Researchers from the City University of Hong Kong have proposed a blockchain-based solar passports framework as an effective solution to monetize solar PV plant assets in India. It states such material passports will fill in the data gap during the entire life-cycle of PV modules—from raw material sourcing to manufacturing to dispose of—and aid in the reuse of raw materials and products in line with circular economy principles.

The framework would allow verification of the origin, quality, and quantity of materials used in PV panels, thereby boosting recycling investors’ confidence and facilitating the secondary market for PV assets.

The researchers, Nallapaneni Manoj Kumar and Shauhrat S. Chopra, highlight the urgent need for integration of the proposed framework into existing or new policies and regulations in India.

Key findings

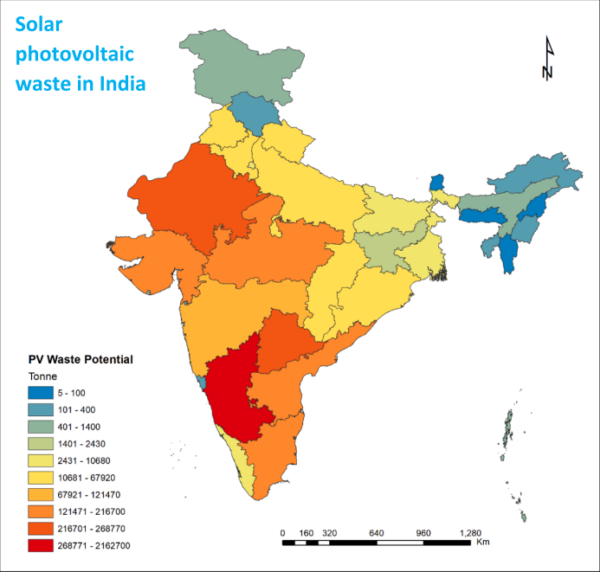

The researchers project India’s PV waste potential at 1.95 megatons resulting from the grid-connected solar PV facilities installed in the nation before January 31, 2019.

The researchers modeled material recovery under three recycling techniques, namely, the standard industrial procedure as the baseline scenario, the thermochemical demanufacturing procedure, and the delamination procedure.

In the baseline scenario, the PV waste is directly subjected to shredding without removing a PV panel’s rear-side junction box. The shredded PV panels are then processed using metallurgical and induction sorting methods to recover materials.

In contrast, in the thermal and chemical scenario, the end-of-life (EoL) PV panels are treated differently, where the junction boxes at the rear side of the PV module and cables are separated first. Thereafter, the remaining PV waste is subjected to thermal treatment followed by chemical treatment to recover materials.

Similarly, in the delamination scenario, the junction boxes and cables are manually removed from EoL PV panels. The glass component is then isolated from solar cells during the cutting step of the recycling process, and thermal approaches are applied to recover useful materials from the residual waste.

The analysis indicates that the front glass of the PV module, which constitutes approximately 59.51% of its weight, is the most prevalent component for material recovery. Specifically, for every 1 tonne of PV waste, 595 kg of glass can be recovered, with the potential to recover around 89.6 to 98% of the glass under different recycling scenarios.

[The recycling processes utilizing thermal and chemical treatments and the delamination exhibited similar yields of 583.23 kg per tonne, compared to 532.98 kg per tonne recovered under the baseline scenario.]

After glass, aluminum constitutes the second most proportion of a PV module’s weight, accounting for approximately 16.71% (with about 14.7% in the frame and nearly 2.01% in the solar cell). Considering the total estimated PV waste of 1.95 megaton, 286,937 tons and 3,904 tons are attributed to the aluminum in the frames and solar cells of the modules, respectively.

Steel, another material commonly used in PV panel frames, comprises around 8.65% of the module’s overall weight. The weight of EoL PV modules is 1.95 megatons with 168.84 ×103 tons of steel content in it.

Copper, which is utilized in the junction box, electrical cables, and solar cells, constitutes about 1.90% of the module’s weight. The junction box and cables alone account for 37.09 × 103 tons of copper, while the solar cell contributes 38.84 ×103 tons, totaling 75.93 × 103 tons of copper used in PV modules.

Silver represents 0.12% of the overall weight of a PV module.

The researchers found that total revenue of INR 284.48 billion (around $3.47 billion), INR 408.67 billion, and INR 435.40 billion is possible if the projected waste is recycled through baseline, thermos-chemical, and delamination procedures, respectively.

The research paper is published in ‘Sustainable Energy Technologies and Assessments’ journal by Elsevier.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.