From pv magazine Global

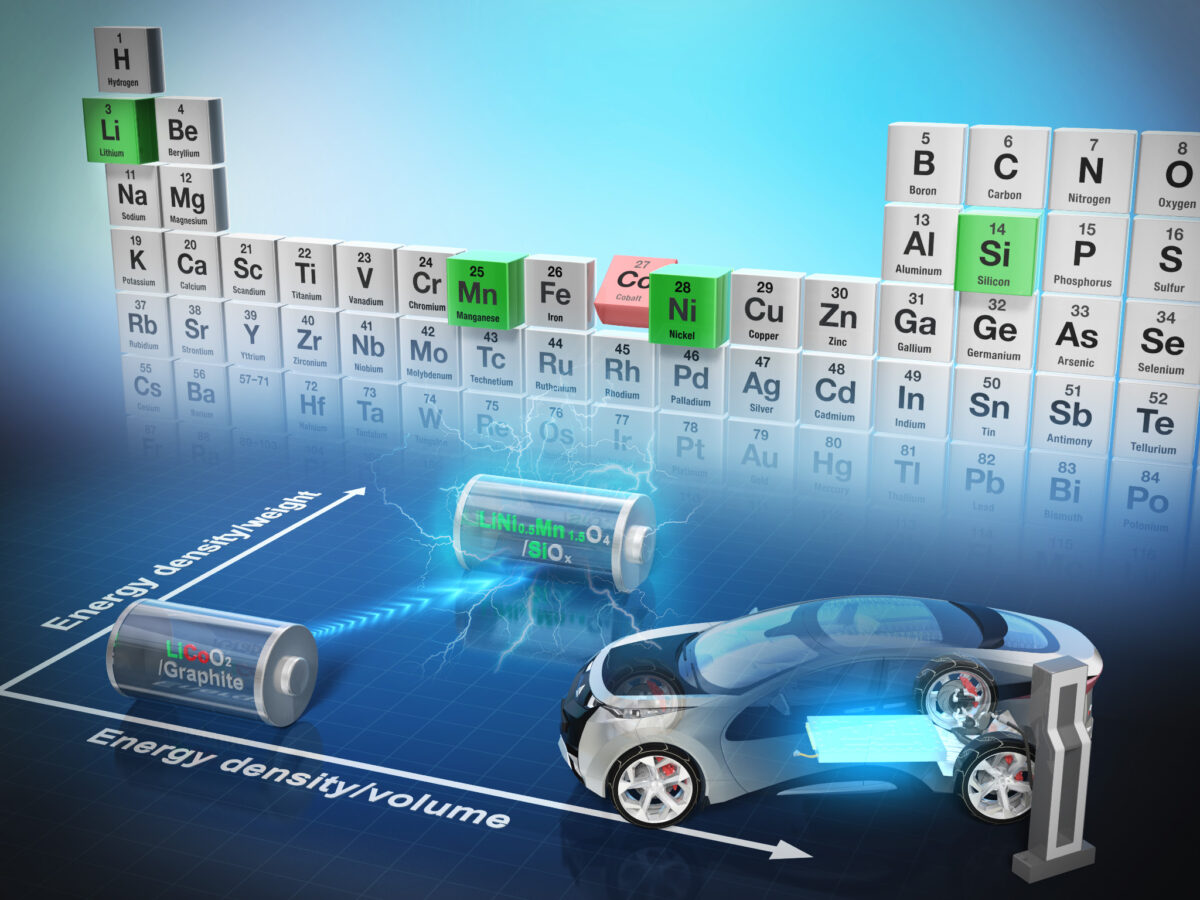

Today’s electric vehicles are predominantly powered by nickel-manganese-cobalt (NMC) lithium-ion batteries. However, the inclusion of cobalt in this type of batteries has been considered as problematic due to its anticipated scarcity as well as associated supply chain risks related to its single source, human rights and mining practices.

Now, a team led by researchers from the University of Tokyo has designed a lithium-ion battery pairing a cobalt-free cathode with a silicon suboxide (SiOx) anode, successfully addressing the cobalt challenge.

“There are many reasons we want to transition away from using cobalt in order to improve lithium-ion batteries,” said Professor Atsuo Yamada from the Department of Chemical System Engineering. “For us the challenge is a technical one, but its impact could be environmental, economic, social and technological. We are pleased to report a new alternative to cobalt by using a novel combination of elements in the electrodes, including lithium, nickel, manganese, silicon and oxygen — all far more common and less problematic elements to produce and work with.”

Underlying this favorable electrode combination is a rational electrolyte design based on 3.4 M LiFSI/FEMC featuring a shifted potential, which serves to aid formation of robust passivation layers on the anode and promote electrolyte stability against both reductive and oxidative degradations.

In addition to featuring electrodes and electrolytes devoid of cobalt, the new battery design has also displayed a number of advantages over conventional lithium-ion batteries. It has an energy density about 60% higher, which could equate to longer life, and it can deliver 4.4 volts, as opposed to about 3.2-3.7 volts of conventional NMC batteries.

In addition, test batteries with the new chemistry were able to fully charge and discharge over 1,000 cycles, simulating three years of full use and charging. In the process, they were losing only about 20% of their storage capacity.

“We are delighted with the results so far, but getting here was not without its challenges. It was a struggle trying to suppress various undesirable reactions that were taking place in early versions of our new battery chemistries which could have drastically reduced the longevity of the batteries,” said Yamada.

“And we still have some way to go, as there are lingering minor reactions to mitigate in order to improve the safety and longevity even further. At present, we are confident that this research will lead to improved batteries for many applications, but some, where extreme durability and lifespan are required, might not be satisfied just yet.”

According to the researchers, their electrolyte formulation offers a pathway towards both sustainable and high-performing lithium-ion batteries, while the concept could be applied to other electrochemical energy technologies, including other kinds of batteries, water splitting (to produce hydrogen and oxygen), ore smelting, electro-coating and more.

Their findings are discussed in “Electrolyte design for lithium-ion batteries with a cobalt-free cathode and silicon oxide anode,” published in Nature Sustainability.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.