A research group in the Netherlands has fabricated a monolithic perovskite-PERC tandem solar cell that utilizes a new type of tunnel recombination junction (TRJ) based on indium tin oxide (ITO), nickel(II) oxide (NiO), and carbazole (2PACz).

They explained that usually TRJs are based on ITO and 2PACz alone, and that the addition of the NiO layer is intended to reduce electrical shunts in the perovskite top cell, due to the inhomogeneity of the 2PACz layer on ITO.

The group deposited the NiO layer through atomic layer deposition (ALD), which they claim largely improves the uniformity of coverage of the self-assembled monolayer (SAM) of the TRJ.

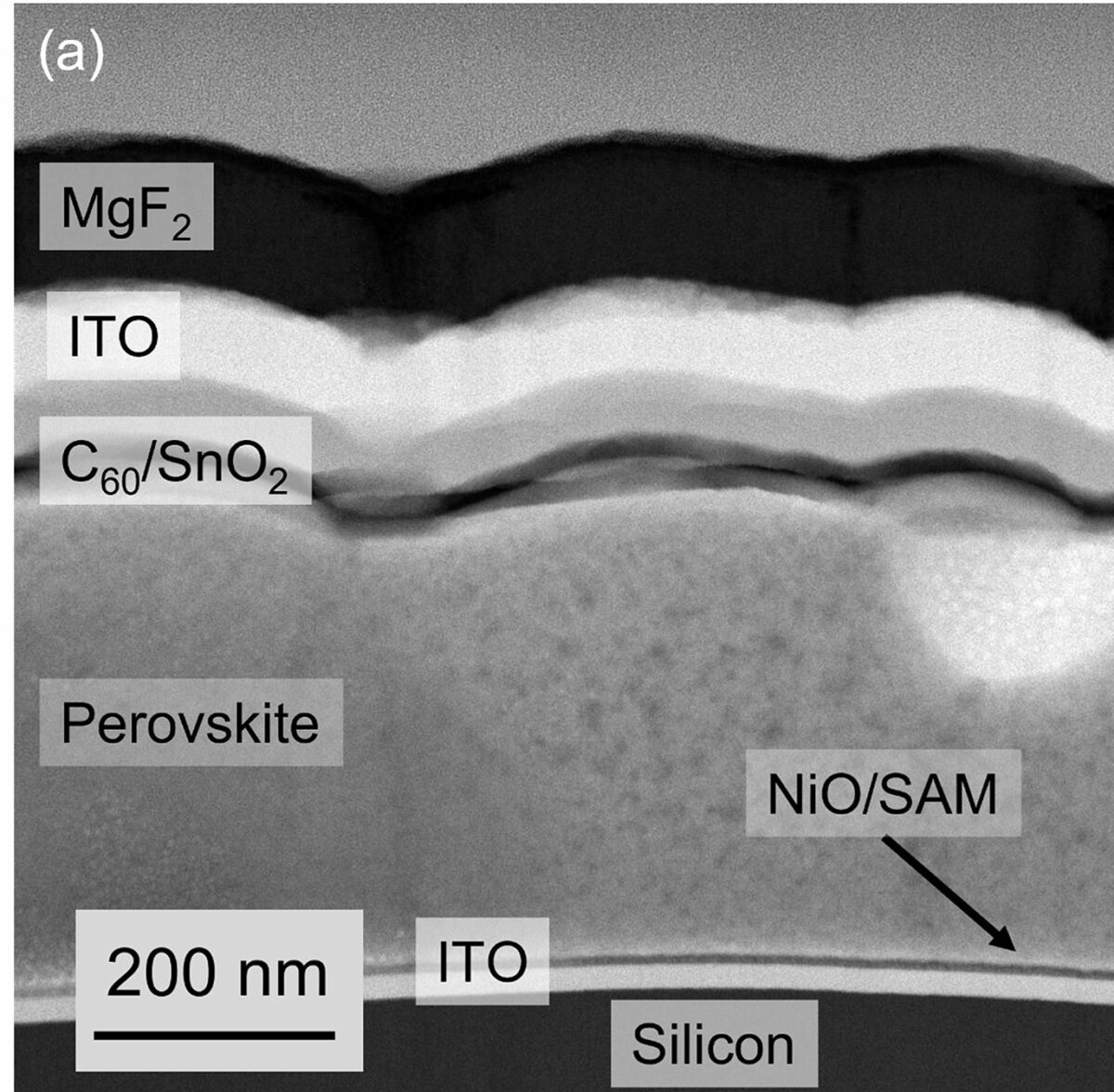

The researchers built the top perovskite cell with the proposed TRJ, a perovskite absorber, an electron transport layer based on buckminsterfullerene (C60) and tin(IV) oxide (SnO2) layer, an ITO electrode, a silver (Ag) metal contact, and an antireflective coating based on magnesium fluoride (MgF2).

“The SnO2 is fabricated on a C60 layer, which is needed to prevent the direct interaction between the ALD precursor and the perovskite layer that can reduce the device performance,” they explained.

The academics tested the performance of the cell under standard illumination conditions and compared it with that of a reference device with a TRJ based only on ITO and 2PACz.

The test showed that the reference cell was able to achieve a power conversion efficiency of 24.2%, an open-circuit voltage of 1.689 V, a short-circuit current density of 18.6 mA/cm2, and a fill factor of 76.9%, while the device based on the novel TRJ reached an efficiency of 23.7%, an open-circuit voltage of 1.705 V, a short-circuit current density of 18.0 mA/cm2, and a fill factor of 77.2%.

The Dutch team explained that, despite the slightly lower efficiency, the cell using the new TRJ technology offers the advantage of the uniform coverage of the SAM and narrower device efficiency distribution, which it said will be highly beneficial when scaling up to larger cell sizes. “When ALD NiO is introduced between ITO and 2PACz, the spread of the device performance decreases, and the cells operate uniformly across different devices within a batch and from batch-to-batch,” it stated.

The solar cell tech is described in the study “Atomic layer deposition of NiO applied in a monolithic perovskite/PERC tandem cell,” published in Solar Energy Materials and Solar Cells. The researchers come from the Eindhoven University of Technology and the Netherlands Organisation for Applied Scientific Research (TNO).

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.