Researchers from Poland’s AGH University of Krakow and Singapore’s Solar Energy Research Institute of Singapore (SERIS) have developed a novel method for recycling crystalline silicon PV panels. Their findings show that the electrohydraulic shockwave fragmentation (EHF) technique enables the recovery of more than 99.5% of the weight of the panels, almost complete recyclability.

“This research was carried out at two locations,” corresponding author Professor Pradeep Padhamnath told pv magazine. “The EHF machine is situated at SERIS, Singapore where the disintegration of the modules was carried out. The analysis of the products and the further development of the recycling process was carried out at AGH University of Krakow.”

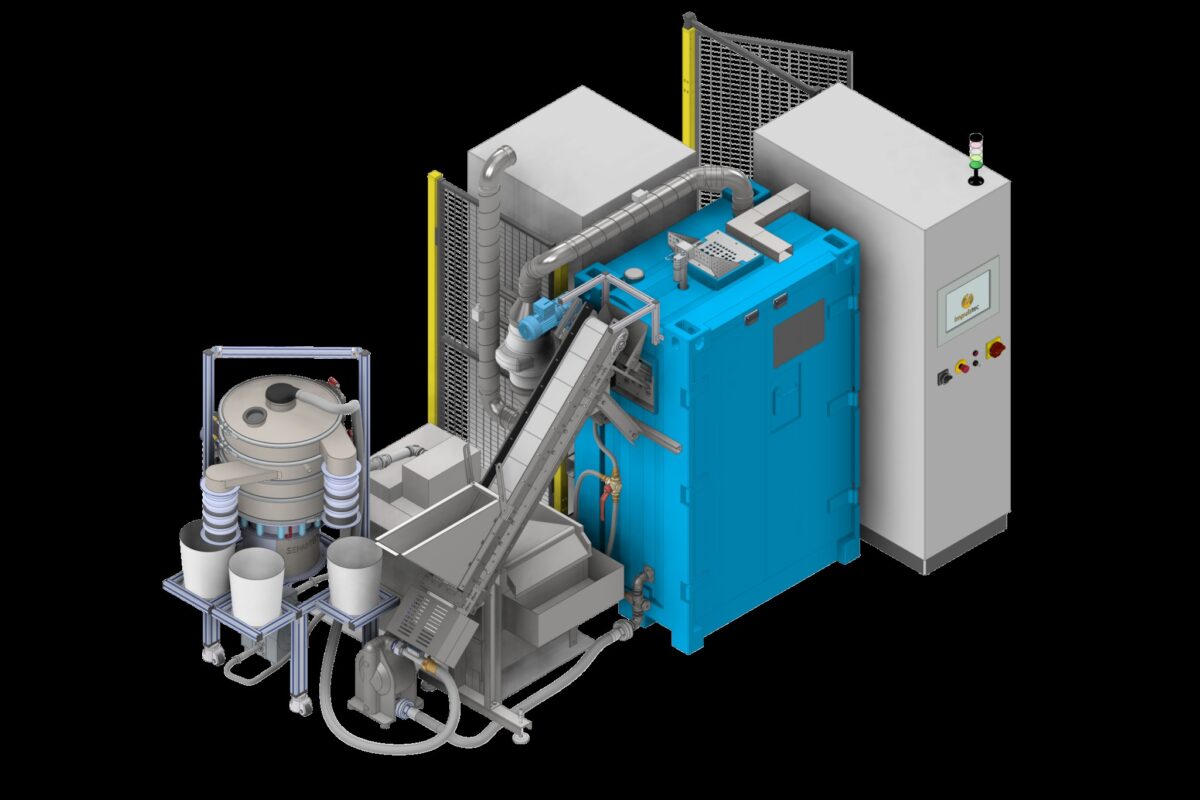

The EHF machine relies on shockwaves generated by arcing between electrical electrodes suspended in a liquid medium. In this case, electrical electrodes are connected to a power supply of approximately 50 kV, generating shockwaves in water as they interact with the chopped-down PV module that is immersed in the liquid. Before that happens, the aluminum (Al) frame, the external junction box, and the wires are removed by mechanical separation, and the module is cut with a water jet.

The processes

After the disintegration in the fragmentation unit, individual materials such as glass, backsheet, ethylene vinyl acetate (EVA), copper (Cu) ribbons, and solar cells are separated by filtration, sorting, and binning as they pass through different sieves. The materials can then be used to extract silicon (Si) and silver (Ag) through downstream chemical processes, while the glass, Cu/Al/Ag contacts can be reused post-purification and melting.

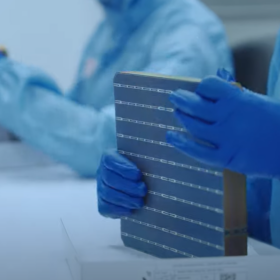

The group tested the technique on three different panel types, namely glass-backsheet, glass-glass, and glass-free panels. They were all created in-house without working cells in a process similar to the one in which working panels are made. Glass-glass panels had a layer of glass on both sides, with an EVA copolymer-based layer as the encapsulant. Glass-backsheet panels had glass on the front and polyethylene terephthalate (PET) on the rear, with EVA as the encapsulant. Glass-free panels had PET-based transparent front sheets on the front and opaque backsheet on the rear with EVA as the encapsulant.

All the panels were cut into either 2.5 x 2.5 cm or 5 x 5 cm pieces and were inserted into the EHF for either 240, 480, or 720 seconds (4, 8, or 12 minutes, respectively). After that, recovered products were small pieces of glass (1-5 mm), coarse powder (over 250 μm), and fine powder (less than 250 μm) that contained mostly Si, Al, and Ag. “The fine, small size of the particles enables quick chemical reactions due to the enhanced surface area and hence could improve the process throughput in industrial applications,” explained the academics.

To recover Al, the powder was treated with sodium hydroxide (NaOH); while nitric acid (HNO3) was used to recover Ag. Hydrofluoric acid (HF) was used to recover Si, creating silicon tetrafluoride (SiF4) as a byproduct. “The SiF4 gas is of commercial importance and has multiple uses in the semiconductor and chemical industries. Using this process, the gas can be recovered at this point and stored for future uses,” the team has highlighted.

In addition, the glass pieces were treated with potassium hydroxide (KOH) to separate the EVA and PET. “A significant advantage of this process is the recovery of the various polymers used in the PV panel, such as EVA and polymer backsheet, which can be recycled,” the team concluded. “In pyrolysis process these polymers are burnt and lost, generating toxic fumes in the process. Hence, this process provides a cleaner and less energy intensive alternative to recover materials from the PV panels leading to almost complete circularity.”

The new recycling technique was presented in “Development of PV panel recycling process enabling complete recyclability of end-of-life silicon photovoltaic panels,” published in Solar Energy Materials and Solar Cells.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.