Lithium saturation to make old batteries new

Scientists investigating the aging mechanisms affecting today’s lithium-ion batteries observed that the loss of lithium over time is one of the main causes of performance loss. With this in mind, they developed and tested a “relithiation” process that promises to eliminate much of the cost and complexity from recycling battery components and materials.

Graphene aluminum ion batteries with ultra-fast charging

The “graphene revolution” is almost here. Australian scientists specializing in aluminum-ion batteries are now working with Brisbane-based Graphene Manufacturing Group to commercialize a technology that could transform energy storage.

Ola to provide 100,000 charging points for electric two-wheelers

Ola has announced it will set up a Hypercharger Network for its electric two-wheeler customers. The company claims the charging network would be the world’s largest and densest, spread over 400 cities with more than 100,000 charging points.

CSC partners Tata Power on installation of solar-powered microgrids and water pumps

Tata Power brings technology and financial strength to set up the distributed, small-scale solar power systems in rural areas and provide round-the-clock power supply to households and businesses. CSC brings to the partnership village-level entrepreneurs to provide quick, low-cost service support.

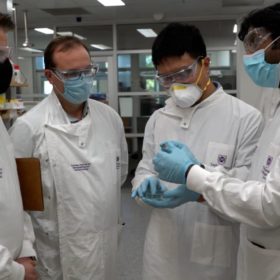

Nickel-salen for a battery that charges in 10 seconds

Scientists in Russia introduce a promising new material for battery energy storage, the product of more than three years of research. Incorporating a nickel-salen polymer into the cathode, the group demonstrated a battery that can charge and discharge ten times faster than today’s lithium-ion batteries. And though the battery still lags in terms of overall capacity, the group is confident that its discovery will lead to big improvements for lithium batteries.

Waaree Energy Storage System secures seed funding of US$2 million

The energy storage manufacturer will use the funds to expand its manufacturing capabilities, and aid product development with emphasis on smart Internet of Things (IOT) based batteries and telematics.

IISc sets up off-grid EV charging station powered by Vikram Solar modules

The Indian Institute of Science (IISc), Bangalore has set up a solar-powered charging station to conduct the system’s impact assessment. The system—designed by UK-based renewable energy advisor GreenEnco—uses Vikram Solar’s 16 mono PERC solar modules of 400 Wp each, a hybrid inverter, and battery storage.

An aluminum battery that can charge in a fraction of a second

Scientists in China and the United States investigated the inner workings of aluminum-ion batteries. With new insights into mechanisms at work within the battery during cycling, the group was able to demonstrate a battery capable of ultrafast charging, with the highest capacity so far reported for an aluminum battery.

The long read: Nickel and dime batteries to LFP

Lithium-ion phosphate batteries are making a comeback. Thanks to high nickel prices and limited feedstock supply, the EV industry is driving this change. There is no need to fret about the onset of slightly lower energy density, though, as this development has some benefits for the stationary storage market.

Indian electric rickshaw market could hit US$1.4 billion by 2025

The electric rickshaw market would grow at 33.3% annually over five years to touch $1,394.2 million by 2025.