From pv magazine 08/2022

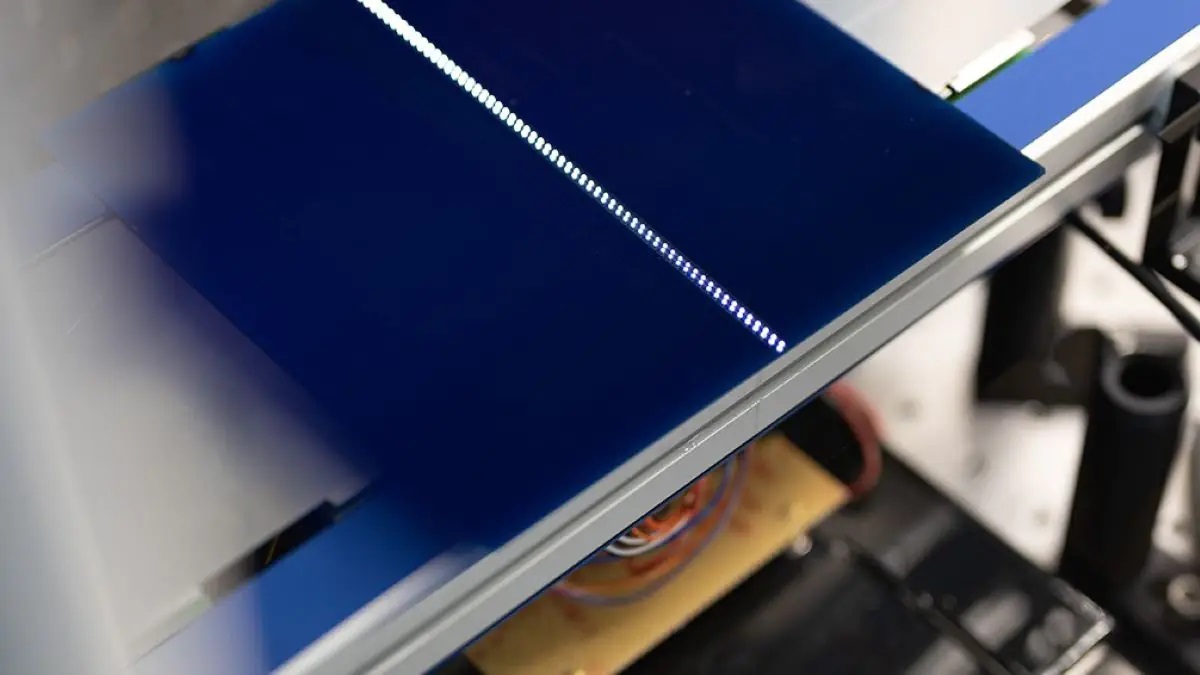

In PERC (passivated emitter rear cell) solar manufacturing, a passivation layer is applied to the rear side of the cell to improve stability. Then small “pockets” need to be opened up in this layer to allow more light to reach the active cell surface, and increase its conversion efficiency.

As PERC manufacturing grew, lasers fast became established as the quickest and most accurate way to complete this step. Processes have developed to keep up with rising throughput expectations and minimized handling, and more recently to adapt to larger cell formats. “Besides making sure that the machine itself is large enough to handle a 210 mm wafer, the major challenge is to retain or further improve the throughput,” says Thomas Kießling, senior product expert at laser processing specialist 3D-Micromac. “System suppliers have played their part in improving the speed of the scanner, and this is crucial in making sure that larger wafer sizes (M10, G12) can be processed with the same throughput as previously smaller wafers (M2-M6).”

Speeding up of the laser scanner has been coupled with on-the-fly processing innovations and other machine level improvements to keep throughput moving in the right direction in the last few years. State of the art throughput for LCO machines in the market today is up to 7,000 wph, with an available scanner speed of more than 60 m/s, more than double the speed of what was available just a few years ago.

Using an optical element to split a laser into multiple beams is one strategy to increase throughput further, and recent research from Germany’s Fraunhofer ISE demonstrated an approach that could push LCO throughput as high as 15,000 wph, keeping it well ahead of most other production stages.

Called polygon scan technology, the approach integrates a mirror wheel which can move the laser beam over the cells at a rate of 1,000 m/s, around 20 times faster than modern production tools. With the laser set to run at this speed, the challenge is to build a machine and a process that can maintain the precision to open up contacts in an exact pattern measuring just a few microns. “We had a prototype of the polygon scanner in our lab, and we saw that it was fast and had huge potential,” says Fabian Meyer, head of laser system development at Fraunhofer ISE. “The problem was when we put this into a machine, the overall processing didn’t become that much faster because there was still the handling.”

By working with an on-the-fly process, where cells move through the machine on a belt and are lasered without stopping, Meyer’s team was able to push the throughput much higher, with no loss in efficiency compared to cells processed on industry standard tools. “We are developing sensor technology designed specifically for the new system in order to achieve the required positioning accuracy despite the high speed,” says Meyer.

Nowhere fast

In 2022, however, the move away from PERC cell technology is gathering pace, and for now the cell designs they are turning to – primarily tunnel oxide passivated contact (TOPCon) and heterojunction (HJT) – don’t require an LCO step in their production. And while processes like Fraunhofer ISE’s might be able to demonstrate a cost advantage from increased throughput, or even better cell quality thanks to reduced handling, its unlikely that existing PERC manufacturers would be looking to upgrade.

3D-Micromac says it stopped the development of its LCO equipment in 2018, when competition from lower cost Asian equipment suppliers pushed it out of the market. So, for now it may be that there is limited market opportunity for any new LCO technology. On the research and development side, however, Meyer sees plenty of reason to continue investigating industrial laser processes for PV.

Reducing or eliminating silver from cell manufacturing is a key area of focus for scientists working in PV. This might entail new approaches to cell contacting and metallization, and many of the methods investigated here would again need an LCO step. “We see a huge part of the cell market that is trying to avoid silver,” says Meyer. “And there are two approaches gaining ground, both of which could make good use of a high speed LCO step.”

Meyer explains that replacing silver metallization with copper may also require LCO to open the passivation layer before plating contacts on top. And another approach where manufacturers are looking at creating aluminum pastes for both sides of a cell would likely need an LCO step. “There are also other laser processes which aren’t exactly contact opening but are aiming to improve the formation of contacts,” Meyer says. “It’s definitely an important research topic.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.