From pv magazine Germany

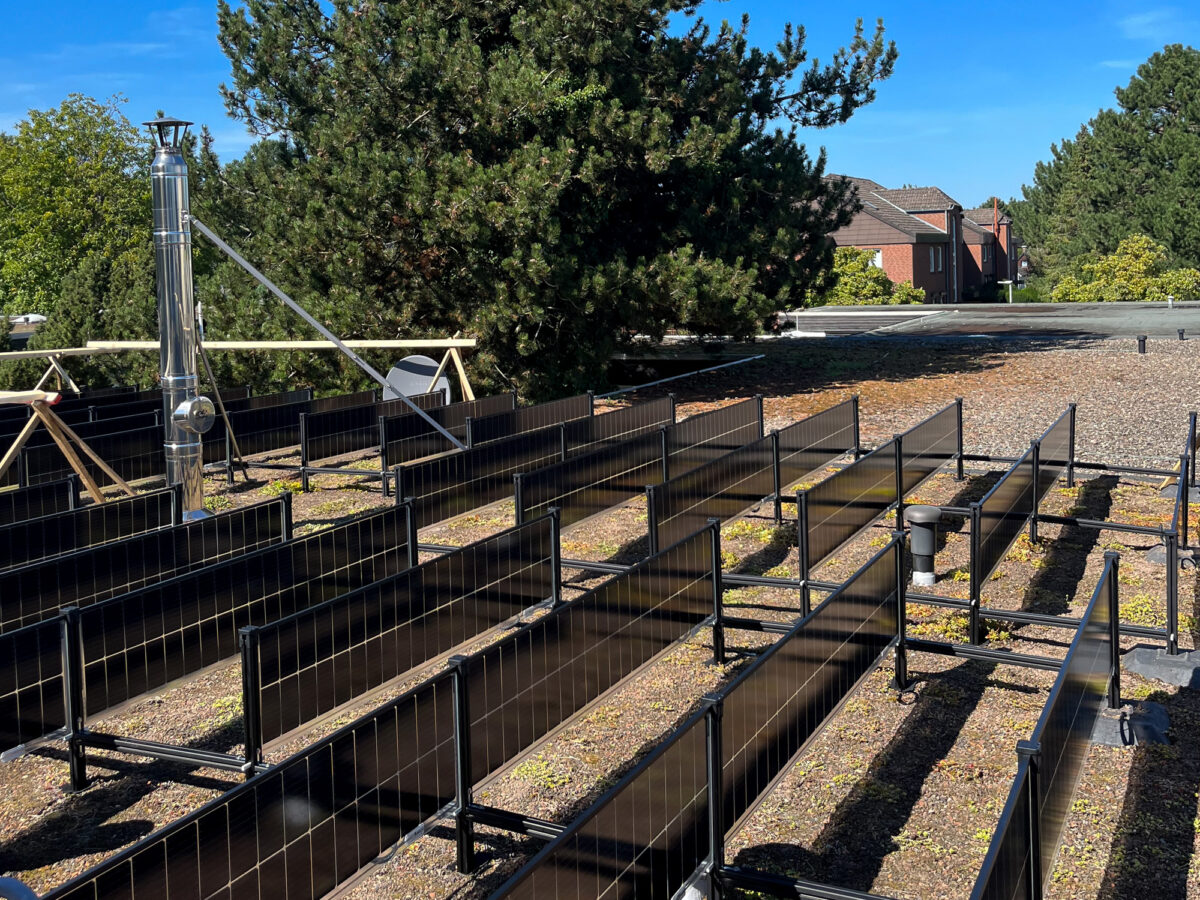

Solyco has deployed its first vertical rooftop PV system at two different locations in Germany.

The Germany-based company described its Solon system as an ideal solution for the residential and commercial flat rooftop market, especially for so-called green roofs, which are rooftops covered with low-maintenance gardens and plants.

One of the two systems is located in Hamburg. The 10 kW project features 68 vertically mounted modules. The second array, in Hannover, includes 79 panels, with a total installed capacity of 12.64 kW.

Both installations have glass-glass bifacial modules made with tunnel oxide passivated contact (TOPCon) cells, installed in a vertical fashion to minimize shadows on the vegetation below. A ballast-supported racking system provides support and avoids drilling into the roof.

The vertical orientation delivers peak power early and late in the day with a valley formed at noon with an east-west orientation, according to the company.

The Solon system relies on frameless custom-designed modules that are smaller than the standard size, measuring 2,011 mm x 415 mm, with a rated power of 160 W. The weight is around 23 kg/m². The panels have 3.2 mm glass sheets front and back with forty-two M10-sized TOPCon cells. The system’s installed nominal capacity is 100W/m², according to the company.

The substructures of the horizontal and vertical aluminum profiles are connected by cross-bracing. Stable connections are secured with a profile connector and bolted with M6 cap screws and safety nuts. The black coating finish on the metal racking and hardware provides the aesthetics reportedly required for this type of application.

Philip Kallenberg, product manager for Solyco, told pv magazine that the main reason it chose TOPCon cells over passivated emitter and rear contact (PERC) cells is because they can reach about “85% bifacial coefficients,” which results in “more balanced energy production” throughout the day.

“A vertical PV system in combination with a green roof is the ideal roofing strategy for any flat roof. It combines the ecological advantages of green roofs with the local production of renewable energy,” Solyco CTO Lars Podlowski told pv magazine.

The company’s wind tunnel test have confirmed that the system does not experience drag or lift forces. According to Kallenberg, wind loads primarily impact the first and last rows of modules, resulting in fewer required ballast blocks compared to traditional horizontal installations.

“Only the first and last row need ballast bases to prevent displacement,” Kallenberg stated.

Recently installed pilot systems in Hannover and Hamburg follow tests of an earlier version of the system at an outdoor location near the company’s headquarters in Berlin. Solyco developed the technology in cooperation with ISC Konstanz, University of Applied Sciences HTW Berlin, and funded by the country’s Federal Ministry for Economic Affairs and Climate Action (BMWK) through its program for SMEs (ZIM).

Solyco sells the systems through distributors and partners, such as Germany-based Optigrün International. Certifications include IEC 61215: 2016, IEC 61730: 2016, and a 25-year product warranty and linear performance guarantee.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.