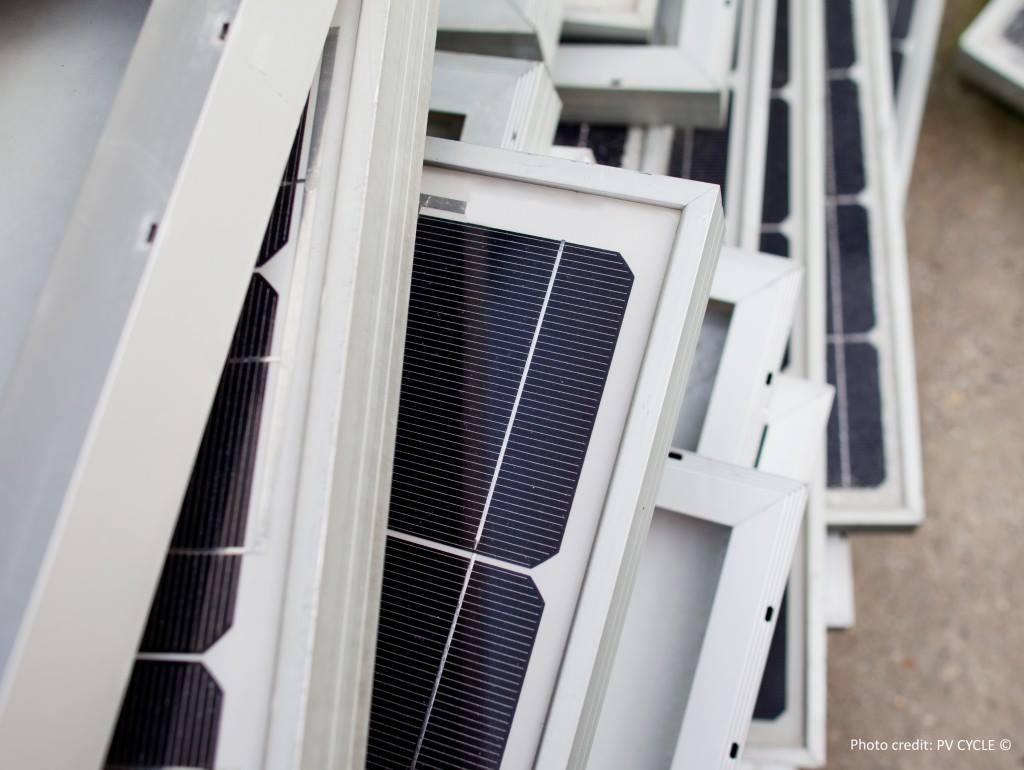

A new report from the International Energy Agency’s Photovoltaic Power Systems Programme (IEA-PVPS) describes the growth in dedicated end-of-life solar PV recycling activity, providing an overview of equipment manufacturers and recyclers, as well as trend information about patents and research publications. It also provides some early life cycle inventory (LCI) information provided by several commercial recyclers in the U.S. and Europe.

The report includes details about 177 commercial PV material recyclers and equipment providers, up from 25 companies identified in a 2017 study. “It is exciting to see the progress over a roughly 6-year period in the number of recycling companies with dedicated PV solutions since the last report,” corresponding author Cara Libby, a technical executive at U.S.-based Electric Power Research Institute (EPRI) told pv magazine.

Several recyclers provided life cycle inventory (LCI) data about recycling processes, energy consumption and material recovery. Three of them were from Germany: Reiling Glas Recycling, LuxChemtech, and Flaxres, two from France, ROSI and Envie 2E Aquitaine, plus Italy-based Tialpi, Japan-based NPC and U.S.-based First Solar.

Looking at recycling data for both crystalline silicon (c-Si) and thin film cadmium telluride (CdTe) activity, it said, “Most processes are still under development or in a pilot stage, except for several mechanical process technologies for c-Si modules and First Solar’s recycling plants in the United States, Vietnam, Malaysia, and Germany for CdTe modules.” The reported recycled volumes ranged from 1,000 t/yr t to 50,000 t/yr.

The mechanical recycling, grinding, and crushing methods are the original, and probably most established and understood, but the outputs are not yet very pure. “We see an investment in dedicated equipment and new technologies, some scaling up too,” said Libby, highlighting water jet cleaning to remove back sheets, light pulse treatment to melt laminates so they can be peeled off, pyrolysis techniques, hot knife, and chemical methods.

When pv magazine asked if the PV industry itself might end up being the biggest market for the recovered materials, Libby answered, “It is indeed a very big market, but it may be challenging to use materials like silicon again in new products due to purity issues. It might be the same for glass. Very high purity materials are required for reuse in the PV industry.”

Patent activity and technology publishing

The team identified relevant PV recycling technology patents and literature, noting a “steep” increase in activity. A global patent search identified 456 patents, with 80% of patents targeting recycling processes for silicon-based modules, cell metals, polymers, glass, or devices.

Companies with the most patents were identified and ranked with the Korea Institute of Energy Research, followed by China’s Suzhou Goldway Technologies, First Solar, and Yingli, a Chinese module manufacturer. The next three companies in the ranking were from Japan, Tattori Resource Recycling, NPC which provides PV production and recycling equipment, and Daikin Industries.

The country ranking based on patent activity has China at the top with 141, followed by Japan with 85, South Korea with 79, the U.S with 54 and 33 for Germany,

The global literature search revealed 569 relevant papers and publications. The report noted that the number of publications has “ascended steeply since 2010”, which correlates with the “number of newly installed PV capacities” combined with “discussions and implementations” of the waste electrical and electronic equipment (WEEE) regulations in Europe. “Many countries are considering PV waste policies, and research interest is high,” it said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.