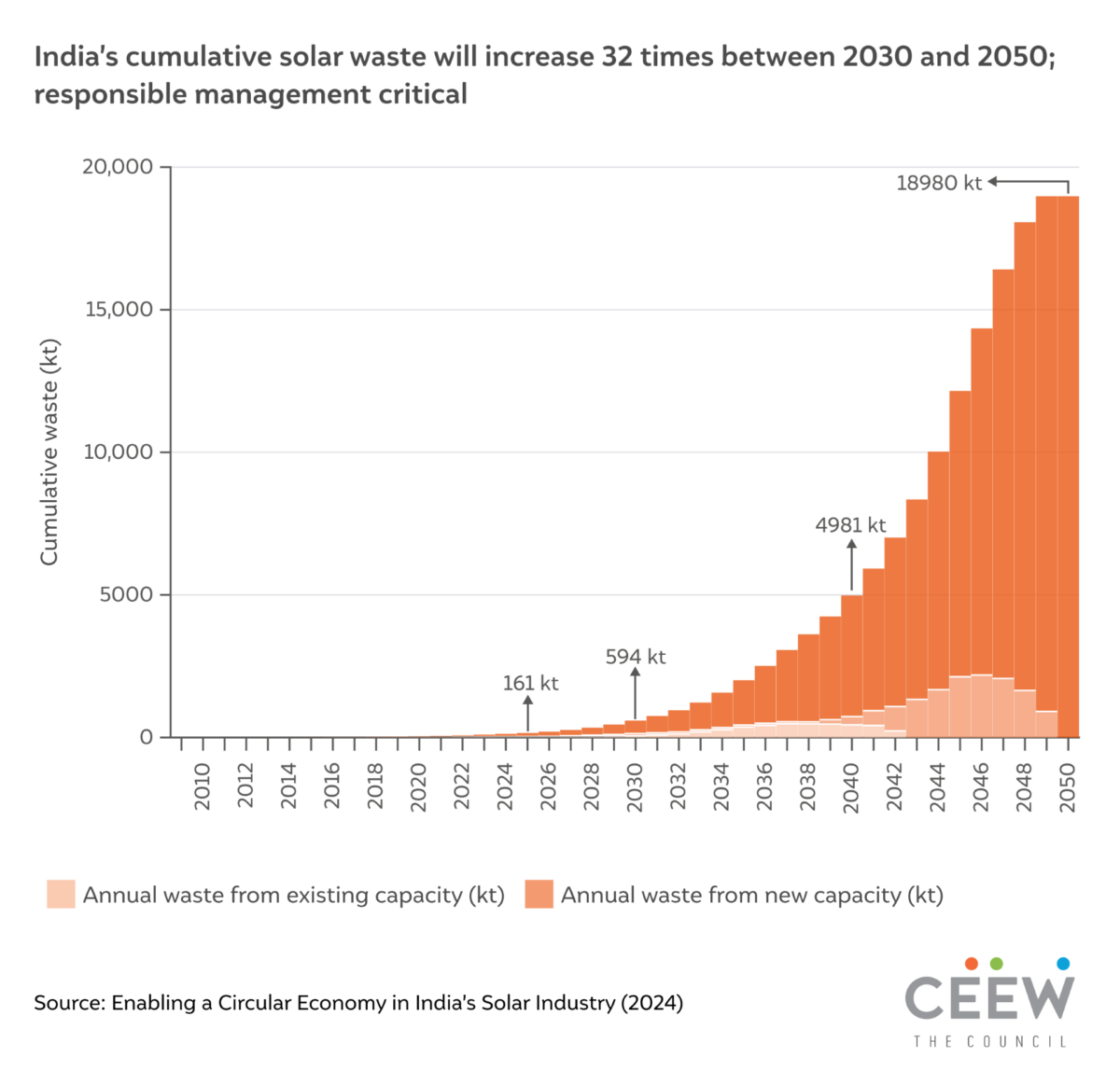

India’s cumulative solar PV waste will reach about 19,000 kilotonnes (kt) by 2050 as all the capacity deployed until 2030 will have reached end of life, according to a new study by the Council on Energy, Environment and Water (CEEW) which estimates India-specific solar waste generation from various streams, excluding manufacturing.

The report states while the modules are designed for a 25-year life, some witness an early end of life due to factors such as damage during transportation, module handling, and project operations.

According to the report, India’s installed 66.7 GW capacity, as of FY 2023, has generated about 100 kt of waste, which will increase to 340 kt by 2030. The 340 kt of waste is estimated to contain about 10 kilotonnes of silicon, 12-18 tonnes of silver, and 16 tonnes of cadmium and tellurium—the majority of which are critical minerals for India. Around 67% of the 340 kt solar waste will be generated in five states: Rajasthan, Gujarat, Karnataka, Andhra Pradesh, and Tamil Nadu.

The cumulative solar waste from the existing and new PV capacity deployed between FY24 and FY30 will reach about 600 kt by 2030, equivalent to filling up 720 Olympic-size swimming pools.

The study authors assumed India’s installed PV capacity would reach about 292 GW by 2030. Furthermore, India would need about 1,700 GW of solar capacity by 2050 and 5,600 GW by 2070 to achieve its 2070 net-zero target.

The study authors say the mounting solar waste presents an opportunity for India to emerge as a leading hub of circular economy for the solar industry and ensure resilient solar supply chains.

India is already implementing several measures to tackle the waste. Last year, the Ministry of Environment, Forest and Climate Change (MoEFCC) issued E-waste Management Rules 2022 that shall govern the management of solar PV cells and modules waste in India. These rules mandate the producers of solar cells and modules to manage their waste under the extended producer responsibility (EPR) framework.

Dr Arunabha Ghosh, CEO, CEEW, said, “India must proactively address solar waste, not just as an environmental imperative but as a strategic necessity for ensuring energy security and building a circular economy. As we witness the remarkable growth of solar from only 4 GW in March 2015 to 73 GW in December 2023, robust recycling mechanisms become increasingly crucial. They safeguard renewable ecosystems, create green jobs, enhance mineral security, foster innovation, and build resilient, circular supply chains.”

Neeraj Kuldeep, Senior Programme Lead, CEEW, added, “India’s G20 Presidency had identified a circular economy as a thrust area for sustainable development. A circular solar industry and responsible waste management will maximise resource efficiency and make domestic supply chains resilient. The CEEW study provides robust evidence of the opportunity in solar waste management. However, solar recycling technologies and the industry are still at a nascent stage and require policy push and support.”

The CEEW study recommends that the Indian solar industry prepare for new responsibilities by arranging reverse logistics, storage, dismantling centres, and recycling facilities. The industry should also explore innovative financing mechanisms and business models for solar waste management. Further, there should be a periodically updated database of the installed solar capacity (containing details such as module technology, manufacturer, and commissioning date) to accurately map plausible waste generation centres and strategic deployment of waste management infrastructure.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.