NTPC Green Energy Ltd (NGEL) and Bharat Light and Power (BLP) signed a Memorandum of Understanding (MoU) to jointly explore the off-take of green hydrogen and its derivatives from NGEL and its affiliates to third parties. Opportunities for selling captured carbon or biogenic carbon from NGEL will also be in scope. NGEL, or through its affiliates, shall set up infrastructure required for functioning of the green hydrogen project including RE projects and regular operation under buid-own-operate mode. BLP builds, owns and operates renewable energy power plants to generate clean energy through renewable sources.

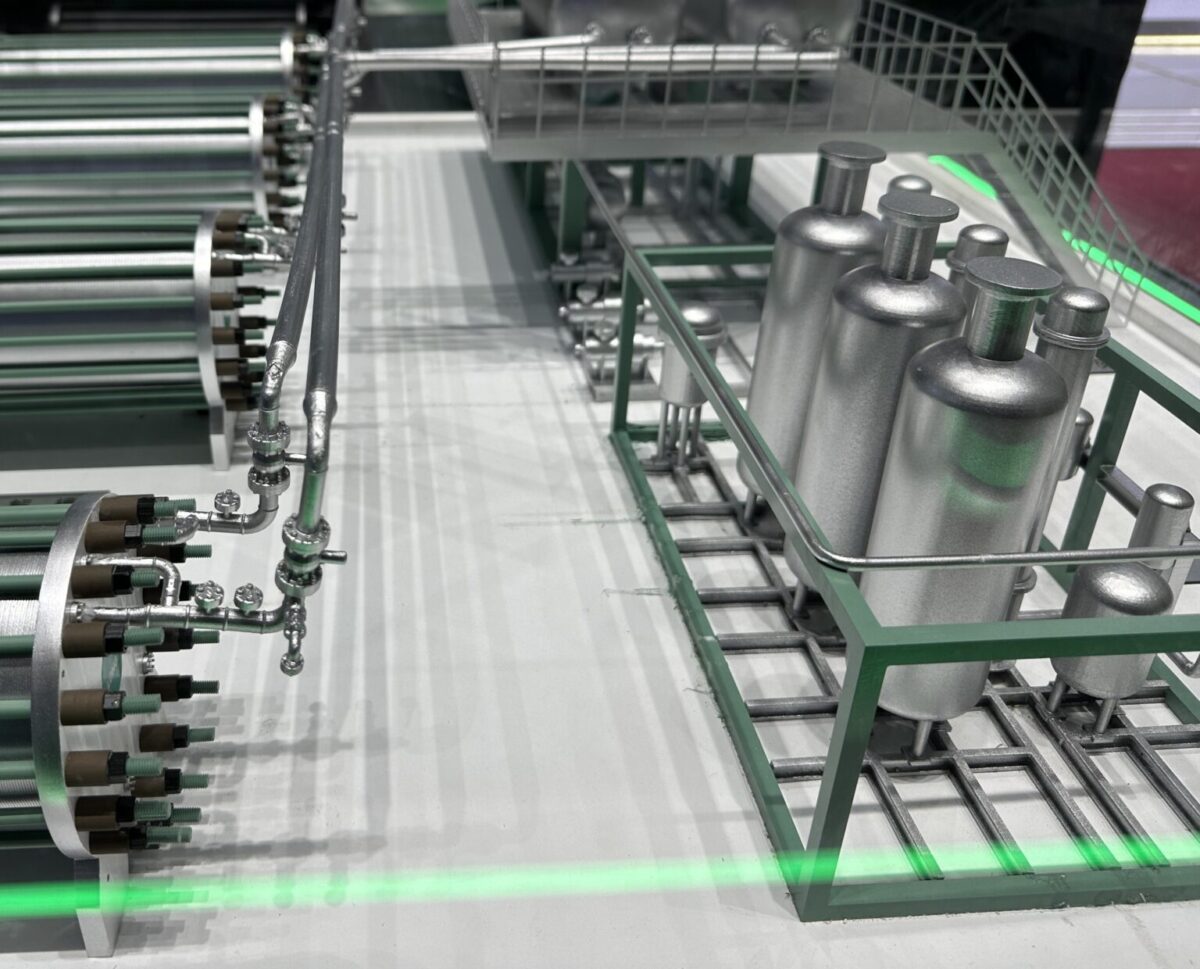

NLC India, Neyveli, a state-owned Indian company engaged in lignite mining and power generation, has invited bids for setting uo a 4 MW PEM (proton exchange membrane) electrolyser based green hydrogen plant at Neyveli, Tamil Nadu. The scope of work includes design, engineering, manufacturing, inspection, testing, supply, packing, forwarding, transport & unloading at site construction, erection, testing, commissioning, trial operation, and operation and maintenance of the plant.

AMPIN Energy Transition and Air Water India have signed an MoU for on-site green hydrogen development. The collaboration targets 200 MW capacity by 2027, using both PEM and alkaline electrolyser technologies. The partnership combines AMPIN’s expertise inrenewable energy development with Air Water’s experience in operating industrial gas plants.

A group of Saudi-Algerian researchers underscored Algeria’s ability to leverage solar energy across diverse regions, suggesting that ad-hoc programs like MedHySol and HySolThane could make the Northern African country a global hydrogen player with green hydrogen production costs as low as $4 per kilogram. “Current estimates suggest that the cost of producing green hydrogen using photovoltaic energy in Algeria ranges between $4 and $6 per kilogram, owing to its low solar electricity cost of $0.04/kWh,” said the researchers. The researchers also wrote in “Advancing green hydrogen production in Algeria with opportunities and challenges for future directions”, recently published in Scientific Reports, that Algeria could either use seawater or wastewater for the electrolysis, adding that local hydrogen production would increase local energy security and reduce emissions.

GreenGo Energy signed a deal with Mauritania’s government on more than 100,000 hectares of land near Nouakchott to develop a scalable project. “The Megaton Moon Project adopts a phased approach to scalability, ensuring alignment with market demand and supply chain readiness between 2029 and 2033. Full capacity will include 6 GW of electrolysis, 6.8 GW of onshore wind, and 6.3 GW of solar PV,” said the Danish developer in an email. Phase 1, set for completion by the end of 2029, will deploy 500 MW of electrolysis, 600 GW of onshore wind, and 600 GW of solar PV, producing approximately 339,000 tons of green ammonia annually.

European technology providers, project developers, producers, infrastructure operators, market stakeholders, and users active across the entire hydrogen value chain asked for continued financial incentives and a revision of European hydrogen rules “to bridge the gap between EU hydrogen ambitions and market realities.” The 17 co-signatories highlighted a large gap between political vision and market reality, non-competitive renewable and low-carbon hydrogen production costs, and underinvestment in infrastructure for producing and transporting hydrogen.

TotalEnergies signed agreements with Air Liquide to develop two projects in the Netherlands involving the production and delivery of around 45,000 tonnes per year of green hydrogen using renewable electricity, the majority from the OranjeWind offshore wind farm, developed by TotalEnergies (50%) and RWE (50%). TotalEnergies (50%) and Air Liquide (50%) have set up a joint venture to build and operate a 250 MW electrolyzer near the Zeeland refinery, whose commissioning is expected in 2029.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.