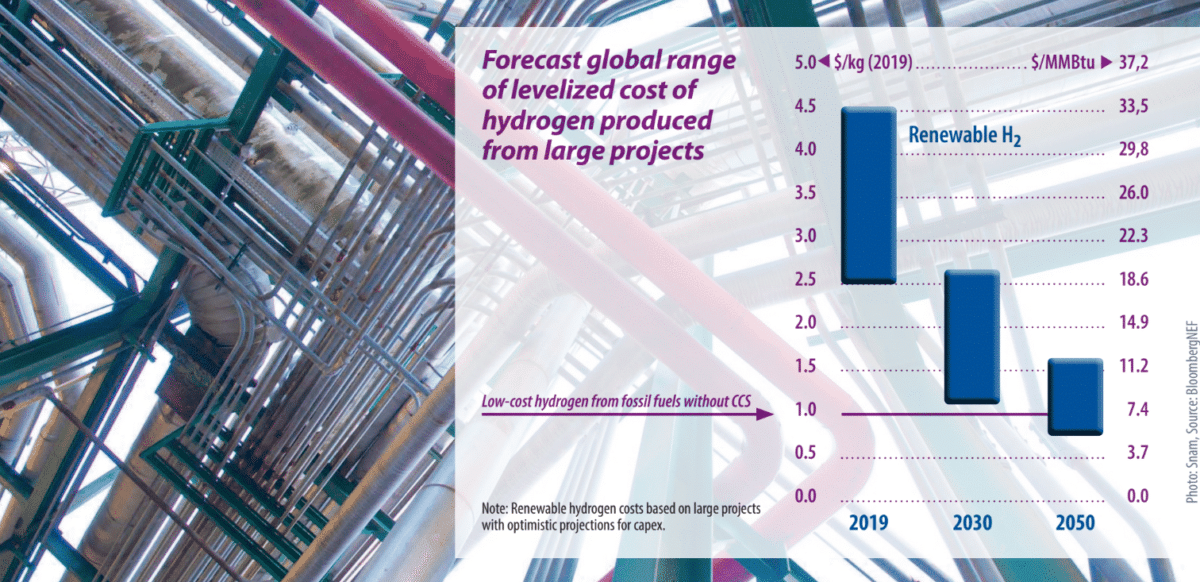

As it stands, we have solutions to the challenge of green hydrogen transportation. There are other transportation options available, but all are still in early phases of testing and development. Thankfully, as Tengler’s calculations show, “if you break down the levelized cost of hydrogen production, renewable electricity makes up a larger proportion and it’s going to make up an even larger proportion as the cost of electrolyzers go down too. So, I would say potentially the most important breakthrough in the cost of hydrogen is not in production or transport technology, but rather the continuing decline in the cost of renewables.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.