From pv magazine Global

Scientists from Australia’s University of New South Wales (UNSW) and Chinese-Canadian PV module manufacturer Canadian Solar have investigated the degradation of industrial TOPCon solar cells subjected to accelerated testing conditions of 85 C and 85% relative humidity under the so-called damp heat test (DH85).

“Our findings highlight the vulnerability of TOPCon solar cells to contact corrosion, emphasizing the electrochemical reactivity of metallization as a potential risk for long-term module operation,” the research’s lead author, Bram Hoex, told pv magazine. “This study provides crucial insights into TOPCon cell degradation mechanisms, essential for optimizing performance and enhancing the long-term reliability of these modules.”

Hoex explained that the study is complementary to the research group’s previous work and expands it by using two types of sodium-containing salts which allowed the researchers to observe differences in the chemical reactions taking place. “This improved understanding of the underlying chemistry explaining the degradation is key to further improving the stability of TOPCon,” he added.

The group published a first paper in late April, in which it identified three new types of TOPCon solar module failures that were never detected in PERC panels. This work intended to assess the impact of bills of materials (BOM) on the reliability of both commercially available PERC and TOPCon solar cells.

“The results were quite surprising to us,” Hoex, told pv magazine at the time. “We expected polyolefin elastomer (POE) in general to perform well, but we identified that some POEs performed very poorly. This is likely due to the different additives used in the POE which react with the soldering flux and the metallization resulting in contact corrosion.”

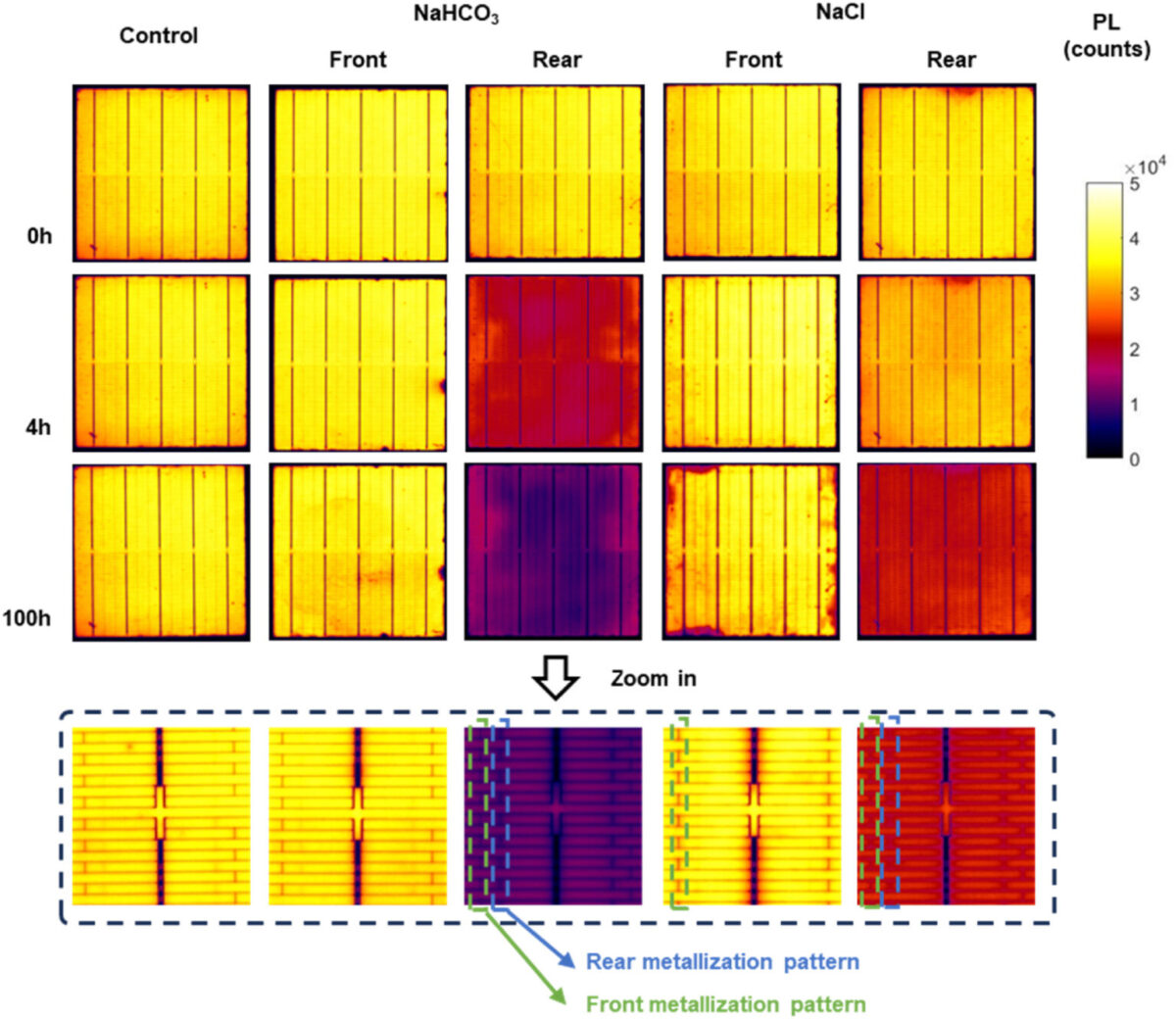

In the new research, the scientists found significant differences between the sensitivity of the front and the rear of TOPCon solar cells when degradation was induced by two sodium-containing salts – sodium bicarbonate (NaHCO3) and sodium chloride (NaCl).

