A group of researchers from the University of Oxford in the United Kingdom and China’s metallisation paste specialist Changzhou Fusion New Materials has identified a new failure mode in TOPCon solar modules manufactured via the so-called laser-enhanced contact optimisation (LECO) process.

The process is carried out after the firing of the metallisation paste and involves scanning a laser across a crystalline silicon cell while it is under reverse bias. The result is that free carrier electrons are forced between the metal contact and the silicon, creating a new structure on the edge of the contact and boron emitter layer surface – a current-fired contact (CFC). By virtue of the new CFC structure, TOPCon cells that undergo the LECO process demonstrate no contact resistivity after thermal cycling.

“This process induces a localised high current density at the contact interface, promoting interdiffusion between the silver and silicon materials, which reduces contact resistance and improves cell efficiency,” the scientists explained, noting that efficiency gains may reach up to 0.6%. “LECO is especially effective in TOPCon cells, where it helps achieve low contact resistivity while maintaining good interface passivation at the p-side, thus enhancing open-circuit voltage and fill factor simultaneously.”

The research team investigated, in particular, a degradation in series resistance affecting TOPCon cells after temperature and bias treatment. It also explained that its work has built on previous scientific research demonstrating that applying a current during the thermal process can increase series resistance “by an order of magnitude.”

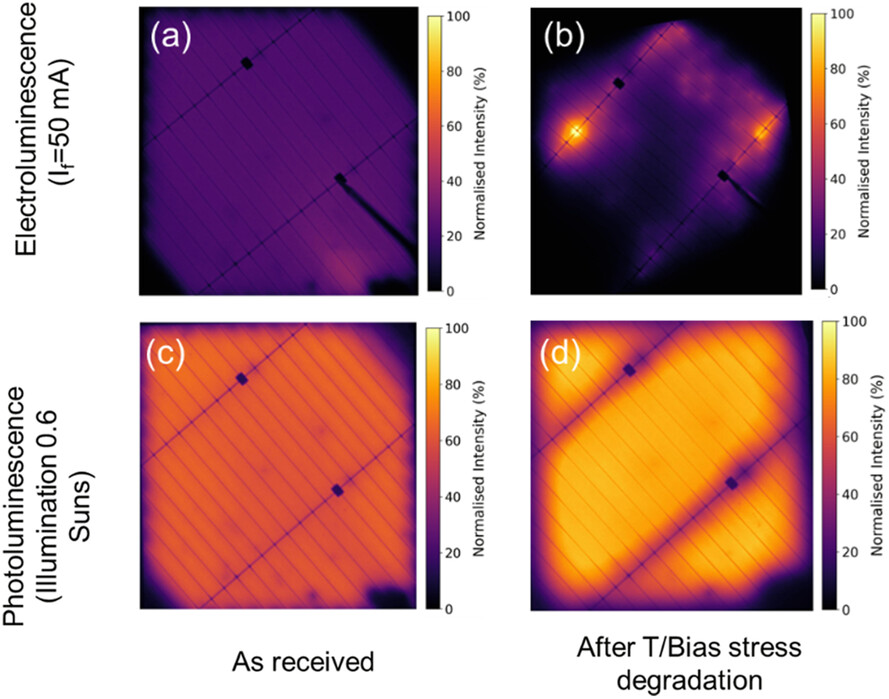

The academics conducted in situ I–V monitoring during a 400 C annealing process of both conventional and LECO-treated TOPCon solar cells and applied independent bias cycles in a forward–reverse-forward–reverse order. Furthermore, they used electroluminescence (EL) and photoluminescence (PL) to assess the spatial distribution of series resistance and cell passivation quality.

During the first cycle of forward bias, the scientists observed a constant growth in series resistance, while in reverse bias they found a slight decrease in series resistance.

“Such degradation aligns with previously reported findings in the literature, which attributed the resistance increase to the passivation of the silver/n+-polysilicon interface,” they specified. “When analysing the LECO-TOPCon cells, the forward bias condition leads to a decrease in series resistance, which is the opposite of what was observed in conventional TOPCon cells. Most staggeringly, the reverse bias in LECO-TOPCon severely degrades the series resistance, increasing it by over two orders of magnitude for the duration of 30 min.”

The researchers warned that, if not addressed, the observed series resistance degradation could affect both the performance and economic viability of LECO-treated cells.

“Further investigations are required to understand the microscopic nature of this reliability issue and explore potential mitigation strategies for enhancing stability under operational conditions,” they concluded.

Their findings are presented in the study “A Failure Mode Affecting the Reliability of LECO-Treated High-Efficiency TOPCon Solar Cells,” published in RRL Solar.

Last year, scientists from the University of New South Wales (UNSW) and Chinese-Canadian PV module manufacturer Canadian Solar demonstrated the degradation of industrial TOPCon solar cells subjected to accelerated testing conditions of 85 C and 85% relative humidity under the so-called damp heat test (DH85). The primary degradation mechanism in this research was a significant increase in series resistance.

From pv magazine Global

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.