From pv magazine 05/23

In mid-April, R&D staff at Tandem PV, a solar manufacturer in San Jose, California, carefully packed a batch of modules to ship to the DoE’s PV Accelerator for Commercializing Technologies (PACT) in New Mexico for a series of perovskite-specific reliability tests.

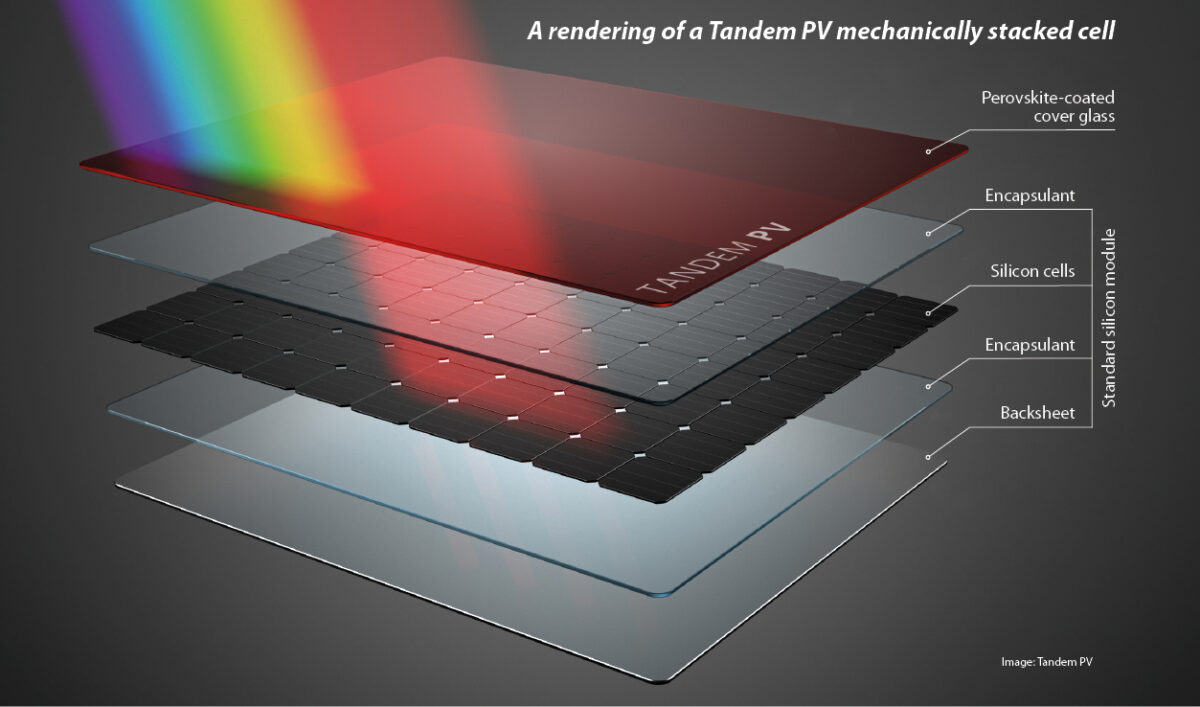

The performance tests are the latest step that seven-year-old Tandem PV is taking toward commercializing its mechanically stacked perovskite-silicon tandem (four-terminal) PV technology.

Tandem PV is collaborating with potential customers and production partners. It has fabricated 100 cm2 panels which have passed IEC 61215 accelerated tests with academic partners, and has received initial data on passing triple-length duration IEC 61215 tests, according to CEO Colin Bailie.

The initial application Tandem PV will target is rooftop solar. “Financially, rooftop makes sense for us and for our customers,” says Bailie, an alumnus of the McGehee group at Stanford University. “Residential module manufacturers are keen to boost power output and installers want solutions that bring down installation costs.”

Tandem PV last year raised $13 million in series A and non-dilutive funds and is looking at breaking ground on a manufacturing facility and exploring finance options. “We have to be patient,” adds Bailie. “The PACT tests run six to 18 weeks; that timing cannot be accelerated.”