The academics conducted the tests with 158.75 mm x 158.75 mm G1 n-type TOPCon solar cells with 5 busbars. Their average power conversion efficiency was 23.1 %.

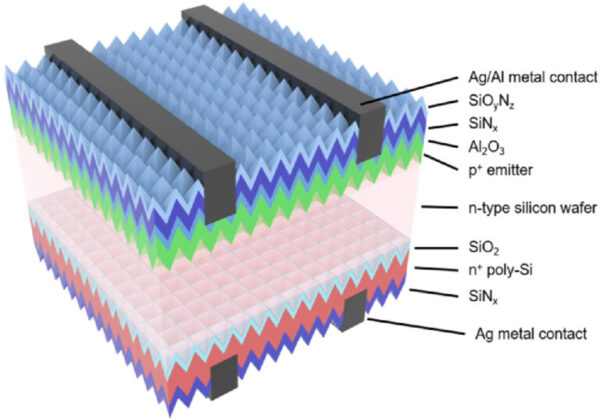

On the front side, the devices were made with a boron-diffused emitter covered with aluminum oxide (Al2O3) and silicon nitride (SiNx), as well as a silicon oxynitride (SiOyNz) stack providing surface passivation and acting as an antireflection coating (ARC). On the back side, the cells featured a TOPCon architecture based on a tunneling silicon oxide (SiO2) layer paired with a phosphorus-doped poly-Si layer, as well as a SiNx layer ARC.

“The front-side metallization comprised a combination of silver (Ag) and aluminum (Al, 3–5 at.%) as the conducting material, while the rear-side metal contact solely consists of Ag for conduction,” the researchers explained.

The DH85 test was conducted using scanning electron microscopy (SEM) images on five cell samples: reference cells only treated with deionized water (DIW); cells exposed to NaHCO3 at the front side; NaHCO3 at the rear side; cells exposed to NaCl at the front side; and cells exposed to NaCl at the rear side.

As for the first group, the scientists found that exposing TOPCon cells to high humidity at elevated temperatures for extended periods did not inherently lead to degradation. For the other groups, however, efficiency degradation was significant.

“Our accelerated test using NaCl causes extreme power conversion efficiency degradation resulting in a 92% relative reduction, while NaHCO3 results in a 5% relative efficiency reduction,” Hoex stated. “The primary degradation mechanism is a significant increase in series resistance (Rs), likely due to electrochemical reactions within the silver-aluminum (Ag/Al) paste.”

“When applied to the rear of the TOPCon solar cell, NaHCO3 increases recombination and deteriorates contacts, leading to a 16% efficiency reduction after only 100 hours of DH85 testing,” Hoex added. “In contrast, NaCl primarily increases recombination and does not seem to affect the contact, causing a 4% efficiency loss. Further investigation reveals degradation mechanisms in rear-side metal contacts, particularly oxidation at the Ag-Si interface.”

The scientists highlighted that Ag/Al pastes are exposed to long-term stability risks when exposed to ion-level contaminants and said other ion-level combinations should be investigated.

“In summary, this study unveils that TOPCon contact degradation mechanisms are significantly influenced by the combination of ions and paste compositions,” the researchers stated. “It offers crucial insights into the degradation patterns and underlying factors affecting the metal contacts of TOPCon solar cells, potentially aiding in the evaluation of module-level reliability.”

Their findings are available in the paper “Unveiling the origin of metal contact failures in TOPCon solar cells through accelerated damp-heat testing,” published in Solar Energy Materials and Solar Cells. The research team also included academics from Nantong University and Shanghai Jiao Tong University in China.

In another study published in early April, the same research team worked with scientists from Chinese panel maker Jolywood to design a laser-assisted firing process in TOPCon solar cell manufacturing that can reportedly increase contact quality and corrosion resistance, while also reducing production costs.

Called Jolywood Special Injected Metallization (JSIM), the new technique consists of a laser-assisted firing process that utilizes a customized silver (Ag) paste for the front contact formation on TOPCon solar cells. It is a low-temperature firing technique that is intended to facilitate paste penetration through the cell front anti-reflection coating.

“The JSIM technology is already in high-volume production by Jolywood and other companies are developing and implementing their own versions of laser-assisted firing as well,” the research’s lead author, Bram Hoex, told pv magazine at the time. “Jolywood was one of the first manufacturers to ramp up TOPCon technology in high-volume production.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.