From pv magazine Global

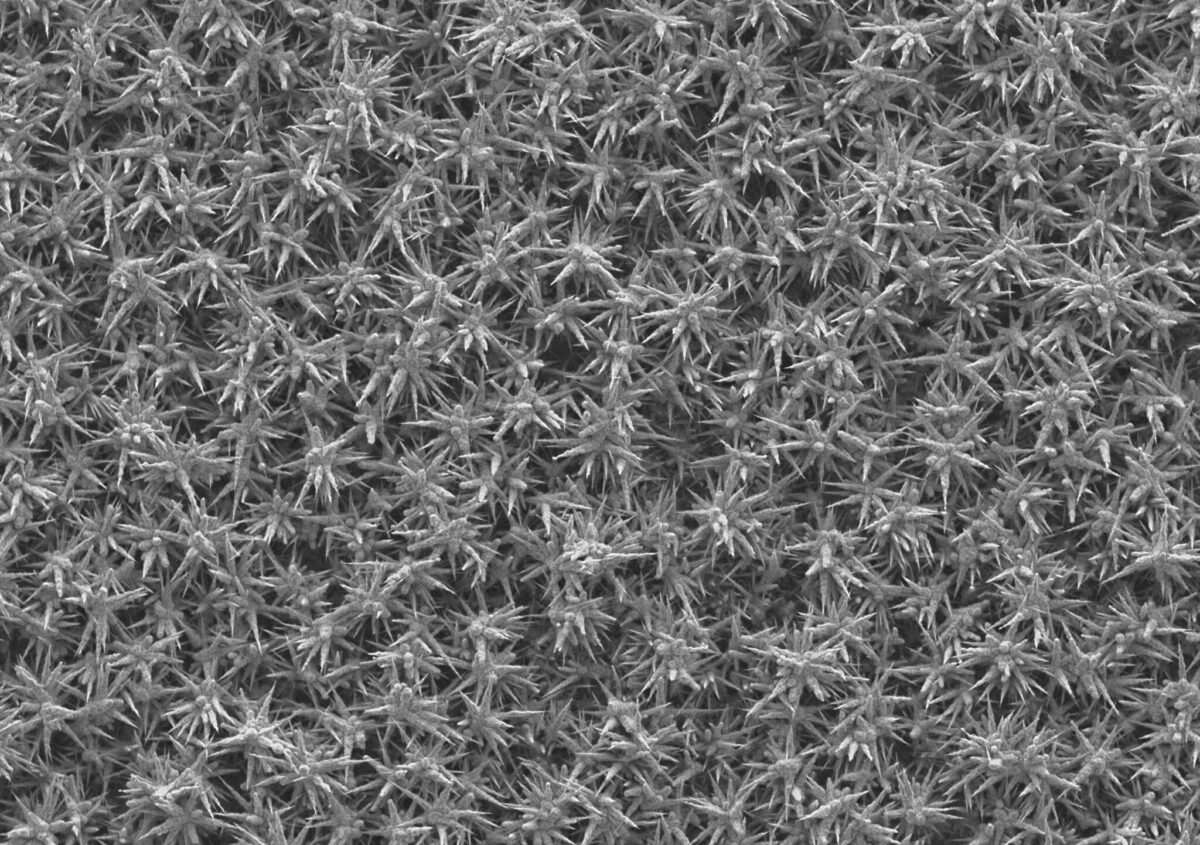

Oxford nanoSystems (OnS), a materials technology company, has claimed that its nanoFLUX metallic-alloy coating significantly improves hydrogen production capacity in alkaline electrolyzers by more than 50%. The proprietary coating, which promotes the formation and release of gas bubbles, enhances process efficiency and reduces production costs. An independent assessment by E4Tech has confirmed the cost-benefit advantage. OnS is collaborating with leading electrolyzer manufacturers to test and scale up nanoFLUX production, in order to reduce green hydrogen production costs, according to OnS CEO Ian Russell.

Denso has revealed plans to launch a pilot program at its Hirose plant in July with a solid oxide electrolysis cell (SOEC) to produce green hydrogen by electrolyzing high-temperature steam. Denso said that the trial will involve testing the green hydrogen in a prototype power card line at its semiconductor manufacturing plant, serving as a verification of SOEC technology and its application in manufacturing.

The Indian government has said that it actively developing a definition for green hydrogen as part of its plans to shape its hydrogen strategy during a three-day conference in New Delhi, starting on July 5. Indian Minister of Renewable Energy Shri Bhalla said there have been around 48 publicly announced projects on green hydrogen in India. He noted the industry’s strong interest in the green hydrogen opportunity, particularly in relation to green ammonia production, which could yield approximately 3.5 million metric tonnes per year of green hydrogen.

Germany and South Africa have agreed to expand cooperation on green hydrogen and power-to-X products. “Our commitment in this area complements the German government’s efforts to support South Africa in its overall energy transition,” said Vice Chancellor Robert Habeck. “To this end, we want to make an additional €30 million ($32.5 million) available from the International Climate Initiative.” The two countries said they aim to cooperate even more closely in producing, processing, and transporting green hydrogen.

Gasunie has announced a planned €100 million investment in the construction of the initial segment of a hydrogen network in the Netherlands. Construction will start in Rotterdam after the summer. The Dutch transmission system operator (TSO) said that the €1.5 billion, nationwide hydrogen network will connect key industrial regions in the Netherlands and neighboring countries, including Germany and Belgium, from 2030. The network will facilitate connections between import terminals, domestic hydrogen production sites, and large-scale hydrogen storage facilities.

H2 Green Steel and Swedish shipping company Gotland Company have agreed to explore the possibility of establishing a production plant that could supply part of Gotland’s fleet with green hydrogen. “H2GS will, in a few years, operate one of the world’s largest electrolyzers in Boden in northern Sweden, with a capacity of over 700 MW,” said H2 Green Steel.

Airbus UpNext has launched a new program to investigate the use of hydrogen fuel cells to generate non-propulsive energy in aircraft. The focus is on the auxiliary power unit (APU), which powers various non-propulsive functions. The company said it plans to replace the APU of an A330 with a HyPower hydrogen fuel cell system in order to reduce CO2 emissions, nitrogen oxides (NOx), and noise levels associated with traditional APUs. In addition, Airbus is conducting tests on a hydrogen conditioning system for supplying aeronautical gas turbines.

Air Liquide and Iveco Group recently reaffirmed their commitment to hydrogen at the inauguration of the first high-pressure hydrogen station (1 ton/day) for long-haul trucks in Europe, in Fos-sur-Mer, France. “This transport solution for long haulage features a fast refueling time at 700-bar pressure,” said Air Liquide. Iveco plans to deliver hydrogen trucks from later this year.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.