PACT testing

Tandem PV is one of multiple teams using PACT’s independent performance and reliability testing for all varieties of perovskite PV modules and mini modules, including field testing.

“Any companies or researchers serious about commercializing can bring their modules to us, it is similar to ViperLab in Europe,” says Joshua S. Stein, PACT director and senior scientist at Sandia National Laboratories.

PACT has worked since 2021 on a common set of perovskite testing protocols to enable comparable results. Its services are provided by DoE entities such as Sandia; the National Renewable Energy Laboratory (NREL); and the Los Alamos National Laboratory; as well as Black & Veatch, an engineer; CFV Labs, which is privately owned; and the Electric Power Research Institute, a nonprofit.

In addition to testing, PACT grants bankability aid to companies with qualified modules and is funded with part of the $25 million annual budget the DoE’s Solar Energy Technologies Office (SETO) has to support perovskite solar commercialization. SETO has published minimum targets based on perovskite industry input, as well as the “The Path to Perovskite Commercialization: A Perspective from the United States Solar Energy Technologies Office,” a paper that appeared in ACS Energy Letters in April 2022.

“One strength is the large community on the R&D side,” says SETO Manufacturing and Competitiveness Program Manager, Markus Beck. “And there are several early-stage and new startups emerging.”

North American activity

A separate initiative is the US Manufacturing of Advanced Perovskites (US-MAP) group, a consortium of industry and research groups which was formed in 2020 to move members toward larger-area devices and initial production with high-yield and high reliability processes. There are now 11 industrial members – up from six at launch – plus four research groups.

“US-MAP supports cross-cutting capabilities to reduce its members’ R&D costs and lower technology risks for potential investors,” says Joseph Berry, director of the US-MAP consortium and a senior scientist at NREL.

Members work with NREL, the University of Washington’s Washington Clean Energy Testbeds, the University of North Carolina at Chapel Hill, and the University of Toledo.

The six original PV developers in the group are BlueDot Photonics, CubicPV (a merger of 1366 Technologies and Hunt Perovskite Technologies in 2021), Energy Materials Corp., First Solar, Swift Solar, and Tandem PV.

Newer members include four process and materials companies (Dow, FOM Technologies, Ntact, and Tau Science) and PV developer Caelux.

North of the border, six-year-old Rayleigh Solar Tech – based in Halifax, Nova Scotia – recently commissioned a pilot line for its flexible and lightweight perovskite solar PV technology. The Canadian company also verified 14.8% outdoor efficiency on an 85 cm2 encapsulated thin film module with the Austrian Institute of Technology. It targets indoor and outdoor PV applications where its flexible and lightweight format is an advantage.

Rayleigh’s core PV platform uses widely available, non-noble materials with a cell-stack that can be produced using a scalable roll-to-roll manufacturing process, according to co-founder and chief technology officer Sam March. The company is collaborating with Magna International, a tier-1 automotive supplier, on an injection-molded auto body panel application, and is seeking more partners for product development.

Rayleigh Solar Tech has raised a total CAD 10 million ($7.4 million), including non-dilutive funds from Sustainable Development Technology Canada (SDTC), a government body. At least three other Canadian companies in the perovskite PV ecosystem have received SDTC support: British Columbia-based Solaires Enterprises; Ontario-based QD Solar; and G2V Optics, in Alberta.

Activity is clearly increasing. “I see more startups emerging in North America, such as spinouts from R&D labs, possibly more than in Europe,” says Daniele Braga, head of sales at Fluxim, a Swiss vendor of characterization and modeling tools for emerging PV devices.

Braga says that Fluxim’s sales into academia and industry have increased markedly in the past year or two. “The Inflation Reduction Act has had a huge effect on solar PV investment and R&D in the US, including perovskite solar and tandem technologies,” says Braga.

Pushing the limits

North American universities and research labs are making strides to improve perovskite solar cell performance and make it more competitive.

Jinsong Huang’s group at the University of North Carolina is researching perovskite solar cell and module approaches and has demonstrated, since 2014, an open-air blade-coating method and slot-die coating as low cost, high yield processes. The group has demonstrated modules for perovskite cells including single-junction, tandem, and bifacial devices, that minimize cell-to-module efficiency losses.

