From pv magazine USA

“But what happens when the sun goes down?” This age-old refrain now has a definitive answer: “Batteries take over.”

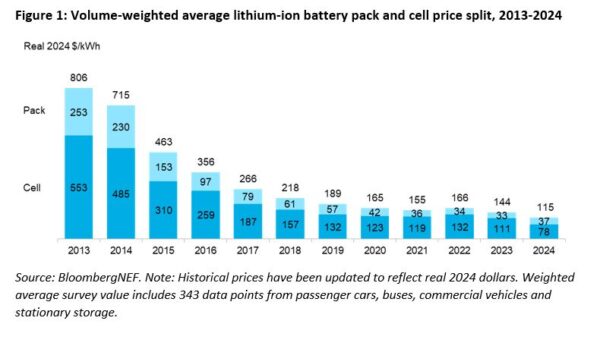

Throughout 2023 and 2024, lithium-based batteries have evolved from being merely useful, and somewhat expensive, to being on the brink of affordability and widespread deployment. This transformation has been driven by substantial reductions in cost and increases in manufacturing and deployment volumes.

But before we dive into those details, let’s first discuss why batteries are such a useful technology.

Imagine batteries as spacecraft or missiles, adjusting their trajectory with precise, quick bursts of energy. In astronautics, this is known as a “reaction control system,” an essential technology since the days of the first Apollo missions. Similarly, batteries are capable of delivering precise amounts of energy within milliseconds. This capability proved crucial when the world’s first large-scale battery installation prevented a blackout in Australia by responding more rapidly than traditional power plants could.

With their microsecond response times, batteries provide ultra-precise energy outputs that are critical in moments of sudden demand. This rapid response allows batteries to act more quickly than the slower, more cumbersome responses of traditional fossil-fueled plants. Recognizing the advantages of this rapid response, Australia was able to significantly shorten the required reaction time for power plants from 30 minutes to just 5 minutes.

Combined with grid-forming inverters, batteries are helping the power grid wean itself off the physical spinning masses that have traditionally provided stability during complex grid events.

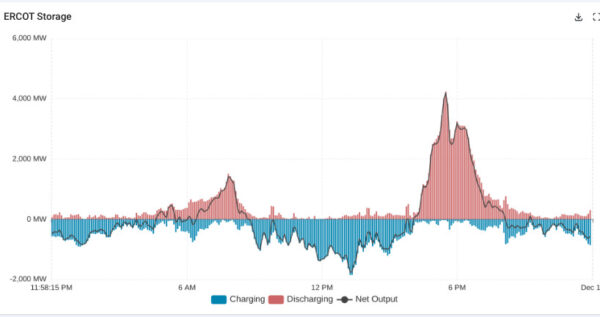

The microsecond reaction time not only enhances grid stability but also enables battery developers to maximize revenue when power prices spike. The graph below from GridStatus.io illustrates how batteries in Texas capitalize on their nimble reaction times by charging during lower-priced, solar-powered periods and discharging during peak price times, effectively stabilizing energy costs.

Batteries are distributed

Large and small battery installations alike are making headlines. In 2018, Vermont used a mix of residential and grid-scale batteries to save ratepayers on utility-level demand charges, achieving a savings of $6.7 million on one warm summertime Tuesday. The following year, Sunrun earned the trust of the New England System Operator by integrating 5,000 residential solar and storage installations, marking some of the first virtual power plants in the United States.

Imagine if 300 million electric vehicles (EVs) in the U.S., including cars, buses, trucks, and fleet vehicles, were all connected to the grid. Each with an average battery size of 75 kWh, they would collectively offer about 22.5 TWh of capacity, enough to power the country for two days. Because vehicles tend to follow human beings, they’re generally positioned strategically to deliver electricity precisely where it’s needed.

Perhaps, in the not-too-distant future, it will become a social faux pas not to plug in your vehicle, much like recycling or turning off the lights when you leave a room.

Extending this concept, consider every residential, commercial and industrial building, along with electric substations, all equipped with substantial batteries. Together, they would form a vast network, contributing to a balanced power grid. This network would seamlessly integrate mobile and stationary storage solutions to meet demand across diverse locations, ensuring a reliable and responsive energy system.

To continue reading, please visit our pv magazine USA website.

Author: John Fitzgerald Weaver

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.