Recent hailstorms in Europe and North America have damaged several PV installations and heated up the debate on how solar power generators can be protected by these unpredictable events. A study conducted by Dutch scientists in 2019 showed that damages to solar panels are primarily caused by hailstones measuring at least 3 cm in size.

A new study from India claims now that the typical front glass used for solar panels, with a thickness of up to 3.2 mm, may not be sufficient to protect the modules in hail-prone areas. According to the scientists, although the PV industry mainly uses panels with that thickness, a front glass of at least 4 mm should be used.

“Hail with a diameter of 20 mm to 30 mm is very critical to solar PV,” corresponding author Nallapaneni Manoj Kumar told pv magazine. “Damage is mainly related to the structure, resulting in a reduction of overall power generation, and in some cases also a drop in the operational lifespan.”

Published in Renewable Energy, “Analysis of the hail impacts on the performance of commercially available photovoltaic modules of varying front glass thickness” suggests that standardized IEC durability tests for hail might not be sufficient, as testing of ice balls greater than 25 mm is only optional.

The group compared three PV modules with different thicknesses to their front glass – 2.8 mm, 3.2 mm, and 4 mm – under various hail sizes, weights, and velocities.

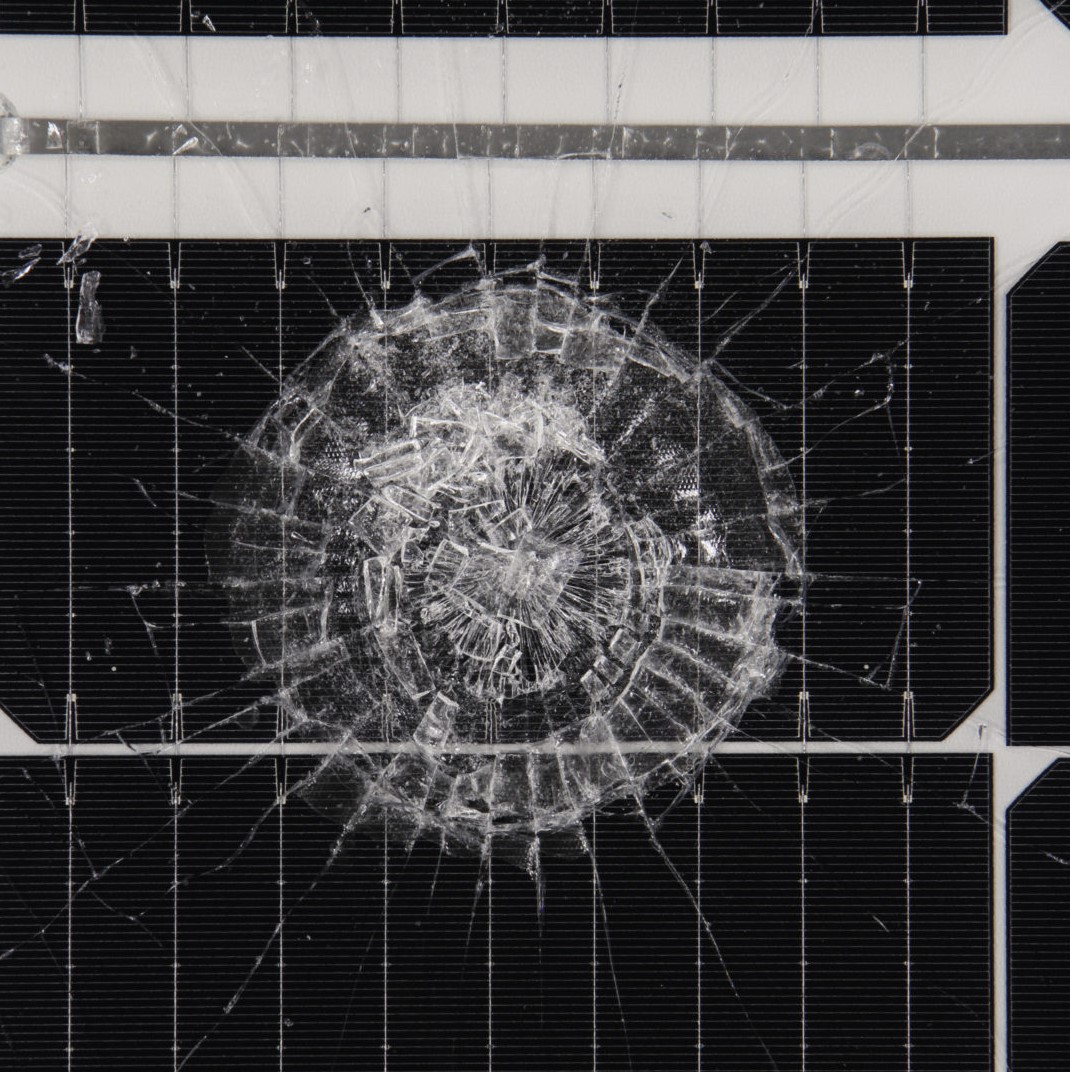

The analysis showed that, after being hit with a 45 mm ice ball, the module with the thinnest glass lost 21.8% of its power output, and the 3.2 mm module lost 11.74%. The thickest module tested lost only 0.81% after being hit with the same size of hail, and when tested against 55 mm hail lost 1.13%. Larger size ice balls were not tested, the scientists said, as they are relatively rare.

The loss of output was due to cracks. “Cracks are frequently imperceptible to the naked eye,” the researchers noted. “They might result in electrically disconnected cell areas, resulting in a linear drop in short-circuit current and increased series resistance, lowering the module’s power output.”

With the 45 mm ball, very severe cracks were visible on the 2.8 mm and the 3.2 mm panels. In the case of the thickest panel, however, only microcracks were found when it was hit with the same-sized ball. “Microcracks can cause an electrical separation, rendering a portion of a cell inactive,” the research team explained.

The academics also ascertained that all three panels experienced wet leakage current resistance – that is, a reduction in their ability to withstand moist and the wet – after being hit with 45 mm hail. The thickest panel lost 27.23% of its resistance, while the medium one lost 46.81%, and the thinnest lost 55.25%.

“The relationship between hail and damage to near-zero emissions measures is fascinating, especially with the likelihood of increased hailstorms owing to climate change in most parts of Europe,” they emphasized. “Because insurers are vigorously offsetting their exposure and module suppliers do not provide a warranty against hail damage, project owners and investors are left to bear the risk.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.