Nature Energy recently accepted “Design optimization of bifacial perovskite minimodules for improved efficiency and stability,” a paper describing how the North Carolina group achieved low degradation in single-junction perovskite mini modules, even after 6,000 hours at 60C, plus or minus 5C, according to Huang. The Huang group has also validated a model to identify pathways to increase module efficiency. Perotech, a University of North Carolina spinout, will be developing flexible perovskite modules.

In March, researchers from the Yang Yang group at the University of California, Los Angeles (UCLA) made the news when Midsummer, a Swedish copper indium gallium selenide (CIGS) PV manufacturer – along with Pioneer Materials, a thin-film deposition company – announced a four-terminal perovskite-CIGS tandem solar cell with 24.9% efficiency. The UCLA researchers said a two-terminal perovskite-CIGS tandem cell suitable for mass production is the goal.

Yanfa Yan, a researcher for the Wright Center for Photovoltaics Innovation and Commercialization at the University of Toledo, has supervised research alongside the University of Toronto, the University of Washington, and Northwestern University, as well as the Swiss Federal Laboratories for Materials Science and Technology (the Eidgenössische Materialprüfungs- und Forschungsanstalt, or EMPA). In February, Yan also published “Rational design of Lewis base molecules for stable and efficient inverted perovskite solar cells” in Science. The researchers noted modified 1.05 cm2 cells achieved an improvement on fill factor and open-circuit voltage and a power conversion efficiency greater than an undoped cell – 23.9% versus 22.6%. There was reportedly no degradation after 1,500 hours (under 1 sun at 85C). “Our next goal is to realize such long-term stability in perovskite modules,” says Yan.

In December, NREL staff and scientists from the University of Toledo and the University of Colorado published all-perovskite tandem cell results in Science. The cells achieved a high open-circuit voltage of 2.2 V and 27.1% efficiency using a method which manipulated the constituent layers of the wide-bandgap layer to reduce defect density. It resulted in 20% layer efficiency and less than 5% degradation over 1,100 hours of operation under 1.2 suns at 65C. NREL researchers are also advancing low-cost approaches on silicon tandem, single junction perovskite, bifacial single junction, and all-perovskite tandem devices.

In November, a team featuring Northwestern University’s Ted H. Sargent as corresponding author, announced an all-perovskite tandem cell advance in Nature. Researchers regulated the wide bandgap layer perovskite surface with a positively charged ultra-thin chemical coating to maximize voltage. The resulting device had an open-circuit voltage of 2.19 electron volts and NREL-certified 26.3% efficiency. The 0.049 cm2 prototype maintained 86% of initial efficiency after 500 hours.

“The next research areas are to increase efficiency and stability with what we’ve learned, also scaling the small-area device size, from cell to module,” says the University of Toronto’s Hao Chen, the co-lead author of the paper.

Sargent says that the group at Northwestern will continue to research perovskite technologies along these lines – both basic and engineering research. He adds that the size of his group will double.

In July, Princeton researchers led by Yueh-Lin Loo published a paper in Science about interface-stabilized, all-inorganic perovskite solar cells. The work involved innovations including among the stack materials and the crystalline domain size of the perovskite absorber, which improved stability. The cell, with a champion efficiency of 17.4%, did not degrade after more than 3,500 hours at 35C while continuously illuminated. The team also reported a method to accelerate the aging of perovskite cells by heating them under illumination.

There is much tandem and single junction research under way and academics will aim to demonstrate larger, more stable devices, modules, and processes.

“While perovskite-silicon tandems are drawing attention, there will be room for different approaches based on thin films, such as perovskite-CIGS and all-perovskite tandems, including bifacial designs,” says Ayodhya N. Tiwari, head of the thin-film PV lab at Switzerland’s EMPA. “Even with silicon dominating, I believe all-thin-film-tandem PV will be a substantially large segment of the PV market in future.”

By Valerie Thompson

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.