The long read: The state of solid-state batteries

Solid-state batteries hold the potential to overcome many of the limitations of today’s lithium-ion storage technologies. Though they have been a research topic for more than 30 years, and more recently have seen billions of dollars poured into their development by leading carmakers and electronics giants, commercial development is still extremely limited. Major roadblocks remain in the way of both device performance and industrial-scale processing. pv magazine recently caught up with solid-state’s research community for a look at where the technology stands.

Odisha invites EoI for Konark solarization

Manufacturers and integrators of solar-based drinking water kiosks, solar trees, solar street lighting systems, and e-rickshaw charging infrastructure can submit their interest by August 29.

Keltron to set up a supercapacitor manufacturing unit in Kannur

The state-owned electronics manufacturer has signed a memorandum of understanding for technology transfer with Vikram Sarabhai Space Centre of Indian Space Research Organisation.

Energy storage investment to approach $10bn in 2025

Analyst IHS Markit has predicted storage will rebound this year following its first year-on-year decline in 2019. The technology is being rolled out at pace despite Covid-19 with state-level policies set to keep the US the global capital for the next five years.

ION Energy’s analytics selected for 581 MWh of large-scale battery storage projects

US-based esVolta will deploy the Edison Analytics software platform across its battery energy storage projects in North America. The software is expected to result in savings of $450,000 annually for esVolta by reducing excess battery degradation through improved heating and discharge management.

Sona Comstar, IIT Delhi launch incubation program for EV startups

The program aims at supporting the development of innovative electric vehicle (EV) solutions like extending range through battery capacity improvements, and battery management, fast charging infrastructure, and mobile charging solutions for emergencies. Two startups shall be supported each year with up to INR 80 lakh each to complete proof of concept and develop prototypes.

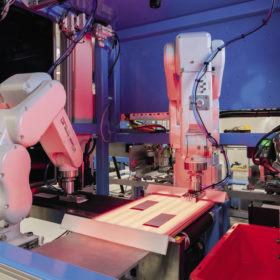

The long read: Independently evaluating battery quality

Companies investing in battery energy storage have historically relied on trust in the major brands supplying the batteries and complete systems. However, with the absence of international manufacturing quality standards, increasing price pressure on major brands, and the proliferation of low-cost manufacturers, buyers and investors are being forced to address quality risks with batteries. Ian Gregory and Benjamin Sternkopf of PI Berlin discuss the need for independent quality assessment in energy storage.

Government allows sale, registration of electric vehicles without pre-fitted batteries

Delinking the battery (which accounts for 30-40% of the total vehicle cost) will bring the upfront cost of the electric 2-wheelers (2W) and 3-wheelers (3W) to be lower than internal combustion engine counterparts. The battery could be provided separately by the original equipment manufacturer or the energy service provider.

TERI, FTI Consulting partner on hydrogen roadmap research

The Indian energy thinktank and the US-based consulting firm will research to demonstrate the viability of hydrogen as a sustainable solution for India’s energy needs.

Indian researchers develop low-cost, durable catalyst for hydrogen production

Researchers from India’s Centre for Nano and Soft Matter Sciences (CeNS) have developed a coordination polymer based catalyst for hydrogen production that exhibited exceptionally high durability for 70 hours at a high current density of −300 mA/ cm2.