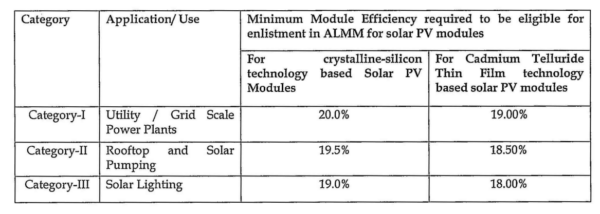

The Ministry of New and Renewable Energy has set minimum efficiency requirements for Cadmium Telluride (CdTe) thin-film technology based solar modules to qualify for inclusion on the Approved List of Models and Manufacturers (ALMM). The minimum efficiency requirements for crystalline-silicon technology based solar PV modules were already notified by the MNRE in May 2023.

As per the notification, the minimum module efficiencies for ALMM enlistment across large-scale (utility-scale), rooftop solar and solar lighting applications are as follows:

Source: MNRE

The ALMM [Approved List of Models and Manufacturers] mandate, reimposed from April 1, 2024, requires solar projects awarded by central nodal agencies and state distribution utilities to source PV modules only from the manufacturers included in the ALMM list. The list currently comprises only domestic solar OEMs and includes modules with an efficiency equal to or greater than 19%.

Currently, CdTe modules are manufactured by Arizona-based First Solar, which has also set up a 3.3 GW manufacturing facility in India. The facility is now operational.

First Solar has repeatedly produced efficiency-record breaking CdTe research cells since 2013, and brought CdTe to a level of maturity, in terms of products, factory productivity, reliability, and environmental performance, to be able to reach scale—in comparison to other thin-film technologies, featuring copper, indium, and selenium (CIS) and copper, indium, gallium, and selenide (CIGS), which are still addressing niche or emerging applications.

First Solar CdTe thin-film modules have among the lowest carbon and water footprint of any commercially available PV module today.

Regarding the efficiency requirement for crystalline-silicon technology based solar PV modules, Akshay Mittal, director at Bluebird Solar, said, “The MNRE directive mandating a minimum [c-Si] module efficiency of 20% for utility-scale photovoltaic (PV) projects serves as a catalyst for innovation and technological advancement within the industry. One of the keys to meeting the MNRE’s efficiency requirements lies in offering advanced technologies such as half-cut mono facial and bifacial modules, along with more sophisticated TOPCon (Tunnel Oxide Passivated Contact) panels. These technologies offer higher efficiency levels, with module efficiencies exceeding 22%. By embracing these cutting-edge solutions, manufacturers can not only meet the mandated efficiency standards but also enhance their competitiveness in the dynamic solar PV market landscape.”

Under the MNRE directive, c-Si modules with efficiencies of 19.5% and 19% are eligible for rooftop and solar water pumping installations, and solar lighting projects, respectively. “With PM Suryaghar Muftbijli Yojana and PM Kusum Yojana in place, PV modules below 20% efficiency can be effectively utilized in various rooftop and other solar applications, thus maximizing their contribution to rural electrification and agricultural sustainability,” said Mittal.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.