With approximately 44GW solar installed capacity and 40GW wind installed as of July 2021, and 450 GW RE target set for 2030, now is the time for India to create an ecosystem for recycling solar panels and other electric components, says Saloni Sachdeva Michael, energy finance consultant and author of a newly released report by the Institute for Energy Economics and Financial Analysis (IEEFA).

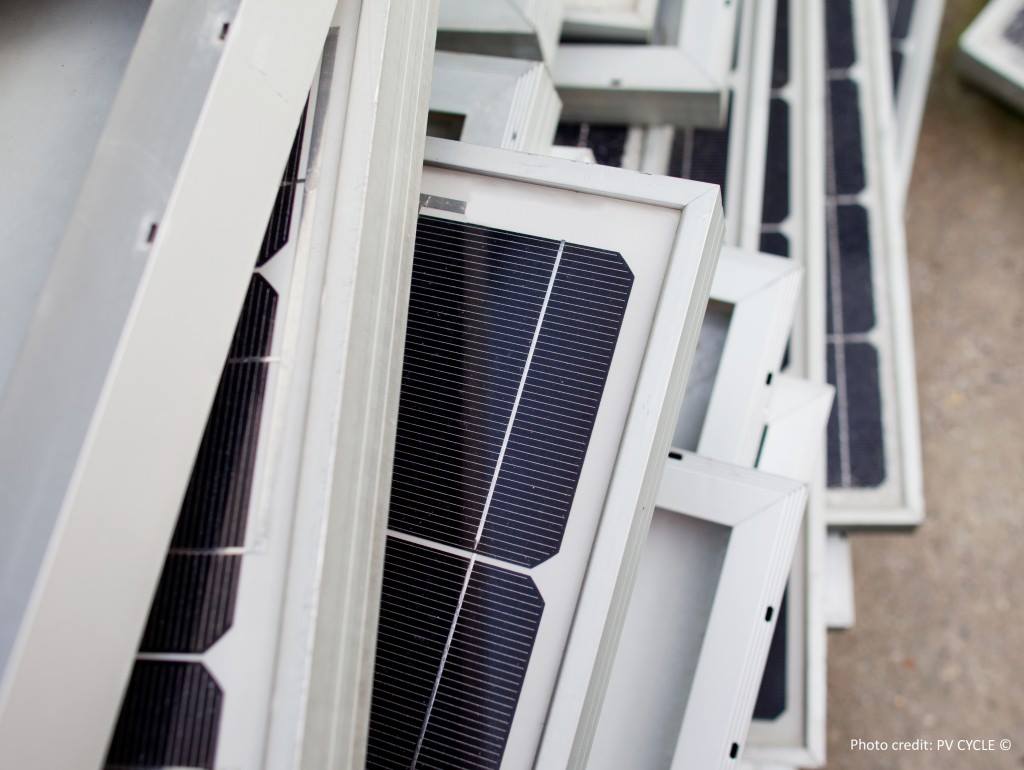

The adoption of a ‘circular’ approach to managing end-of-life solar photovoltaic (PV) modules, wind blades, and batteries would reduce future wastage of the high-value, critical raw materials needed for India’s massive clean energy transition, according to the IEEFA report.

The report notes India does not yet have dedicated renewable waste management and recycling policy and calls for a national framework to be developed for domestic recycling of solar PV in particular.

Moving from a linear, ‘make-use-dispose’ model towards one built on circular principles where resources are reused and recycled could accelerate decarbonization of the economy, cut waste, and reduce dependency on imports of raw materials for domestic solar module manufacturing, stated the report.

“Decarbonization based on circular principles is an opportunity to optimize usage of local resources, which would reduce dependency on imports. It would also reduce the amount of carbon emitted from raw materials used in the manufacture of wind, solar, and battery components and minimize waste.”

The potential value created by the recovery of raw materials from solar panels globally could reach US$450 million by 2030 and US$15 billion by 2050, according to International Renewable Energy Agency (IRENA) estimates cited in the report.

Barriers

To make recycling a reality, India will need to take steps to overcome challenges such as how to make solar panel recycling economical.

All stakeholders, including policymakers, regulators, manufacturers, assemblers, engineering, procurement and construction (EPC) players, financiers, and consumers, need to work together to reduce the costs of recycling, says Sachdeva Michael.

The growth of solar panel recycling can create new jobs, domestic supply chain stability, and ancillary markets that utilize the recycled materials in other products.

However, “The biggest barriers to implementation are lack of incentives for developers and consumers to give away used solar panels, absence of a structured policy or regulation that defines the ownership of the end-of-life panels and the cost of transporting the panels to the recycling plant.”

The report states that by learning from global initiatives, India can develop policies and regulations to define the recycling responsibilities and financial ownership of end-of-life solar panels by manufacturers, project developers, and consumers.

“Extended Producer Responsibility (EPR) schemes, for example, have become a powerful tool for promoting effective waste management solutions in a number of countries. The objective of EPR is to push producers (including thermal power generators, renewable energy developers and manufacturers) to factor in environmental costs as part of their project planning – both technical and financial.”

Recommendations

The report outlines recommendations in four key areas to encourage circular principles:

Policy and regulatory clarity. The Ministry of New and Renewable Energy (MNRE) and the Ministry of Environment, Forest, and Climate Change (MoEFCC) must work towards establishing standards for PV waste collection, treatment, and disposal. Developers and manufacturers must be encouraged to include the cost of decommissioning and recycling of PV panels in the bidding process, in power purchase agreements (PPAs), and in operation and maintenance negotiations. Further, the government tenders and contracts must include clear directions for the treatment and disposal of existing panels.

Producer Responsibility Organizations (PRO). A program to strengthen the capacity of the PROs to include RE waste collection, segregation, dismantling, and recycling needs to be developed and executed.

Circular supply chain and inventory. MNRE and MoEFCC need to track and monitor PV installation, performance, and life to quantify the number of panels reaching the end of life. One key solution is to create storage spaces for degraded panels instead of throwing them in landfills.

Innovative finance.There is a need to develop ancillary markets and pricing mechanisms for recycled products. Create a mechanism for adoption of environmental, social and governance (ESG) frameworks to enable domestic manufacturers to attract green finance to set up recycling plants alongside their manufacturing units.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.