With India reinforcing its commitment to become a ‘net-zero’ country by 2070, it is enthusiastically embracing innovative approaches to build a sustainable future. In its quest to meet sustainability goals, the country has pledged to become an EV-first nation by 2030, focusing on expediting the transition to clean transportation.

Here, it is important to understand that Li-ion batteries are at the heart of the EV ecosystem. Hence, as the country marches towards deeper penetration of electric vehicles into the market, there is an incessant need to accelerate the manufacturing of Li-ion batteries to meet the rising demand projected in the market. Owing to this, the recycling of Li-ion batteries has been gaining a lot of traction in recent years.

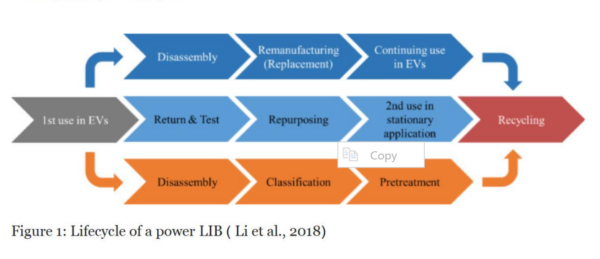

Considering the blowout development of EVs, the disposal of the huge amount of spent lithium-ion batteries (LIBs) brought about by the exhaustion of the life-cycle of LIBs will soon become a huge problem that plagues society.

Recycling end-of-life LIBs can help address this material scarcity by reducing dependence on lithium mining by 25%, and cobalt by 35%. It would also ensure the local availability of recycled critical materials. Lithium has very limited availability on the earth. Therefore, we need to “Look Beyond Mines” and save this precious metal for our next generations.

Battery recycling plays an imperative role in achieving a two-fold purpose. On one hand, it can give the desired impetus to the expansion of the EV industry, on the other hand, it can immensely contribute to curbing the impact on the environment due to the manufacturing of new batteries. Therefore, industry players are invariably working towards upscaling their recycling capacity to be at par with the evolving battery technologies.

To further fortify the recycling of Li-ion batteries, it is very important to closely monitor the external conditions where the temperature and high humidity can immensely meddle with the recycling prospects of the battery. Therefore, to ensure effective recycling of Li-ion batteries, industry players should install dehumidifiers to curb the moisture menace throughout the process.

Cathode dismantling forms an intricate part of battery recycling. To initiate the process, NMP is used as an important organic solvent to facilitate the recovery of the metal. But in the presence of moisture, NMP becomes inherently hazardous which can severely impact the environment and give rise to serious health issues like cancer. At the same time, during the dismantling process, hydroxide is released, which, on coming in contact with moisture, creates hydrogen. Understanding that hydrogen is highly inflammable in nature, even a small spark can trigger blasting of the space.

Furthermore, weather condition disruption can deteriorate the powder form of extracted components via humidification and/or oxidation through moisture in the air. This will finally affect the quality of recycled metals. Therefore, deploying desiccant dehumidifiers is essential to conduct battery recycling in a highly controlled environment.

Deciphering the importance of Li-ion battery recycling, let’s look at the different ways to recycle batteries.

Hydrometallurgy

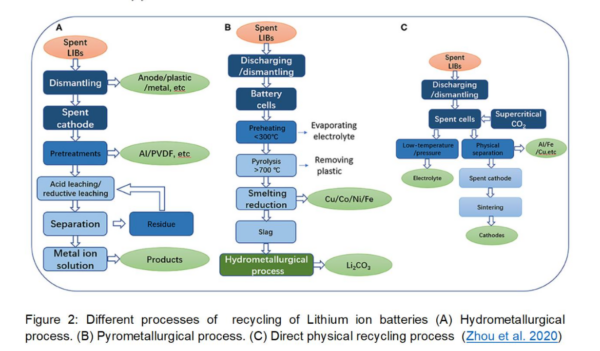

Hydrometallurgy is majorly involved in breaking down the battery into powder of black mass. It is an extractive metallurgy process that uses aqueous solutions to recover metals. The technique chemically dissolves or leaches materials to extract metals by means of precipitation or electrically reducing the metals. The process is followed by leaching with acid to extract metal in an aqueous solution. The solution is then purified and refined to concentrate and separate metals from the materials.

Pyrometallurgy

Pyrometallurgy employs heating and smelting operations to perform the separation of the metal. It melts the materials used to extract metals. In such processes, a high temperature is maintained to enable oxidation and reduction reactions for initiating the reduction of metal from oxides. The method involves calcination where lithium is extracted by burning batteries. The ashes produced as a result are further removed in the subsequent processes.

There is an alternate method as well, in which roasting, or oxidation roasting is done where a reaction with metal-bearing components is carried out for transformation to metal oxides that can be later dissolved and extracted by leaching. Here, crushing and grounding are done before leaching out oxidized base metals that leave behind a residue that is rich in precious metal.

Direct Recycling

This is a physical process where different components of the black mass are separated with the help of gravity separation. This is an efficient method for recovering separated materials, that too without causing any chemical changes. In the process, it enables recovery of cathode material which can be used with minimal treatment.

Membrane Separation

The method employs electrodialysis to transport dissociated ions across semi-selective ion-exchange membrane pairs that are placed between two electrodes. Here, the primary electrodialysis cell is made up of anion-and cation-exchange membrane that is separated by a partition allowing the free flow of solutions. The diffusion of cations through the cation exchange membrane towards a negatively charged cathode accumulates in the anion exchange membrane. In turn, developing valence or size-selective ion exchange membranes helps in recovering valuable metals of smaller size.

Carbothermal Treatment

Carbothermal reduction is used as an alternative to overcome technical demerits in the pyrometallurgical process. The method recovers metal by using graphite as a reductant in the carbothermal reaction. It promotes the formation of metal rather than enabling conversion to metal oxides. This immensely increases the recovery yield of metals.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.