A Chinese-Canadian research group has designed a monolithic all-perovskite tandem solar cell that utilizes a top inverted perovskite PV device based on an absorber made with mixed tin-lead (Sn-Pb) perovskite via a newly developed thermal regulation strategy.

Inverted perovskite cells have a device structure known as “p-i-n”, in which hole-selective contact p is at the bottom of intrinsic perovskite layer i with electron transport layer n at the top. Conventional halide perovskite cells have the same structure but reversed – a “n-i-p” layout. In n-i-p architecture, the solar cell is illuminated through the electron-transport layer (ETL) side; in the p-i-n structure, it is illuminated through the hole‐transport layer (HTL) surface.

The scientists said their approach consisted of improving the thermal stability and facile oxidation of Sn by incorporating carboranes in the perovskite material. These compounds, which are also known as dicarba-closo-dodecaboranes, are electron-delocalized clusters composed of boron, carbon, and hydrogen atoms with heat transfer capabilities.

“Carboranes are electron-delocalized carbon–boron molecules with significant overlap between atomic orbitals of neighboring atoms, allowing electrons to move freely, and spread out over a larger region within the materials,” they stated. “The characteristic of electron delocalization enables them to improve thermal conductivity and efficient carrier transport.”

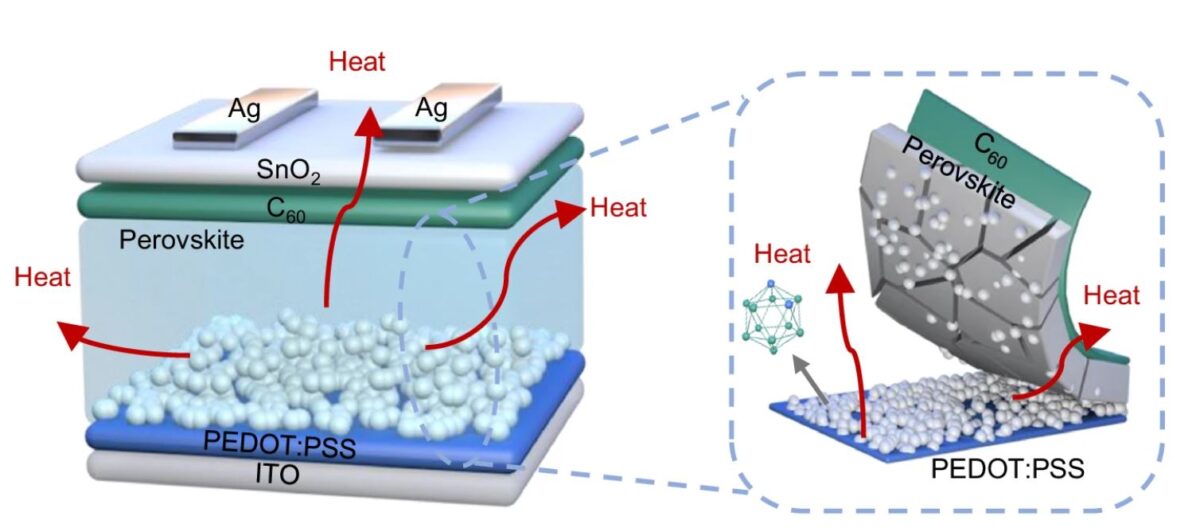

The group selected a carborane type known as ortho-carborane (o-CB, C2B10H12) and said it has “exceptional” heat transfer ability and chemical stability. It was placed in the cell to prevent direct contact between the perovskite and the PEDOT: PSS layer (HTL) to suppress degradation at elevated temperatures.

The top solar cell was built with a substrate made of indium tin oxide (ITO), a hole transport layer (HTL) relying on PEDOT:PSS, the perovskite absorber, an electron transport layer (ETL) relying on buckminsterfullerene (C60), a tin oxide (SnO2) buffer layer, and a silver (Ag) metal contact.

Through density functional theory (DFT) calculations, the academics found that ortho-carborane and perovskite could stably combine, and that further ultraviolet photoelectron spectroscopy (UPS) measurements confirmed the improved interfacial energy level of the absorber.

“The valence band maximum of a perovskite film shifted from –5.42 to –5.31 eV after ortho-carborane treatment, making its band offset with the highest occupied molecular orbital of PEDOT:PSS smaller and reducing interfacial recombination,” they explained.

A champion solar cell built with this configuration achieved a power conversion efficiency of 23.4%, an open-circuit voltage of 0.877 V, a short-circuit current density of 32.19 mA cm2, and a fill factor of 82.9%. The device was also found to retain 90% of its initial efficiency after 1,000 h. For comparison, a cell without the carborane treatment retained only 62% of its original efficiency after 400 h.

The cell was then integrated as a top device in a monolithically integrated all-perovskite solar cell based on bottom cells made of Sn-Pb perovskite. The tandem cell was able to achieve a 27.2% efficiency, an open-circuit voltage of 2.16 V, a short-circuit current density of 15.6 mA/cm2, and a fill factor of 81%.

“We further tested the stability of the encapsulated tandem solar cells under simulated one-sun illumination at MPP,” the group said.” The pristine tandem retained 87% of its initial efficiency after 704 h of continuous operation.”

The new solar cell concept was introduced in the study “Sustainable thermal regulation improves stability and efficiency in all-perovskite tandem solar cells,” which was recently published in Scientific Reports. The research team included academics from the University of Toronto in Canada and the Qingdao University of Science and Technology in China.

Another research group at the University of Toronto recently unveiled a 25.1%-efficient all-perovskite triple-junction solar cell that reportedly shows improved homogenization of the halide perovskite film.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.