LUCAS TVS plans 10 GWh lithium-ion battery fab in Tamil Nadu

The Indian auto-components manufacturer will set up a semisolid lithium-ion cell manufacturing facility in Chennai under a technology licensing agreement with American startup 24M. The first phase of the planned 10 GWh fab would start production in the second half of 2023.

Lithium-ion vs lead-acid batteries

An international research team has conducted a techno-economical comparison between lithium-ion and lead-acid batteries for stationary energy storage and has found the former has a lower LCOE and net present cost. Through their analysis, which was performed assuming the use of the batteries in connection with a 10 kW, grid-tied PV system, the scientists concluded that lithium-ion batteries are the most viable solution.

Ez4EV to deploy mobile charging stations for electric vehicles

The mobile electric vehicle chargers will be deployed in cities and highways across India, mitigating the range anxiety among electric vehicle (EV) owners. These are equipped with a range of slow and fast chargers to support two-wheelers to commercial vehicles to premium EVs.

Cheapest long-duration storage for systems with high renewables

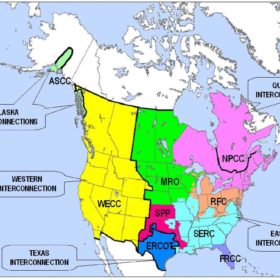

National Renewable Energy Laboratory researchers have studied which tech offers the lowest levelized cost of energy to provide the US Western Interconnection grid with electricity when wind and solar are not available. They assumed 85% renewables penetration and determined that geologic hydrogen storage and natural gas combined-cycle plants with carbon capture storage are the cheapest options for 120-hour discharge applications.

Novel battery chemistry for zinc-ion batteries

Scientists have demonstrated a zinc-ion battery that overcomes many of the challenges for this technology. By working with a highly-concentrated salt solution as the electrolyte, the group was able to achieve stability over more than 2,000 cycles combined with a strong electric performance. The group says that its work opens up “a viable route to developing aqueous batteries for emerging electrochemical energy storage applications.”

The long read: Hot thermal energy storage hopes

Thermal energy storage is dense, efficient, and suitable for greenfield and brownfield projects, with a potentially long lifespan. It can also be built with recyclable or low-impact storage materials. So why is it taking so long to achieve widespread commercial success? Tristan Rayner explores the latest developments.

India planning to call bids for 4 GW electrolyzer capacity

Currently, the cost of producing green hydrogen ranges from 3.6 to 5.8 USD/kg depending on the renewable energy mix and electrolyzer technology. Scaling the electrolyzer production globally will help drive down green hydrogen costs.

Combining big floating solar with hydropower

Scientists in Bangladesh have evaluated how a 50 MW floating PV plant could be integrated with the 230 MW Karnafuli Hydroelectric Power Station, located at the Kaptai Dam on the Karnaphuli River. They found that the two energy sources can be perfectly optimized and that PV can compensate for the reservoir’s shortage of water storage during the winter season while hydropower can compensate for the poor yields of the floating array during the monsoon season.

Gravity-based renewable energy storage tower for grid-scale operations

Energy Vault secured $100 million in Series C funding for its EVx tower, which stores gravitational potential energy for grid dispatch.

The long read: Scaling up standalone power systems

As technology redefines the delivery of network services, grid operators in remote areas the world over are searching for more cost-effective and reliable alternatives to traditional poles and wires. Standalone power systems are the solar application that is at the forefront of the switch, and they’re ramping up fast.