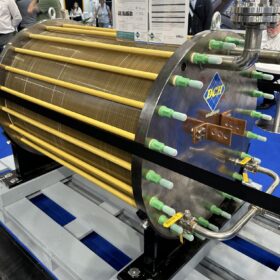

UIS Technologies, Malaysia, a precision technology company based in Penang, Malaysia, has announced the commissioning of its polyurethane (PU) recoating and regrooving solutions for wire guide rollers (WGRs) at Adani’s 2 GW solar ingot-wafer facility in Mundra, Gujarat.

WGRs play a crucial role in the ingot slicing stage of silicon ingot to wafer manufacturing processes. The precision grooving of these rollers significantly affects the shape and thickness of the silicon wafer, with even minor deviations potentially impacting solar cell efficiency. Given the continuous nature of this process, wear and tear results in deteriorating precision of the grooving teeth and pitch of WGRs over time.

Manufacturers are faced with the choice of investing in new WGRs or opting for recoating and regrooving to extend their lifespan. UIS Technologies, Malaysia offers a turnkey solution for recoating and reprocessing WGRs at the plant site with complete knowledge transfer to plant engineers so they can independently utilize the solution in the long run. This means no costly overseas transit of the equipment.

UIS Technologies has been providing these solutions to global silicon wafer manufacturers for a long time.

CT Teh, managing director of UIS Technologies, said, “The PU recoating and regrooving can maintain optimal performance for up to 8-10 years. Following each regrooving process, WGRs are capable of performing 80 to 120 cuts, depending on the slicing speed at the plant.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.