A group of researchers led by the University of North Carolina at Chapel Hill has developed new mini solar modules based on perovskite cells treated with zinc trifluoromethane sulfonate [Zn(OOSCF3)2].

“This low-cost material is used as an additive at a very small percentage into perovskite ink,” the research’s lead author, Jinsong Huang, told pv magazine. “Its use makes perovskite modules cheaper because it makes the fabrication much more reproducible.

Huang also explained that nonuniformity in perovskite films arises from oxidized perovskite inks, especially oxidation of iodide to molecular iodine when inks are exposed to an ambient environment during the fabrication process. In addition, the introduction of 2D-iodide salts in the perovskite inks introduces more iodide interstitials. “Both molecular iodine generation in inks and many iodide interstitials in the perovskite films present nonuniformity in perovskite films and thus lead to larger cell-to-module efficiency,” he added.

The researchers added five different zinc salts into five samples of perovskite ink, and fabricated small solar cells via a blade coating process. The different zinc formations were zinc formate [Zn(OOCH)2], zinc acetate [Zn(OOCCH3)2], zinc trifluoroacetate [Zn(OOCCF3)2], zinc trifluoromethane sulfinate [Zn(OOSCF3)2], and zinc trifluoromethane sulfonate [Zn(OO2SCF3)2]. They also fabricated a reference cell without the addition of zink.

In addition, each cell was tested with different additive concentrations of 0.14%, 0.28%, 0.42%, and 0.55%. On the cell level, the scientists found the Zn(OOSCF3)2 with a concentration of 0.28% to deliver the best results, with an average open circuit voltage of 1.18 V and a fill factor of 82%. This compares with an open-circuit voltage of 1.16 V and a fill factor of 80% in the control cell.

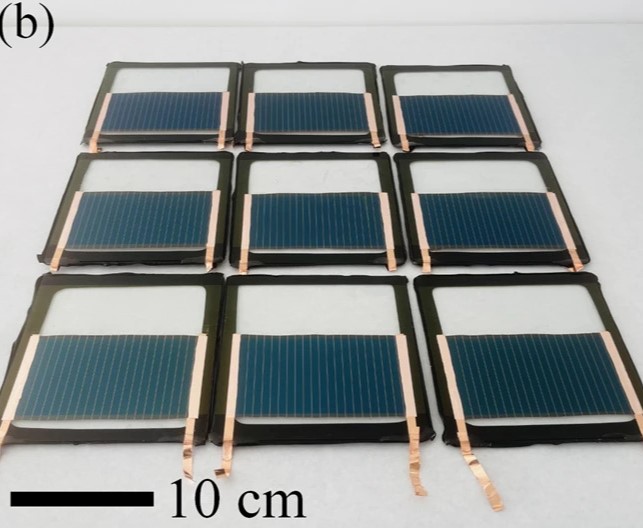

Image: University of North Carolina at Chapel Hill, Nature Communications, CC BY 4.0 DEED

“The results indicate that Zn(OOSCF3)2 improves the device efficiency through defect passivation as both open-circuit voltage and fill factor are significantly enhanced,” said the researchers.

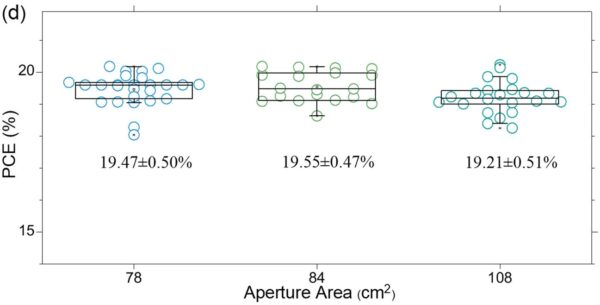

They then used the Zn(OOSCF3)2 at the optimized concentration to blade coat 78 cm2 of perovskite films, from which they fabricated mini modules with an area of 78 cm2, 84 cm2, and 108 cm2, respectively. They all had 20 sub-cells, each with a width of 6.5 mm.

“Fabricated minimodules show power conversion efficiencies of 19.60% and 19.21% with aperture areas of 84 cm2 and 108 cm2, respectively, as certified by National Renewable Energy Laboratory (NREL),” the results showed. “That is the highest efficiency certified for minimodules of these sizes.”

Conducting further investigation into the minimodules’ optoelectronic and morphologic properties, the academics emphasized that Zn(OOSCF3)2 passivated the defects of the perovskites despite its induction of negligible grain size changes. “The CF3SOO‒ anions can reduce the generated iodine during perovskite solution or device aging. At the same time, the zinc cations can precipitate the excess iodide so that the iodide interstitial concentration is diminished throughout the films, resulting in improved device efficiency and stability,” they explained.

The scientists displayed their results in “Iodide manipulation using zinc additives for efficient perovskite solar minimodules,” published in Nature Communications. “To be commercialized, it needs to be applied to equipment that can handle bigger size modules, such as slot-die coater, or roll-to-roll coaters,” Huang concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.