Allox Minerals, a Hyderabad-based natural resource company, has started producing electrode materials for Lithium-ion batteries under a government-owned company-operated model at International Advanced Research Centre for Powder Metallurgy & New Materials (ARCI) facility.

The company produces indigenous and economical lithium titanium oxide (LTO) anode and lithium ferrophosphate (LFP) cathode materials using a method developed by ARCI and is looking to scale up production according to the demand from the electric vehicle (EV) battery market.

“We have sufficient supply of Lithium to scale up the required production as and when the demand arises,” Anjani Sri Mourya S, director, told pv magazine.

“We aim to become a leading global producer of precursors for next-generation lithium-ion battery cells while creating the supply chain that enables the future energy requirements of the world, the global storage of renewable energy and electrification of transportation.”

Sources

Allox Minerals primarily deals in lithium and other rare earth minerals. The company, through a joint venture led by a corporation of the government of Telangana, is acquiring mining rights of lithium in Bolivia and Brazil, alongside mining of key battery related minerals in India to ensure an uninterrupted supply chain to the existing and upcoming industries. It has already tied up with two companies in Bolivia and Brazil for supply to India.

Mourya said, “Lithium is found in brine and rock form and needs to be processed into lithium carbonate and lithium hydroxide at the mining site as transportation of brines and spodumene is technically not possible to be processed at another location.”

“Allox has tied up with prominent technology providers for direct lithium extraction from brines and brine residual from the potential mines in South America that it aims to acquire along with the Government of Telangana.”

Forward integration

Currently, India has no known source of lithium and lacks the capability of the entire value chain from precursors of the raw materials to cell fabrication. As a result, the nation entirely depends on imported cells from China and uses them to manufacture battery packs.

Allox Minerals aims to become an anchor supplier to any cell fabrication companies and any other companies that want to produce anode and cathode materials. The company is also looking to forward integrate up to battery assembly.

“While we look at forward integration, we provide required opportunities for companies to backward integrate and create an entire ecosystem here in India,” Mourya told pv magazine.

The technology

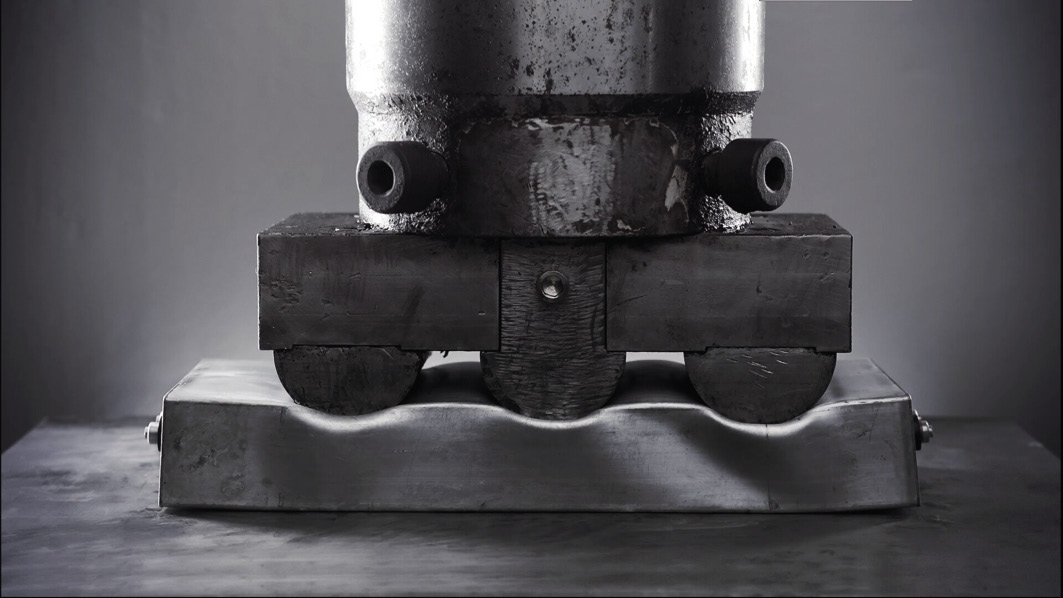

ARCI successfully synthesized carbon-coated LiFePO4 by a large-scale flame spray pyrolysis process followed by carbon coating and the electrochemical performance of the resulting material was found to be on par with commercial-scale carbon-coated LFP.

The method is economical and simple and has the potential to fine-tune the properties of the cathode produced.

Mourya said ARCI’s indigenous process is cheaper than with western counterparts’ technology and at par with Chinese companies. Besides, it produces a high-quality product, which is key for the long life and stability of the battery.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.