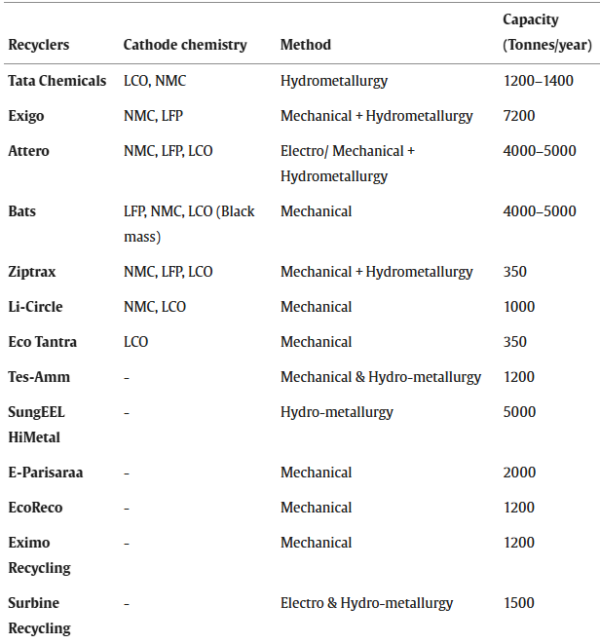

A new study report by Vellore Institute of Technology (VIT) researchers shows that at least 13 companies are engaged in spent lithium battery recycling in India. Out of these, seven have been using hydrometallurgical processes that involve using aqueous solutions to extract metals from the battery components. These include Attero, Exigo, SungEEL HiMetal, Surbine Recycling, Tata Chemicals, Tes-Amm, and Ziptrax.

Energy Reports

Volume 13, June 2025

The lithium battery recycling landscape in India is driven by a significant growth in the consumption of lithium batteries with increasing adoption of electric vehicles, renewable energy projects, and portable electronic devices.

The report states that India will require 132 GWh of lithium-ion batteries annually by 2030. The cumulative lithium-ion battery market size is projected to increase from 2.9 GWh in 2018 to reach about 800 GWh by 2030.

The report highlights material collection as a major challenge with spent battery recycling in India. “In the Indian context, the problem of material collection is particularly acute as the unorganised sector handles the collecting of electronic waste, and the general public is unaware of the advantages of recycling,” states the report. “Without implementing a plan and policy for collecting these old batteries, we can see the effects of disposal and the risks it poses to the ecosystem.”

End-of-life battery collection and shipping involves several operators and a large geographic area. Thus, workers need to be well-trained and have access to the right tools to ensure the batteries don’t get damaged, though they are hazardous materials. Safety standards and oversight are essential to maintain the safety conditions during these stages, states the report.

Further, the report states that lithium-based chemistry is still being developed to increase energy density, efficiency, and safety. As a result, recycling companies face several difficulties in accurately identifying and recovering material from various batteries. Different chemistries of lithium batteries necessitate distinct recycling procedures.

Despite these obstacles, India’s recycling ecosystem offers an opportunity to establish efficient and environment friendly lithium battery recycling methods. The increasing use of lithium batteries generates a need for specific recycling facilities in India.

India is currently dependent on imports to fulfill nickel and cobalt requirements. If these materials are obtained locally through recycling, battery producers in India will conserve costs, adds the report.

Recognizing the importance of battery recycling, the Indian government is attempting to create conducive legislative frameworks. The Ministry of the Environment, Forests, and Climate Change (MoEFCC) proposed the Batteries (Management and Handling) Rules 2022 to create a legislative framework for battery collecting, recycling, and ecologically sound disposal.

The report recommends an integrated approach for effective Lithium-ion battery recycling. It adds research institutes and industry alliances will play a critical role in advancing recycling methods and technologies. Continued R&D efforts may result in the design of effective and affordable recycling systems customized to the Indian setting.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.