From pv magazine 07/2021

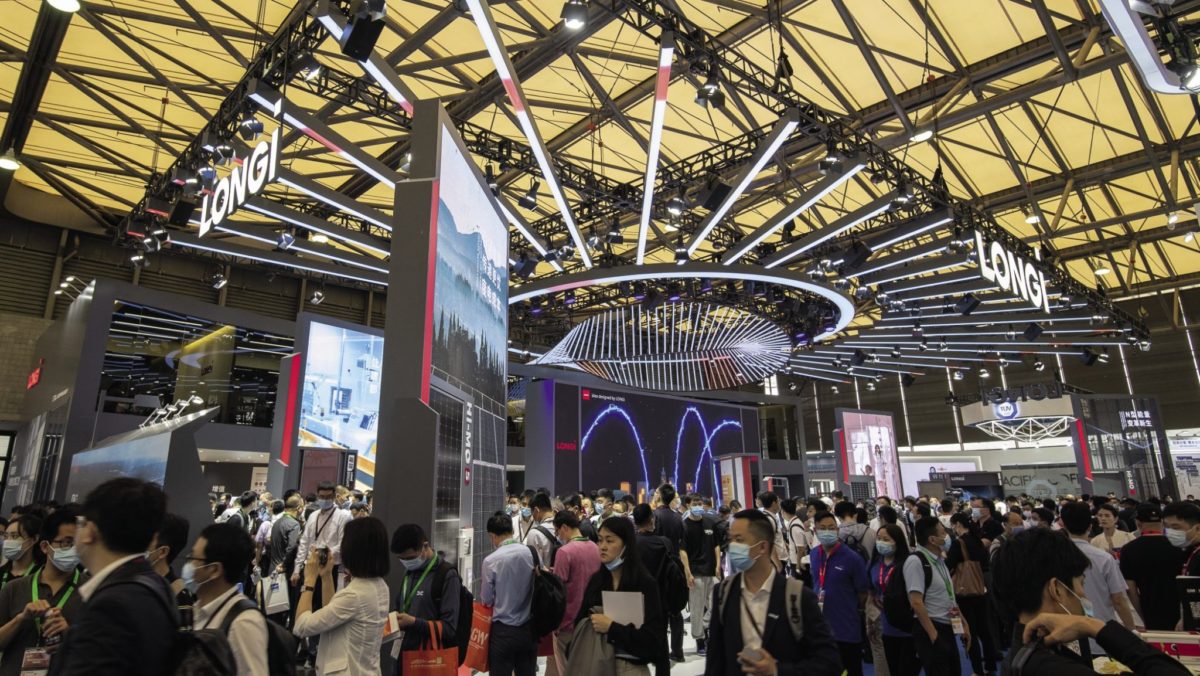

With a record of around 2,000 participating enterprises and more than 220,000 visitors, the SNEC 2021 show was held in Shanghai in the first week of June. On the show floor, pv magazine discovered n-type, BIPV, and solar+storage to be pervasive technology and application trends.

For a long period, major Chinese cell and module makers have invested in n-type crystalline silicon cell technology, which promises higher efficiencies than can be achieved with p-type PERC, and the next step on the solar technology pathway. However, pressured by high costs and technical difficulties, most n-type products from the major Chinese manufacturers have remained at the laboratory or pilot line stage.

N-type time

In 2021, however, most major PV panel manufacturers launched n-type products – and this was clearly evident at the trade show. Longi, for example, introduced its Hi-Mo N panel based on N-TOPCon technology. Jinko launched its Tiger Pro N panel – also based on TOPCon.

Not all developments were TOPCon, though. Sunport introduced its C10 Pro based on HJT, while Canadian Solar and Risen also launched new HJT products. Trina Solar, Tongwei and JA Solar revealed new high-powered panels, based on both TOPCon and HJT cells. Other Tier-2 manufacturers like Haitai, Akcome, Jolywood, and Jinneng all launched new PV panels based on either TOPCon or HJT.

There are now more than a dozen top Chinese PV module manufacturers making a real move into the next generation of n-type PV products. And the sentiment at SNEC was that more companies will soon be making the shift. The only difference in terms of technology strategy is that some of them are sticking to a single track, either TOPCon or HJT, while others are hedging their bets.

Higher power

At SNEC 2021, most module makers presented products based on either 182 mm or 210 mm wafers. This means both larger modules, and much higher power ratings. The typical 182 mm PERC module comes with an output of 520 W to 600 W, in 72- and 78-piece formats. For those based on 210 mm, typical power outputs lie between 540 W and 620 W – a small difference from 182 mm types. Only one giant large-format module from JA Solar provides power up to 800 W. Panels based on n-type TOPCon or HJT technology and 182/210 mm wafer did offer even higher base power, up to 700 W, with the same size as PERC type.

In terms of module formats and cell configurations, most leading module makers utilized multiple technologies. They included various approaches to reduce the gaps between cells, laser cell separation to reduce crack risks, high-density encapsulation, innovative connecting ribbons, and more, to increase the module efficiency while reducing total weight of the panel.

182 vs. 210

The major manufacturers have now formed into two groups when it comes to cell size – either 182 mm or 210 mm. Both camps are easy to identify, due to supply chain cooperation and partnerships. At SNEC it appeared as if the 210 mm may be gaining an advantage over 182 mm.

From pv magazine’s review of the cell and module producer booths in Shanghai, only Longi, Jinko and ZNshine were seen to stick to 182 mm solely, without any 210 mm products. On the other hand, Trina Solar, Risen, Tongwei, Chint, Maxeon, Eging, Suntech, Solargiga, GCL, and Jolywood were all offering 210 mm products only. Other major panel makers – including JA Solar, Canadian Solar, Seraphim and Haitai – have chosen to provide both options.

During the expo, Trina Solar released its new standard white paper for 210 mm wafer-based PV modules. The company intends to reduce supply chain costs by promoting the 210 mm type as the new standard.

BIPV development

More companies presented building-integrated photovoltaics (BIPV) products for what is described as a “blue sea” market segment. Jinko introduced BIPV color walls and BIPV roof products. Trina Solar released a systematic BIPV solution, the Trina Tile for rooftops. Yingli launched a new generation of BIPV products, including its “Glass-Overflow” series and external wall heat preservation + PV board. Chint presented its Telogy C&I rooftop BIPV solution. And Maxeon introduced the frameless Maxeon “Air” module, which can be easily attached onto roofs – doing away with the need for conventional mounting structures.

Bigger inverters

Along with the jump in module power ratings, inverter makers launched more high-power string inverters for 1500 V systems. The typical power level rose to 320 kW or more. MPPT currents rose to 45A or more to adopt the higher current from panels. GoodWe’s MPPT current rose further to 60A for its new inverter product, GW225KN-HT.

Meanwhile, to fulfill the requirement of incorporating storage in future PV plants, most inverter producers attached technologies to their inverter to ensure they will be compatible with the coming PV+storage integration. Even module makers like Trina Solar and Jinko released their own solar+storage inverters.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.