From pv magazine Global

A group of plant manufacturers, metrology companies, and research institutions led by Germany’s Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) has optimized several steps of the production process for silicon solar cells, resulting in a throughput of 15,000 to 20,000 wafers per hour – approximately double the usual amount.

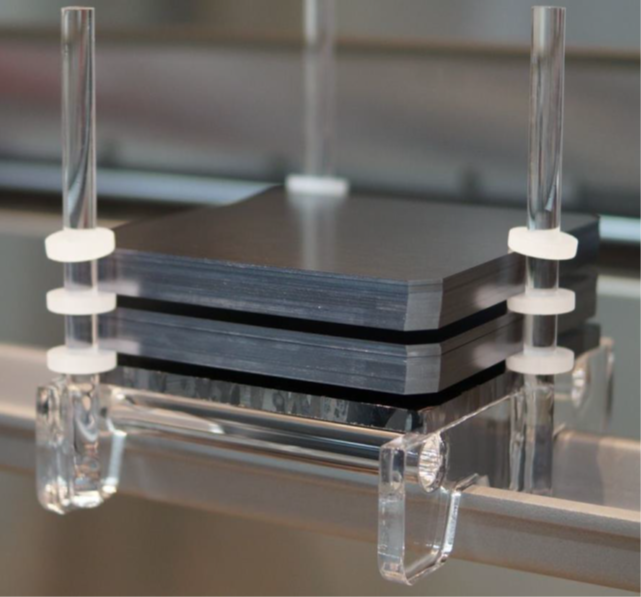

One of the innovations involves the integration of the diffusion process, combining the doping of solar and the thermal oxidization of the wafers in a single step. Thermal oxidization of wafers is usually performed in furnaces, with wafers transported through the furnace in so-called quartz rack boats. Wafers are usually placed in these boats individually, but the researchers optimized the process by stacking the wafers on top of each other in special quartz boats. The resultant oxidization process creates the final doping profile and achieves surface passivation at the same time, increasing the throughput of the process by a factor of 2.4.

In the next step of the process, contact with the imprinted electrodes on both sides of the silicon solar cells is formed in inline furnaces. To increase throughput at this stage, the researchers installed a considerably faster belt speed in the furnace, bypassing the standard need for a significantly larger heating chamber. The group compared the quality of the sintered solar cells with today’s standard, and found that throughput increases significantly without compromising the efficiency of the solar cells.

Whereas processes like these were accelerated, others “needed to be reinvented from scratch,” said Florian Clement, project manager at Fraunhofer ISE. In one of the new developments, the researchers implemented a new on-the-fly laser equipment that continually processes the wafers as they move at high speed under the laser scanner. For the metallization of solar cells, the consortium introduced rotary screen printing instead of flatbed screen printing, the current standard process. This technique could considerably reduce the amount of silver needed for the production of solar cells, while maintaining high levels of power conversion efficiency.

Finally, the researchers devised two new concepts to speed up the testing of cells by future production lines: a contactless method and a method using sliding contacts. Cells can be accurately measured at a continuous speed of 1.9 meters per second with the new methods. The team has filed for a patent for the contactless method.

The consortium is presenting detailed results from the research project this week at the World Conference on Photovoltaic Energy Conversion in Milan, Italy. China still produces most of the world’s silicon solar cells – as high as 78% in 2021 – so the group sees the results of the project as a way to make European factories more competitive.

“In order to deploy more solar installations as quickly as possible and to make our supply chains more robust, Europe should re-establish its own production centers for high-efficiency solar cells,” said Ralf Preu, division director of PV production technology at Fraunhofer ISE. “By boosting throughput and making production technology more resource-efficient, we can cut costs considerably and unlock sustainability potential that we will be able to leverage thanks to process knowledge and engineering excellence.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.