Solar Energy Corp. of India (SECI) has extended bidding for setting up 1.5 GW of electrolyzer manufacturing capacity in India under the second round of the government’s Strategic Interventions for Green Hydrogen Transition (SIGHT) program. The revised deadline now stands at May 31.

Bidders setting up electrolyzer manufacturing facilities under this program will be eligible for government incentives provided they meet the qualification criteria as laid out in the tender document.

SECI has been appointed as the implementing agency for the incentive scheme for electrolyzer manufacturing.

Out of the total 1.5 GW capacity, 1.1 GW is tendered for electrolyzer manufacturing capacity based on any stack technology, 300 MW for electrolyzer manufacturing capacity based on indigenously developed stack technology, and 100 MW for electrolyzer manufacturing capacity based on indigenously developed stack technology-smaller units. The minimum/maximum bid capacities for these three categories are 100 MW/300 MW, 100 MW/300 MW and 10 MW/30 MW, respectively.

To be eligible for incentives under this scheme, the electrolyzer manufacturer must commit to fulfilling certain values of electrolyzers performance and local value addition. The electrolyzer’s specific energy consumption (σ) should be equal to or less than 56 kWh/kg of H2 production. For alkaline electrolyzers, local value addition should be a minimum of 40% in the first year and at least 80% by the fifth year. For proton exchange membrane, solid-oxide, and anion exchange membrane electrolyzers, the local value addition should be a minimum of 30% in the first year and at least 70% by the fifth year. The guaranteed life of electrolyzer shall be at least 60,000 hrs with end-of-life efficiency not falling below 80%.

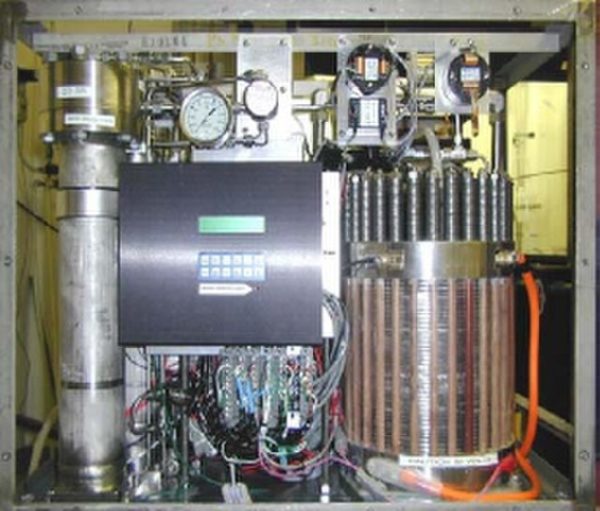

Asahi Kasei and partners celebrated the official opening of a new hydrogen pilot plant in Kawasaki, Japan. The commercial-scale facility will test its alkaline water electrolyzer, which is optimized for the production of green hydrogen. “The trial operation of four 0.8 MW modules is another milestone toward the realization of a commercial multi-module 100 MW-class alkaline water electrolysis system for green hydrogen production,” said the Japanese company in an emailed note.

China Aerospace Science and Technology Corp. (CASC) has developed China’s first 100 kg, vehicle-mounted liquid hydrogen system. The system will allow hydrogen-powered heavy trucks to achieve a range of more than 1,000 km with just one charge. “Compared to its predecessor, the system boasts a 20% increase in effective volume within the same overall dimensions while cutting costs by more than 30%,” said CASC.

New Mexico Governor Michelle Lujan Grisham is in Rotterdam for the 2024 World Hydrogen Summit to convince manufacturing companies to invest in the US state. “We’ve created an incredible hydrogen policy landscape in our state that is supportive on the supply side and demand side, and global energy leaders are taking notice,” said Lujan Grisham in a press release.

Nikola has opened its latest HYLA high-pressure modular refueling station and facility in southern California. “This launch is yet another pivotal milestone in Nikola’s strategic plan, aiming to establish a network of up to nine refueling solutions by mid-2024, with a total of 14 operational sites slated for completion by year-end, which include a combination of HYLA modular fuelers and partner stations such as FirstElement Fuels’ in the Port of Oakland,” said the company.

Fortescue has started developing a $550 million green hydrogen production venture in the United States. It is the first of the Australian company’s planned green energy investments in North America. “The US has made serious strides in attracting global investment in green hydrogen and decarbonization projects, like Fortescue’s solar and wind-powered Arizona Hydrogen facility,” said Fortescue Executive Chair and Founder Andrew Forrest, arguing that the US government has to further support the hydrogen sector.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.