From pv magazine Global

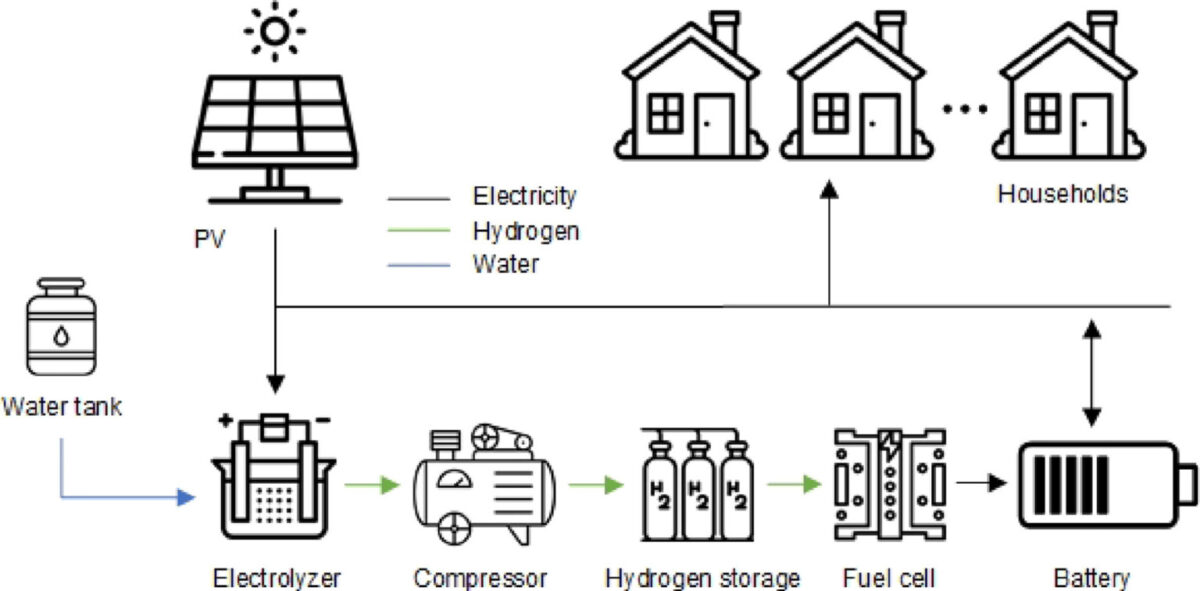

Scientists at the Delft University of Technology in the Netherlands have developed a new methodology for the design and component sizing of off-grid, residential PV–battery–electrolyzer–fuel cell systems that use the generated hydrogen for long-term energy storage and the battery for short-term storage.

They claim the system may be a suitable solution in rural areas where transmission and distribution networks are difficult to access.

“The proposed approach adopts a load sizing factor as the key input parameter, it determines the extent to which the load demand in winter times is supplied by hydrogen to meet the seasonal imbalance,” the researchers stated, noting that the energy system is intended at serving an energy community consisting of several buildings. “In addition, a rule for selecting a proper load sizing factor to achieve the defined objectives, such as self-sufficiency.”

In the proposed system configuration, the electrolyzer is mostly utilized through surplus PV power in summer times to produce hydrogen, which is then delivered to a compressor, stored in tanks, and used for electricity production via the fuel cells in winter. Not all the surplus solar power, however, should be used to produce hydrogen, as this would increase the project’s Capex.

The innovative part of the system, the research group explained, consists of the fact that it divides load demand in winter times into two parts, of which one is met by PV and battery storage, while the other one is met by hydrogen when PV generation is not available and the state of charge of the battery is below 40%.

“The PV sizing follows the approach in that annual PV generation equals annual load demand,” the academics emphasized, adding that the battery size will be strictly dependent on the days of autonomy of the energy system and the project location. “The required PV generation for producing hydrogen is determined by both the efficiency of the electrolyzer and the fuel cell.”

The Dutch group said the system should be sized in a way that loss of load probability (LLP), which it defined as the ratio between the load demand that cannot be met by the energy system in a year divided by the total annual load demand, is always equal to zero. “The lower the LLP is, the more stable and reliable the energy system is,” it further explained.

The academics conducted a series of simulations and found the system can achieve a levelized cost of energy that is still higher than the energy price in the Netherlands, although it also found that the integration of the electrolyzer and the fuel cells with the solar-plus-storage installation is able to increase the reliability and security of the energy supply.

“However, as technology advances, the costs associated with hydrogen storage tanks and electrolyzers are expected to decrease, thereby increasing the affordability of this type of energy system,” they stressed. “In addition, the efficiencies of electrolyzers and fuel cells will also improve at the same time, which will also increase the system’s overall efficiency.”

Looking forward, the scientists said they want to investigate other cheaper options than the tank for hydrogen storage and reduce the system costs. “In future work, it is worth investigating the use of heat to meet the heat demand of the end-users to help them save heat costs as well,” they concluded.

They introduced the new methodology in “An approach for sizing a PV–battery–electrolyzer–fuel cell energy system: A case study at a field lab,” which was recently published in Renewable and Sustainable Energy Reviews.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.