Bluetti launches 350 W portable solar module

The new product relies on 23.4%-efficient solar cells and features a short-circuit current of 10.8 A. It can be folded into a briefcase and is claimed to be an ideal solution for camping and outdoor activities.

UK government warns of global warming risks related to hydrogen leaks

The UK Department for Business, Energy and Industrial Strategy has published new research showing that hydrogen leaks could have an indirect climate-warming impact, partly offsetting efforts to reduce carbon dioxide emissions.

Pure solid state batteries from Switzerland

Swiss Clean Battery is set to start commercial production of its pure solid state batteries in Switzerland. The batteries are based on a protected electrolyte made of a solid ion conductor, which helps to maintain internal resistance and capacity. The fixed ion conductor is formed in the battery cell itself, similar to a multi-component adhesive.

Bosch unveils hydrogen-compatible stationary fuel cell system

Bosch’s new solid oxide fuel cell prototype has an electrical efficiency of more than 60% and an overall efficiency above 85%. It also has a targeted power output of 10 kW and can produce up to 3 kW of thermal energy.

Aluminum-nickel molten salt battery for seasonal renewables storage

US scientists have developed a battery that can retain 92% of its initial capacity over periods of 12 weeks, with a theoretical energy density of 260 W/hour per kg. It was built with an aluminum anode and a nickel cathode, immersed in molten-salt electrolyte.

Modular electrolyzer for residential, commercial applications

Germany’s Ostermeier H2ydrogen Solutions has developed an electrolyzer that works with tap water, with bottles to store hydrogen and a fuel cell or a Wankel engine to produce electricity. The system has a capacity ranging from 1kW to 100 kW, which corresponds to hydrogen production of 0.2-20 Nm3/h.

SMA unveils new inverter for residential, commercial PV

SMA is offering a new line of four inverters with power ratings of 12kW, 15kW, 20kW and 25kW, for use in rooftop PV systems up to 135kW in size. It claims the inverters provide grid-compliant power control of entire systems and enable over-dimensioning of PV arrays by up to 150%.

French consortium develops self-cleaning solar module coating

French chemical company Axcentive and solar module manufacturer Photowatt have developed a PV panel coating based on photoactive nanotechnology. The coating relies on a super-hydrophilic surface that makes the water spread out on the module surface immediately, thus avoiding light scattering effects upon rain.

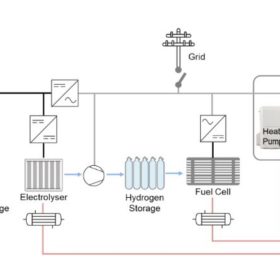

Designs for solar+storage+hydrogen systems in buildings

German scientists have tried to determine whether a PV system linked to a small electrolyzer, a fuel cell, and lithium-ion batteries could fully power a grid-connected household. Their new proposal consists of a 6.8kW PV array, a 5kW electrolyzer, a 1.24kW fuel cell system, and battery storage.

Hungarian start-up launches solar tile with output of 167W per m²

Developed by Hungarian manufacturer Terràn, the Generon solar tile is based on concrete support and weighs is in at 5.7kg.