PV technology roadmap: More work needed to process 210mm wafers

In an update to its annual International Technology Roadmap for Photovoltaics, German engineering association VDMA discusses the readiness level for various technologies in PV cell and module manufacturing, finding that more process development is needed for 210mm wafers – the largest format currently on the market – to match the throughputs that will soon be achievable with smaller formats including 182mm.

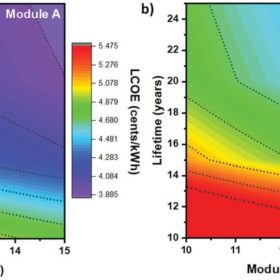

Mathematical model to predict rooftop PV system yield

Scientists in India developed a mathematical model to predict the output of solar cells and modules in the field. The model was developed and tested using both sun simulator and actual installed modules. The scientists state that their model can be applied to a PV installation anywhere in the world, and that by taking into account module degradation over time their forecasts can be as much as 26% more accurate than existing energy yield models.

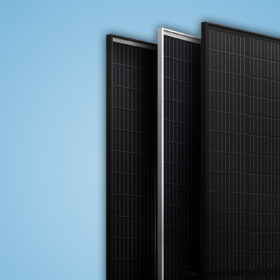

210mm wafer achieves highest energy yield, finds Trina Solar

Trina Solar has found that its Vertex modules, based on the 210mm wafer, achieve an energy yield up to 1.6% higher than rival products based on the smaller 182mm wafer format. The company conducted outdoor testing at two separate sites with varying climates, finding that products based on the larger format have a particular advantage in low-irradiance environments.

Analyzing the opportunity for perovskite solar module production in India

Scientists in India conducted a techno-economic analysis for a 100 MW production line for carbon-electrode perovskite solar modules, located in Himachal Pradesh, India. The analysis concludes that, even at the smaller scale, this emerging technology could achieve cost levels comparable with today’s silicon solar products.

Big modules head for standardization

PV manufacturing giant Trina Solar says it has agreed with other industry players on a set of standard dimensions and other technical specifications for PV modules utilizing 210mm wafers – the largest currently available on the market. The manufacturer says it expects the China Photovoltaic Industry Association to formally release the standard before the end of October.

Module durability, and design for recycling

A new report published by the International Energy Agency offers a series of guidelines for the design of recyclable PV modules. The report aims to help manufacturers find the balance between durability and recyclability, to better address concerns about the 78 million tons of end-of-life PV modules expected by 2050.

JinkoSolar sets new record for n-type solar cell efficiency

Manufacturing giant JinkoSolar has set another world record for n-type solar cell efficiencies with its TOPCon technology, this time pushing to 25.4%. The new world record was confirmed by JET laboratories in Japan, and surpasses JinkoSolar’s previous record of 25.25% set back in May.

Reliance Industries acquires 100% stake in REC Group, plans new manufacturing bases

India headquartered multinational Reliance Industries, through its subsidiary Reliance New Energy Solar Limited, yesterday announced the acquisition of Norway headquartered module manufacturer REC Group. The move comes as Reliance pushes forward with its US$10 billion plan to move in on the renewable energy industry, having also this week announced acquisition of a 40% share in EPC provider Sterling & Wilson.

A new spin on battery manufacturing

Scientists in Germany developed a new process for manufacturing battery electrodes, that they say could be both more cost effective and environmentally friendly compared to current technologies. The technique could be applied to a range of different battery materials/chemistries and its creators say they are in discussion with a number of battery cell manufacturers regarding pilot production.

Novel battery chemistry for zinc-ion batteries

Scientists have demonstrated a zinc-ion battery that overcomes many of the challenges for this technology. By working with a highly-concentrated salt solution as the electrolyte, the group was able to achieve stability over more than 2,000 cycles combined with a strong electric performance. The group says that its work opens up “a viable route to developing aqueous batteries for emerging electrochemical energy storage applications.”