From pv magazine USA

What sets Sunfolding’s terrain-following tracker apart from other designs is pneumatics, a 360-year old technology that converts power into movement.

Traditional trackers are mechanically more complex, which can make installation and maintenance costly. Sunfolding developers discovered that pneumatics offered a simpler approach with advantages in certain solar designs. Some of those advantages include a reservoir (or bladder) for air storage so they can continue operating through loss of power.

They can also operate through loss of air and can run continuously without the threat of overheating. Read more about solar and pneumatics in Sunfolding’s white paper. Without batteries or metal drive components, the pneumatic technology is also able to withstand extremely low temperatures where traditional trackers have had issues.

As noted by Chip McDaniel in Industrial Equipment News, pneumatics offer the advantage of simplicity, low cost and reliability, providing “a quick path to motion,” providing significant force in a small space.

The patented AirDrive technology used by Sunfolding was invented by Leila Madrone, company founder and chief technology officer. Madrone is a roboticist, having received both her bachelors and masters in electrical engineering and computer science from MIT, with a focus on robotics and mechatronics. Early in her career she worked on automation for the genomics industry and the commercialization of NASA robotics hardware. Founded in 2012, Sunfolding was spun out of MIT’s Otherlab. In 2016, the company won a $4.2 million ARPA award for its “pneumatically-actuated PV tracking system.”

The AirDrive system

At the heart of its tracking system is the AirDrive. Based on Madrone’s invention, it consists of flexible bladders (shown above) enclosed in a metal housing with a bladder to the east and one to the west. When the bladders are pressurized to different levels, one side expands and tilts the solar structure in the opposite direction. AirDrive X actuators in the Sunfolding system reportedly weigh less than 50 pounds. Wes Fuller, vice president of sales and strategic partnerships, told pv magazine USA that two people can lift them and attach them to posts anchored in the ground. The automotive-grade pneumatic harnesses connect with the supply air system—one for each 5 MW. These systems come pre-assembled and can be dropped into place on site.

The pneumatic system has fewer critical points of failure than traditional mechanical systems, dramatically reducing maintenance costs, according to Sunfolding. The AirDrive X actuator uses advanced polymers supplied by DuPont, helping them weather exposure to wind, heat, rain and snow.

Sunfolding’s first product was the T29 tracker, which reportedly changed the tracker landscape with its use of pneumatics, is installed in 39 projects in 12 states including sites in California, Colorado, Georgia, Pennsylvania and Texas.

The TopoTrack, introduced in September 2022, is designed for varied terrain. Like the T29, it uses the AirDrive technology, but has mechanically independent, scaled down tracker rows.

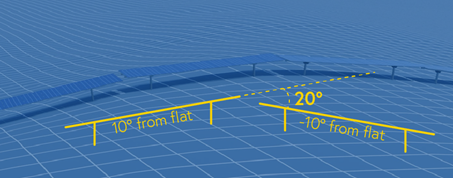

The company reports that TopoTrack’s rows are 10 times shorter than traditional trackers, and that they can provide 20 degrees of variation between trackers, thus improving slope tolerance between the rows and allowing for articulation in terrain, including complete directional change in terrain if needed.

The design uses two posts, two actuators and two purlins. As a result of the tracker’s flexibility and simplicity, Sunfolding says that the tracker’s footprint across a project site can be increased when tracker-to-tracker spacing is reduced. Fuller noted that TopoTrack can reduce the need for grading by an estimated 97%, thus resulting in further cost savings.

Headquartered in Alameda, Calif., Sunfolding’s posts, actuators and purlins are made in the U.S. The company partners with auto industry component suppliers to manufacture the AirDrive, and reports that 90% of its bill of materials are sourced from a 250-mile radius of its manufacturing facility in the Midwest, enabling short lead times and reducing procurement risks.

TopoTrack was recently deployed on a site with strict environmental protections in place. This site featured complex terrain in a high snow load location. TopoTrack technology reportedly enabled the customer to perform zero grading on this site, greatly minimizing the cost of handling complex terrain and permitting risk.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.