From pv magazine Global

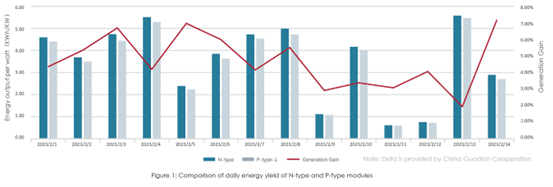

A case study conducted at a 30 MW PV project developed by China Guodian Corporation (CGC) compared the performance of p-type PERC and n-type TOPCon modules under the same installation conditions. The study demonstrated an increased energy yield of just 5% for the n-type modules, over a two-week period in February 2023.

The 30 MW project studied was developed by CGC in Jixian, Tianjin Province. The project features 20 MW made up of two different 545 W, p-type PERC modules from unnamed manufacturers, with the remaining capacity made up of 555 W n-type TOPCon modules supplied by JinkoSolar. All of the modules are installed on fixed tilt racking at a 30 degree angle, and connected in strings of 26 modules with one 225 kW string inverter for every 17 strings.

The performance of the two module types was analyzed during the first two weeks of February 2023. During this period, the n-type modules were shown to have generated an average of 169.53 kWh per kW installed, a 5.02% increase on the 161.43 kWh/kW achieved by the best-performing p-type module at the site.

Module manufacturer JinkoSolar, which supplied the n-type modules to this project, says this data illustrates the reported advantages of TOPCon over PERC in action. The manufacturer cites the n-type modules’ higher efficiency and better bifaciality as key reasons for the increased performance. Better bifaciality (around 70% for PERC and 80% for TOPCon) could account for a yield increase of 1- 1.5%.

With only two weeks of data, collected during the coldest part of the year in Tianjin Province, other advantages are more difficult to take directly from this case study. However, JinkoSolar also cited its n-type modules’ lower degradation rate – 1% in the first year followed by 0.4% per year as likely to bring a yield increase of around 1.8% over PERC’s typical degradation of 2% in year one followed by 0.45% per year.

Finally, it cited the lower temperature coefficient of n-type modules – 0.29% performance loss per C of temperature increase, versus 0.35% for PERC modules – as responsible for a further 2% yield boost, noting that this advantage would be more visible at the project studied in the summer months when temperatures can reach 30 C and higher.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.