From pv magazine Global

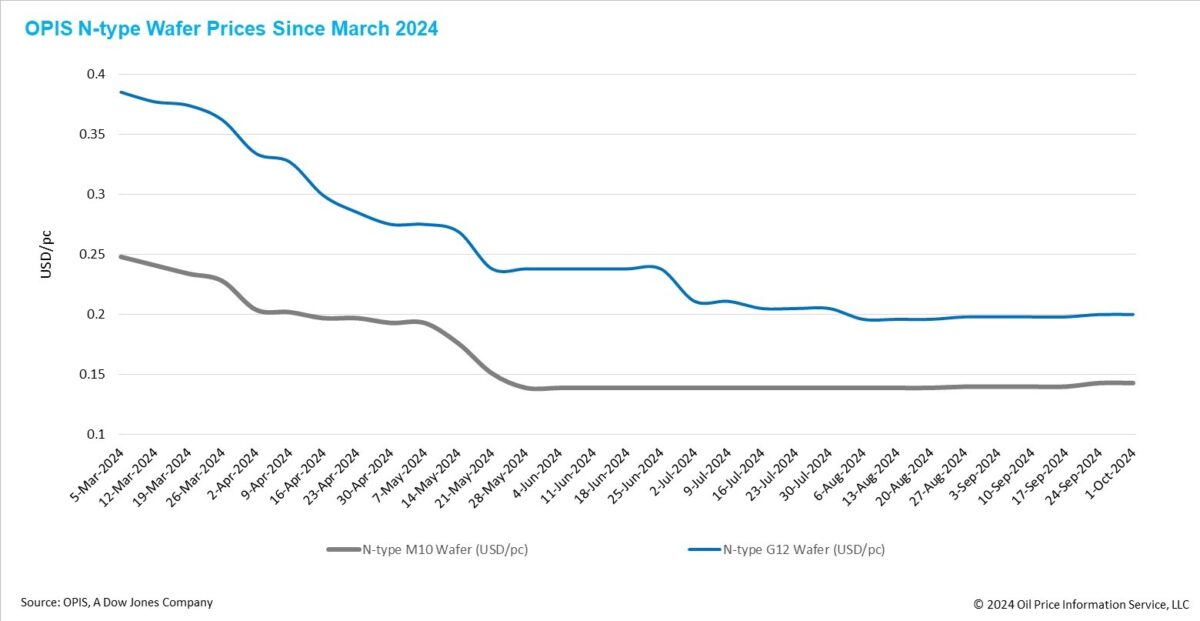

FOB China prices for wafers have remained stable across the board this week. Mono PERC M10 and n-type M10 wafer prices held steady at $0.145/pc and $0.143/pc, respectively. Likewise, Mono PERC G12 and n-type G12 wafer prices remained unchanged at $0.211/pc and $0.200/pc, respectively, compared to the previous week.

The supply-demand balance in the wafer market is improving as manufacturers have significantly lowered their operating rates in the past month. According to the Silicon Industry of China Nonferrous Metals Industry Association, China wafer production was 44.31 GW in September, a month-on-month decrease of 15.76%.

The low operating rate of wafer producers is likely to persist. During the China Golden Week holiday in early October, some wafer manufacturers reportedly scaled back production, reducing from the usual three shifts of production personnel per day to just one shift.

While the industry agrees that wafer prices have likely bottomed out and started intermittent rebounds, the challenge of raising prices is matched by the difficulty of clearing excess capacity. If prices increase, integrated manufacturers may boost their own wafer production and reduce external purchases, weakening demand for externally supplied wafers. Additionally, smaller factories might take this opportunity to restart operations.

Another uncontrollable factor in clearing excess wafer capacity is the weak downstream demand. China’s 14th Five-Year Plan aimed to reach 1,200 GW of combined solar and wind capacity by 2030, but this target was achieved by July this year, six years early. Insiders believe future solar installation growth may flatten, with an expected annual growth rate of around 10% under optimistic scenarios.

In the global market, a recent hurricane in North Carolina affected a mining area producing high-purity quartz (HPQ). An insider reported that a major HPQ supplier temporarily halted operations last week due to power outages and infrastructure damage. While the full impact is still uncertain and considered manageable by some sources, concerns have already emerged. The disruption in HPQ supply could drive up wafer costs or reduce wafer quality if lower-grade quartz substitutes are used.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.