New 400 W-plus shingled solar modules are on the market, serving demand for high-powered, more durable, sleek all-black products. Chinese cell giant Tongwei is responsible for the new modules – its Terra series released in 2022. The Terra series comes in power classes of 400 W to 430 W, with efficiencies ranging from 20.1% to 21.7%.

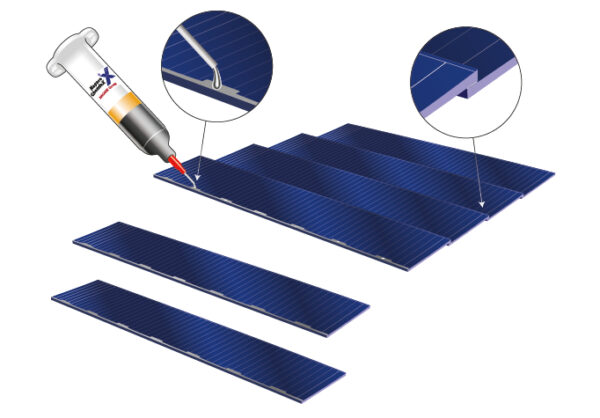

Tongwei is notable as a major Chinese supplier embracing shingling, which involves cutting solar cells into strips which are then interconnected through electrically conductive adhesive (ECA), slightly overlapping along the long cell edge.

The head of Tongwei’s shingled module department, Yan Li, says shingled products offer “advantages in power, efficiency, and reliability” and technical advantages because of “high-density packaging and flexible interconnection.”

“However, we believe that the differentiated Terra high-efficiency shingled modules with aesthetic appearance will target some markets, and increase our share and brand influence in the residential segment,” says Li. Alongside sleek aesthetics and power, shingling also delivers durability, Li claims, due to its “low hot-spot risk, resistance to micro-cracks and exceptional mechanical load performance.”

Tongwei, which has 70 GW of annual cell capacity – and plans to hit 130 GW to 150 GW by 2026 – reports having 6 GW of Terra lines, while module capacity has reached 14 GW, including half-cut series’.

IP claims

While Tongwei’s adoption of shingling represents a major development of the technology at scale, the commercialization of shingling has been years in the making. Silicon Valley-based Solaria Corporation, founded in 2000, began selling shingled PowerXT modules in 2016. Solaria claims to hold “over 250 issued and pending patents in the field,” many of which, presumably, relate to shingling.

The Californian company has robustly defended what it considers its intellectual property (IP). In June 2022, it settled a patent infringement lawsuit filed in 2020 against Sino-Canadian manufacturer Canadian Solar for allegedly infringing its shingling technology.

Solaria wants to merge with installer Complete Solar and float the resulting Complete Solaria business as a vertically-integrated company similar to SunPower. Complete Solaria would make shingled PowerXT modules with an output of around 400 W under a “low capex [capital expenditure] model,” with production “by manufacturers in Thailand, Cambodia, Vietnam, and India.”

Robust IP

Tongwei says it began module R&D in 2016 and attached importance to the establishment of an intellectual property system. “From the beginning of the shingled product project, Tongwei has already started the layout in the patent end,” says Li. “After seven years, Tongwei has formed an independent shingled technology roadmap.”

George Touloupas, senior director of technology and quality at quality assurance provider Clean Energy Associates (CEA), points to Tongwei’s statements the company has its “own way of interconnecting,” free of IP concerns. Touloupas adds, “The shingled module chief technology officer is formerly from SunEdison and he is bringing his shingling experience from that company to Tongwei.”

Peering under the hood, Touloupas observes that the interconnection approach used by Tongwei appears to have additional benefits. “Tongwei is also exploring a different interconnection technology where shingled cells follow a jagged pattern, which is even more resilient to hot-spots and has lower loss due to shading.”

Matrix layout

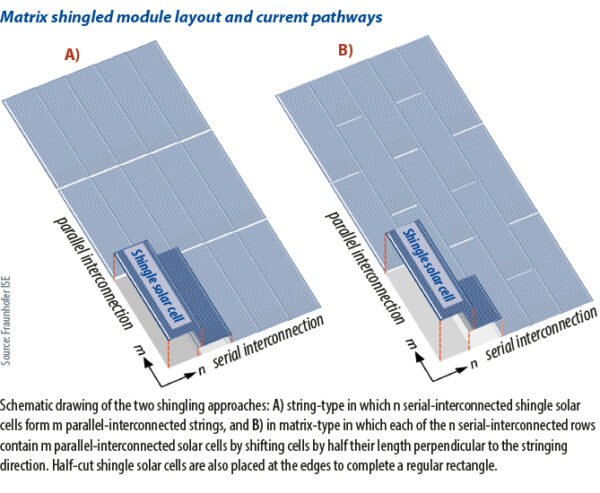

Researchers at Germany’s Fraunhofer ISE published test results from such a shingled-module cell layout in the journal Progress in Photovoltaics in 2021. In the paper, the researchers term the technique a “matrix layout” whereby the cut cell pieces are placed in an offset pattern, “by half a cell length” – with half-cut shingle cells placed at the edges to result in a standard rectangular module format.

“By shifting the solar cells from row to row by half a cell length, an additional parallel interconnection of all solar cells within each row is achieved,” the researchers wrote.

The Fraunhofer ISE team tested matrix shingled modules in various shading scenarios, including with shading diagonally across the module, and found that the matrix design resulted in significantly increased energy yield. Electric current could bypass shaded areas more effectively due to the offset cell layout. The layout also reduced the risk that mechanisms causing hotspots – a result of partial shading – would occur.

As ideal, unshaded locations for solar become increasingly scarce, the Fraunhofer researchers concluded that the matrix layout would become increasingly valuable. “Huge potential for solar power generation meets a huge variety of irregular shading conditions, making shading tolerance a very important aspect,” wrote the academics.

Challenges remain

Advances in shingling technology, and its adoption in manufacturing at a larger scale, point to the technology potentially moving into a new era of development. Competition from other technologies will remain fierce, however.

“Four or five years ago, shingled modules had about [a] 10% efficiency advantage compared to ordinary – at the time – full-cell, four-busbar modules; that’s not the case any more,” says CEA’s Touloupas. “With the introduction of half-cut cells, multi-busbar, paving, or tiling; this 10% module area efficiency advantage has evaporated.”

As Tongwei and other shingling proponents argue, there are a host of advantages beyond efficiency. The use of ECA rather than busbars, which contain lead, is one such advantage – adding environmental credentials to the shingled approach, alongside durability, shading tolerance, and aesthetics. As with some other high efficiency technologies, the silver content in ECA will have to continue to come down for its use to be sustainable in larger volumes (see box).

Low-silver ECA

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.