The government’s move to extend the Approved Lists of Models and Manufacturers (ALMM) to solar cells from June 1, 2026, is accelerating the development of solar cell manufacturing in India.

CRISIL Market Intelligence and Analytics estimates the domestic PV cell manufacturing capacity will more than quadruple to 43-47 GW by June 2026 from 10 GW in March 2024. On the other hand, average annual demand is expected to be 40-45 GW between fiscals 2027 and 2030.

“While supply of solar cells should be enough based on current market announcements, there could be a transient shortfall till manufacturing ramps up,” says Sehul Bhatt, director- Research, CRISIL Market Intelligence and Analytics,

That means timely commissioning of projects announced so far will be critical to ensure capacity is adequate for demand — after considering the typical utilisation factor arithmetic and other imponderables.

Additionally, high prices of domestically manufactured cells may impact the tariff bids at solar power project auctions.

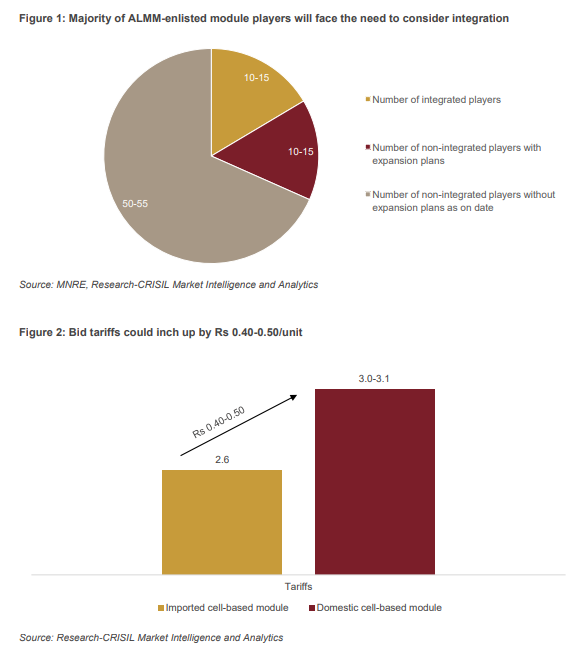

Bhatt says, “The prices of Indian solar cells today are 1.5-2.0x more than alternatives from China even after basic customs duty. Such high prices can drive up the capital cost of solar power projects by INR 5-10 million/MW and require tariff increase of 40-50 paise per unit as offset based on current market dynamics.”

The ALMM cell mandate could also pose challenges for companies that don’t develop domestic cell manufacturing capability as they would not be in compliance and could face module-supply challenges, which can impact their market share over the long term.

Says Surbhi Kaushal, Associate Director– Research, CRISIL Market Intelligence and Analytics, “Of the 62 GW of installed capacity as of December 2024 owned by 79 entities, only 13 have an integrated cell manufacturing base. The rest will have to decide between expanding capacity or competing for domestic cell supplies. Although 12 non-integrated players have announced plans to install 32 GW capacity by 2029, the relatively higher capital cost of cell manufacturing plants compared with module assembly lines, and falling prices of the solar value chain could slow things down.”

The CRISIL report says the industry has seen announcements of over 55 GW through the Production Linked Incentive (PLI) scheme and beyond. This augurs well because data shows cell-to-module integrated plants enjoy 2-6 percentage points better Ebitda margins than an only-module unit historically. Overall, the non-tariff barrier will protect domestic manufacturers that are vulnerable to global supply shocks and even aid exports as the US, a key market, continues to manufacture modules at 30-35% higher prices owing to lack of upstream components.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.