From pv magazine Global

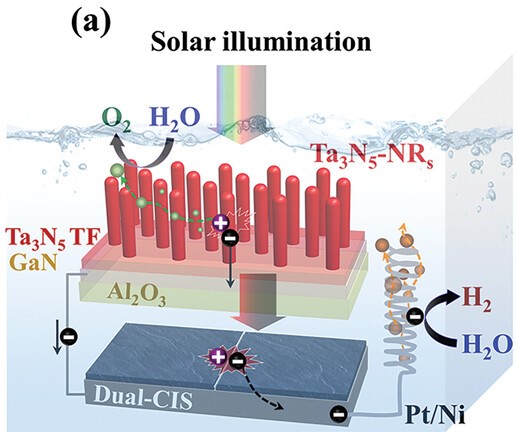

Japanese researchers, led by the University of Tokyo and the Artificial Photosynthetic Chemical Process Technology Research Association (ARPChem), claim to have achieved a solar-to-hydrogen efficiency above 10% in a water-splitting system. They used a photoelectrode with a tantalum nitride nanorod structure and a dual copper-indium-selenium (CuInSe2) solar cell with a platinum-nickel electrocatalyst for hydrogen generation. The system’s tandem configuration achieved a reproducible STH efficiency of approximately 12% – the highest among photocatalytic materials. Although promising for commercialization, the researchers said that further work is needed to enhance the photoanode’s stability and protection.

NewHydrogen has partnered with UC Santa Barbara to research an efficient thermochemical water splitting process for green hydrogen production using heat. CEO Steve Hill noted the cost-effectiveness of renewable heat sources like concentrated solar and geothermal, including waste heat from various industrial processes and power plants.

University of Warwick researchers, in collaboration with scientists from the University of Manchester, have demonstrated the unexpected permeability of graphene to protons, proving that its crystalline structure accelerates proton transport. They outlined their findings in “Proton transport through nanoscale corrugations in two-dimensional crystals,” which was recently published in Nature. They said that their use of scanning electrochemical cell microscopy (SECCM) revealed proton currents accelerated around nanoscale wrinkles, providing greater permeation space through the crystal lattice.

Schmid Group has secured n equipment order from an undisclosed green hydrogen company. The German specialist said it will provide equipment for one of the world’s largest electrolysis factories. Wet chemical plant systems will be supplied under the contract, which is scheduled for installation in the first half of 2024. “The machines play an important role in the production of central components made of stainless steel, which are subsequently assembled into stacks during further processing,” said Schmid Group. “These stacks will in turn be integrated into the electrolysers used to produce green hydrogen.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.