From pv magazine Global

Redox flow batteries are one of the most attractive technologies for large-scale stationary storage applications due to their low capital cost, excellent safety, and environmental credentials. Their most unique feature is the independent scalability of energy and power. However, the latter is normally not possible in hybrid flow battery systems.

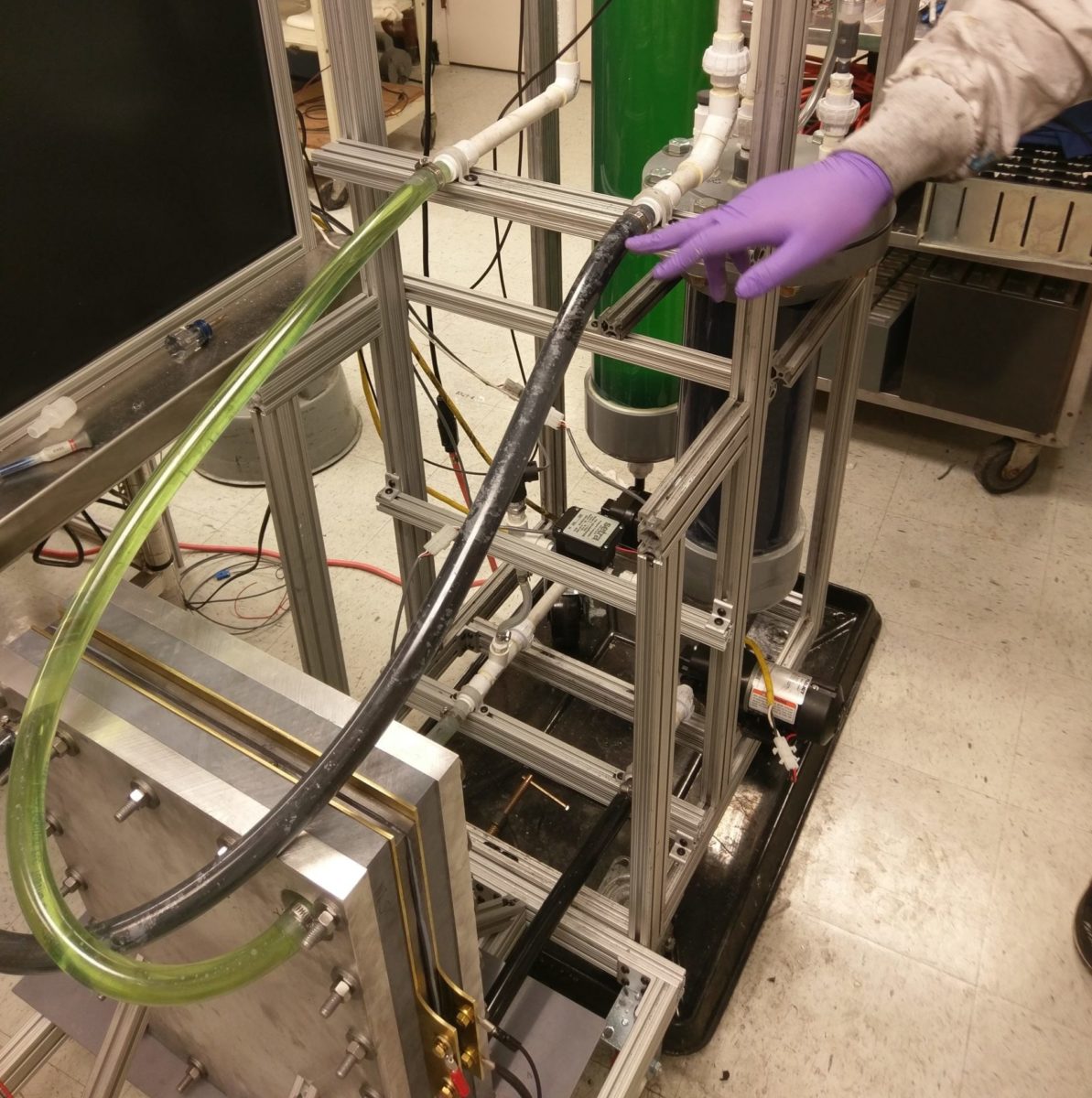

Now, researchers at Case Western Reserve University (CWRU) in Cleveland, Ohio, have come up with a concept for a slurry iron redox flow battery. It offers the potential for very low-cost, large-scale energy storage with safe and sustainable materials. By incorporating a conducting carbon slurry into the negative electrolyte of an all-iron flow battery, the researchers have ensured that the iron plating reaction occurs in such a way that makes the decoupling of power from energy possible for their hybrid flow battery system.

“Our iron slurry battery has advantages over the hybrid iron flow battery, where metal is plated into the electrochemical cell,” Nicholas Sinclair, research engineer at the CWRU Department of Chemical and Biomolecular Engineering, told pv magazine.

The slurry electrode allows for the plated metal to be directed into tanks for long-duration energy storage, Sinclair said. The hybrid system is limited in how much energy they can store by how much metal fits into the cell.

“In the slurry system, you can simply add more electrolyte and make the tanks bigger without changing the size of the electrochemical cell, which determines the power output,” Sinclair said.

The researchers described the scalability of the novel redox flow battery in “A perspective on the design and scale up of a novel redox flow battery” which was recently published in MRS Energy and Sustainability. They said that while the scaling of flow batteries is simple due to their modular nature, it becomes complicated when making large-scale increases in a single step. Nonetheless, their proposed battery technology is now edging toward commercialization.

“The battery technology was developed under an ARPA-E program for several years. During that project the technology matured to a point where commercial scale units are now being designed and tested by a company who licensed the technology from us,” said Sinclair. “We have follow-on funding for developing the technology further and expanding it to other battery chemistries as well.”

While the final price tag of the novel battery could change when it is commercialized, cost estimates calculated under the ARPA-E project stand at around $50/kWh.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.