From pv magazine Global

Researchers from the University of Melbourne and the University of Manchester have designed a direct air electrolysis (DAE) module to produce hydrogen for applications in remote areas.

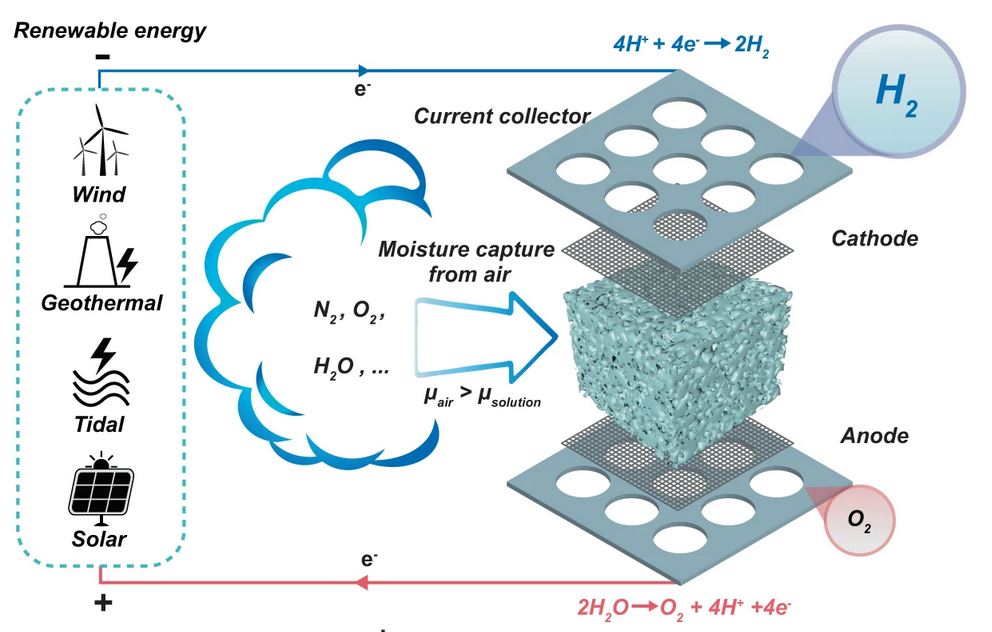

The device uses moisture in the air to directly generate hydrogen via electrolysis, without any input of liquid water. The module consists of a water harvesting unit in the middle and electrodes on both sides paired with gas collectors. It can be paired with both photovoltaic and wind power generators, as well as with any generator relying on renewable energy sources.

The water harvesting unit also works as the reservoir to hold the electrolyte.

“Porous medium such as melamine sponge, sintered glass foam is soaked with deliquescent ionic substance to absorb moisture from the air via the exposed surfaces,” the scientists said. “The captured water in the liquid phase is transferred to the surfaces of the electrodes via diffusion and subsequently split into hydrogen and oxygen in situ which are collected separately as a pure gas, since both electrodes are isolated from air.”

They said the reservoir between the endplate and the porous foam acts as an air barrier and a buffer for the ionic solution at the excessive fluctuation of the air humidity. They noted that it avoids the overflow of the electrolyte from the DAE module or the dry-up of the wetted foam.

“The foam filled with ionic solutions forms a physical barrier that effectively isolates hydrogen, oxygen, and air from any mixing,” they said.

The group built two prototypes relying on solar and wind power. They constructed the solar-driven free-standing hydrogen tower with a solar panel and five DAE modules stacked in parallel.

“The footprint of the tower is no more than the solar panel, meaning our DAE will not occupy extra land, which can be costly in some areas,” they said.

The proposed system configuration was tested for twelve days with an outdoor temperature varying from 20 C to 40 C and the relative humidity ranged from 20% to 40%. The device was able to produce around 1500 ml of hydrogen in a day and showed a Faradaic efficiency of around 95%. The Faradic efficiency is the measure of the efficiency with which the electrons participate in a given electrochemical transformation.

“After keeping the above DAE module unattended in air for eight months, the Faradaic efficiency of hydrogen remains around 90%, without any maintenance,” the academics said. “The prototype achieved automated steady hydrogen production depending on the solar intensity under varying weather conditions.”

The scientists presented the novel tech in “Hydrogen production from the air,” which was recently published in Nature Communications.

“Further improvement of the surface-to-volume ratio by engineering channels or increasing the aspect ratios of the sponge material will guarantee the rate of water uptake which is essential to the upscaling of the DAE units,” they concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.